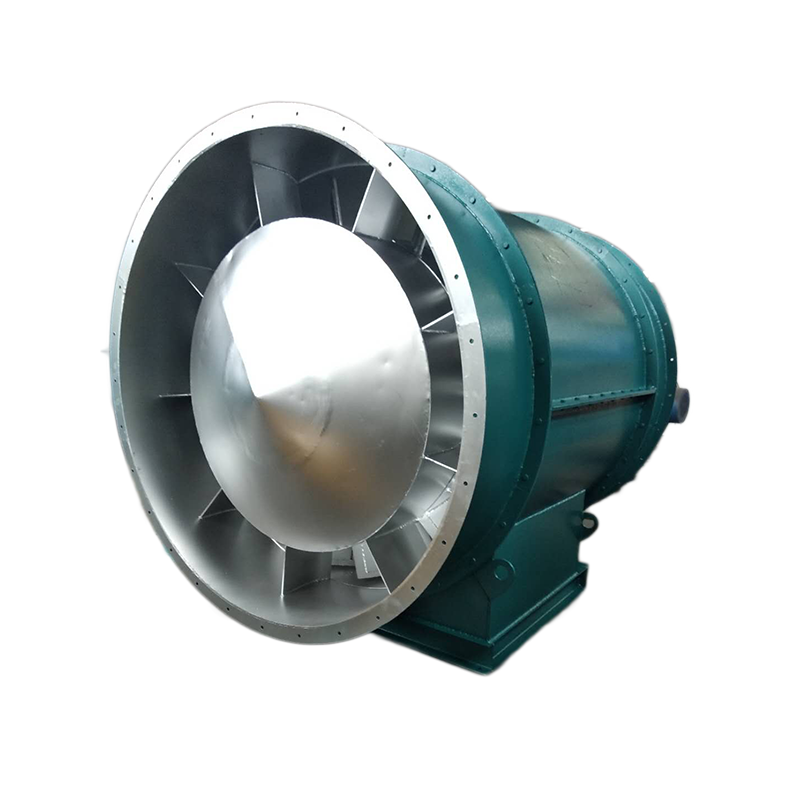

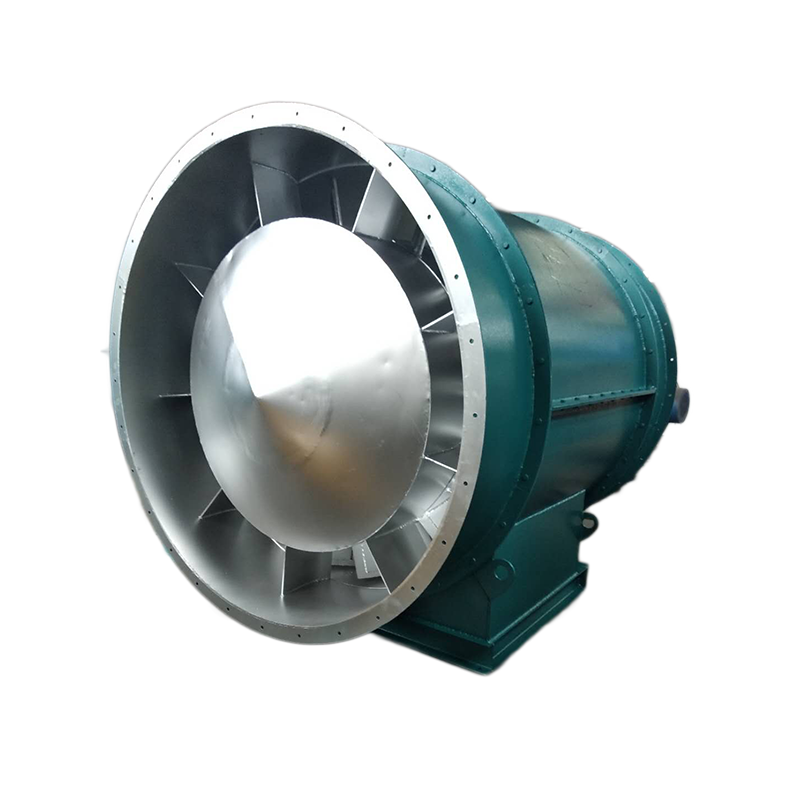

major FRP fan Fans can be divided into axial flow fans, centrifugal fans and diagonal flow (mixed flow) fans according to the flow direction after the airflow enters the impeller. Fans are divided into press in local fans (hereinafter referred to as press in fans) and flame-proof motors placed outside or inside the flow channel, and flame-proof motors placed inside the explosion-proof sealing chamber of the extraction type local fans (hereinafter referred to as extraction fans) according to their purposes. FRP fan company Fans can also be divided into single-stage, two-stage or multi-stage pressurization fans according to the form of pressurization. For example, 4-72 is single-stage pressurization, and high-end fan is multi-stage pressurization fan. Fans can be divided into axial flow fans, mixed flow fans, roof fans, air conditioning fans, etc. Fan can be divided into negative pressure fan, low pressure fan, medium pressure fan and high pressure fan according to pressure. According to the outlet pressure (pressure rise), it can be divided into: ventilator (≤ 15000 Pa), blower (15-350000 Pa), compressor (≥ 350000 Pa)

3. When installing Type C and Type B, ensure that the two pulley positions are on the same plane, and the flatness tolerance is 0.5mm. 4. When installing Type D, use a dial indicator and feeler gauge to measure the coaxiality of the fan spindle and motor spindle and the parallelism of both ends of the coupling. The coaxiality tolerance of two shafts is 0.2mm, the parallelism tolerance of both ends of the coupling is 0.2mm, and the spacing between two planes of the coupling is 5 to 8mm. 5. After the fan is installed, move the rotor with hand or lever to check whether it is too tight or collided. The test run can be carried out without overtightening or collision. 6. After the motor is installed, the belt pulley or coupling guard shall be installed. If the air inlet is not connected to the air inlet pipe, the guard net or other safety devices (provided by the user) shall also be provided. 7. Other parts shall be installed according to the corresponding positions in the drawing. 8. Add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window.

(2) Precautions for normal operation of fan 1. If the flow is found to be too large, which does not meet the operating requirements, or less flow is required in a short time, the throttling device can be used to adjust to meet the operating requirements. 2. The sensitivity of thermometer and oil pointer shall be checked regularly. 3. In case of any abnormal phenomenon during the start-up, shutdown or operation of the fan, it shall be checked in time. 4. For minor faults found in the inspection, find out the causes in time and try to eliminate or deal with them. If minor faults cannot be eliminated or major faults are found, repair them immediately. 5. In addition to replacing the lubricating oil during each maintenance, the lubricating oil shall also be replaced regularly. Observe the oil level at ordinary times and replenish lubricating oil in time.

Yunnan major FRP fan Forecasts from foreign markets. The member units of China General Machinery Fan Industry Association exported 7969 fans in 2000, with the export delivery value of 81.157 million yuan. From 1991 to 2000, the total number of exported fans was 72876, and the total value of export delivery was 747.26 million yuan. FRP fan company The trend of global economic integration is becoming more and more obvious. The economies of all countries will further depend on each other. International economic cooperation and exchanges will become closer and closer. The international market is at a stage of significant intersection and integration. At the same time, the pace of global industrial restructuring is accelerating, and significant progress has been made in the scale and depth of international division of labor. Developed countries continue to shift industrial production to capital intensive and technology intensive industries, and labor-intensive products are transferred to developing countries and regions. This provides a good development opportunity for China to play its own advantages and enter the international market. Since the 1970s, China has introduced foreign advanced technology of centrifugal compressor, which has improved the product grade through digestion, absorption and innovation. As long as the quality and delivery time are guaranteed and the price advantage is used, it is competitive internationally. Especially after China's entry into WTO, it is entirely possible to increase the fan export. From the historical analysis, the main export varieties are small and medium-sized fans and fan accessories. The main gap between domestic enterprises producing such fans is that the surface quality cannot meet the export requirements. If the appearance quality is improved and the price is favorable, the prospect in the foreign market is broad. From 1991 to 2000, the fan exports of small and medium-sized fans were not stable enough, and there was no obvious growth trend. However, with the continuous progress of technology, it is expected that the export volume of such fans will continue to increase, and it is predicted that the annual average growth rate will be about 5% on the basis of 2000. major FRP fan The export of centrifugal compressors and blowers increased significantly from 1991 to 2000, reaching 870000 sets in 2000. The main exporting countries are India, Pakistan, Iran, Vietnam and other developing countries. It is expected that this trend will continue to develop, reaching 1 million units per year.

The use of wet electrostatic precipitators is becoming more and more common. How much do you know about the equipment? Today, I'm going to popularize knowledge for you and talk about the advantages and disadvantages of wet electrostatic precipitator. Let's learn together. Advantages of electrostatic precipitator High purification efficiency, capable of spreading fine particles of more than 0.01 microns. In the design, different operating parameters can be used to meet the required purification efficiency. ⑵ The resistance loss is small, generally below 20 mm water column. Compared with cyclone dust collector, the total power consumption is small even considering the power consumption of power supply unit and rapping mechanism. ⑶ Yunnan FRP fan The allowable operating temperature is high. For example, the allowable operating temperature of SHWB type circuit dust collector is 250 ℃. Other types can reach 350~400 ℃ or higher. ⑷ Large gas processing range. ⑸ major FRP fan Automatic operation control can be fully realized. Disadvantages of electrostatic precipitator The equipment is relatively complex, requiring a high level of equipment allocation, installation and maintenance management. ⑵ There are certain requirements for the specific resistance of dust, so there is a certain selectivity for dust, which can not make all dust obtain high purification efficiency. ⑶ It is greatly affected by the operating conditions such as air temperature and temperature. If the same kind of dust is operated at different temperatures and humidities, the results will be different. Some dust can work well at a certain temperature and humidities, but the ESP can hardly be used at another temperature and humidities due to the change of dust resistance. ⑷ FRP fan company The primary investment is large, and the horizontal electrostatic precipitator covers a large area. ⑸ At present, the practical effect in some enterprises can not meet the design requirements.