3. When installing Type C and Type B, ensure that the two pulley positions are on the same plane, and the flatness tolerance is 0.5mm. 4. When installing Type D, use a dial indicator and feeler gauge to measure the coaxiality of the fan spindle and motor spindle and the parallelism of both ends of the coupling. The coaxiality tolerance of two shafts is 0.2mm, the parallelism tolerance of both ends of the coupling is 0.2mm, and the spacing between two planes of the coupling is 5 to 8mm. 5. After the fan is installed, move the rotor with hand or lever to check whether it is too tight or collided. The test run can be carried out without overtightening or collision. 6. After the motor is installed, the belt pulley or coupling guard shall be installed. If the air inlet is not connected to the air inlet pipe, the guard net or other safety devices (provided by the user) shall also be provided. 7. Other parts shall be installed according to the corresponding positions in the drawing. 8. Add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window.

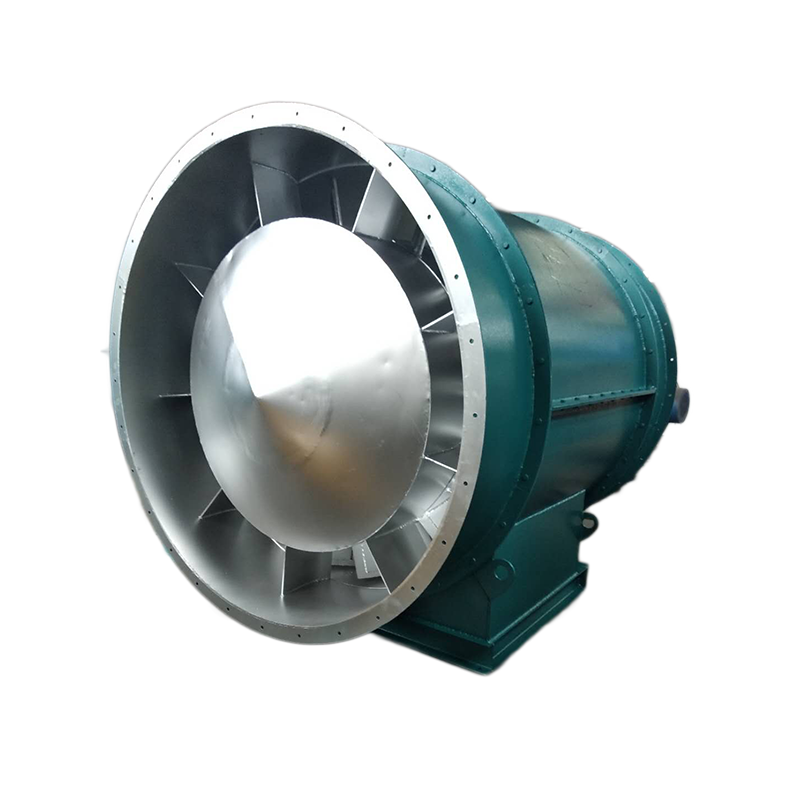

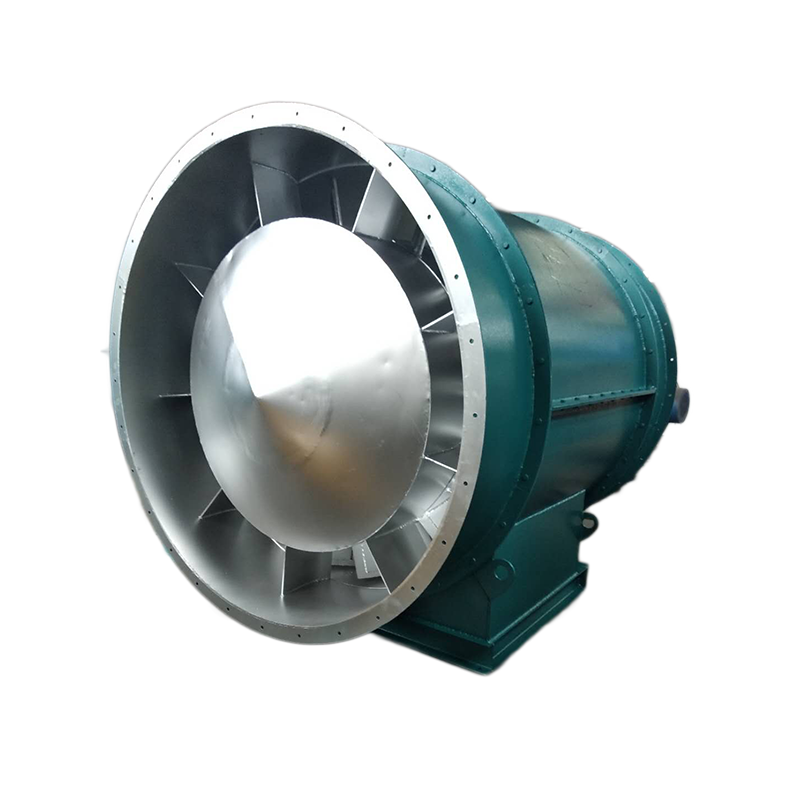

Miluo FRP fan Classified by layers. There are many classification methods for fans, which can be roughly classified according to the following levels: (1) According to the level of pressure generated, they can be divided into: volumetric: reciprocating and rotary; Turbine type: centrifugal, axial flow, mixed flow and cross flow, jet type. Fan generally refers to turbine type, namely centrifugal, axial, mixed flow, cross flow and other forms. Its main characteristics are: centrifugal fan: higher pressure, but smaller air volume. Axial flow fan: higher air volume, but lower pressure. Mixed flow fan: the air volume and pressure are between centrifugal fan and axial fan. Horizontal fan: with high dynamic pressure, it can obtain flat airflow. (2) large FRP fan According to the different materials used, it can be divided into:; Iron shell fan (ordinary fan), glass fiber reinforced plastic fan, plastic fan, aluminum fan, stainless steel fan, etc. (3) According to the direction of gas flow, it can be divided into centrifugal type, axial flow type, diagonal flow type (mixed flow type) and cross flow type. (4) According to the flow direction of the airflow entering the impeller, it can be divided into axial flow fan, centrifugal fan and diagonal flow (mixed flow) fan. (5) FRP fan company It can be divided into: press in local fans and flame-proof motors placed outside or inside the flow channel, and flame-proof motors placed inside the explosion-proof sealing chamber of the extraction type local fans. (6) According to the form of pressurization, it can also be divided into single-stage, two-stage or multi-stage pressurization fans

Main factors affecting the dust removal efficiency of wet electrostatic precipitator. The effect of electrostatic voltage, water volume and dust concentration on wet electrostatic precipitation efficiency is positive, that is, the dust removal efficiency increases with the increase of voltage, water volume and dust concentration. Among them, voltage has the most significant effect on dust removal efficiency, followed by water volume, and dust concentration has the least effect. The combination of static electricity and water mist can significantly improve the dust removal efficiency. The role of water in wet electrostatic precipitation. The water in wet electrostatic precipitator mainly exists as atomized water droplets. According to domestic research, water mist has a series of effects on the improvement of dust removal efficiency of wet electrostatic precipitator, large FRP fan Main mechanism: the water mist can keep the discharge electrode clean and keep the corona vigorous; The mist particles strike the dust collecting electrode to form a thin and uniform water film, Miluo FRP fan It can prevent the "secondary flying" of low specific resistance dust from tempering high specific resistance dust and prevent the occurrence of "reverse corona"; For the dust with strong viscosity, the electrode can be prevented from sticking; It is also suitable for collecting those flammable and explosive dust. The water mist is sprayed directly to the discharge electrode and corona area, and the discharge electrode also acts as an atomizer. The same power supply can realize corona discharge, water atomization, water mist and dust particle charging, realizing the organic combination of static electricity and water mist. The water mist is directly sprayed to the discharge electrode, which has a high charge. The collision interception, adsorption and coagulation of water mist with high charge mass ratio in the electric field can greatly improve the dust removal efficiency. The water mist strikes the dust collecting electrode to form water flow down, so that the dust collecting electrode is always kept clean, eliminating the vibrating device, and avoiding a series of problems caused by vibrating dust removal in dry dust removal. In the method of spraying water mist to the discharge electrode and corona area to further atomize the water mist, the static electricity does not directly contact the spray device, so there is almost no insulation problem. This method is completely different from the dedusting technology of "corona discharge atomizes water". The latter is almost impossible to insulate due to the direct contact between water and electricity, and it is actually difficult to achieve industrial application. The barbed electrode can produce a strong electrostatic field, and has a good corona discharge capacity. The electrostatic and water mist work together, and has a high dust removal efficiency

Main working principles of wet electrostatic precipitator: large FRP fan Spray the water mist to the discharge electrode and corona area, the water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode, and the collision interception, adsorption and coagulation of electric field force and charged water mist will jointly trap the dust particles, and finally the dust particles will reach the dust collector under the drive of electric field force and be trapped. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, Miluo FRP fan First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, FRP fan company Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.

The use of wet electrostatic precipitators is becoming more and more common. How much do you know about the equipment? Today, I'm going to popularize knowledge for you and talk about the advantages and disadvantages of wet electrostatic precipitator. Let's learn together. Advantages of electrostatic precipitator High purification efficiency, capable of spreading fine particles of more than 0.01 microns. In the design, different operating parameters can be used to meet the required purification efficiency. ⑵ The resistance loss is small, generally below 20 mm water column. Compared with cyclone dust collector, the total power consumption is small even considering the power consumption of power supply unit and rapping mechanism. ⑶ Miluo FRP fan The allowable operating temperature is high. For example, the allowable operating temperature of SHWB type circuit dust collector is 250 ℃. Other types can reach 350~400 ℃ or higher. ⑷ Large gas processing range. ⑸ large FRP fan Automatic operation control can be fully realized. Disadvantages of electrostatic precipitator The equipment is relatively complex, requiring a high level of equipment allocation, installation and maintenance management. ⑵ There are certain requirements for the specific resistance of dust, so there is a certain selectivity for dust, which can not make all dust obtain high purification efficiency. ⑶ It is greatly affected by the operating conditions such as air temperature and temperature. If the same kind of dust is operated at different temperatures and humidities, the results will be different. Some dust can work well at a certain temperature and humidities, but the ESP can hardly be used at another temperature and humidities due to the change of dust resistance. ⑷ FRP fan company The primary investment is large, and the horizontal electrostatic precipitator covers a large area. ⑸ At present, the practical effect in some enterprises can not meet the design requirements.

(1) FRP fan company The operating environment should always be kept clean, the fan surface should be kept clean, and the air inlet and outlet should be free of sundries. Regularly remove dust and other sundries in the fan and pipe. (2) large FRP fan It can only be operated when the fan is completely normal. At the same time, it is necessary to maintain sufficient capacity of power supply facilities and stable voltage. Open phase operation is strictly prohibited. The power supply lines must be dedicated lines, and temporary lines should not be used for long-term power supply. (3) In case of abnormal sound, serious heating of motor, electrification of shell, tripping of switch, failure to start and other phenomena of fan during operation, the fan shall be stopped immediately for inspection. To ensure safety, maintenance is not allowed during the operation of the fan. After the maintenance, the test run shall be carried out for about five minutes, and the machine shall be restarted after confirming that there is no abnormal phenomenon. (4) Miluo FRP fan company Replenish or replace lubricating grease for bearings irregularly according to the service environmental conditions (it is not necessary to replace lubricating grease for motor enclosed bearings within the service life). To ensure good lubrication of the fan during operation, the number of times of oiling shall not be less than 1000 hours/time. For enclosed bearings and motor bearings, fill 2/3 of the inner and outer rings of bearings with ZL-3 lithium based lubricating grease. It is strictly prohibited to run without oil. (5) The fan shall be stored in a dry environment to prevent the motor from moisture. Rain proof measures shall be taken when the fan is stored in the open air. The fan shall be prevented from collision during storage and handling to avoid damage to the fan.