Nanchang large Dust removal equipment Installation requirements a. The foundation of the fan shall be level and solid, and the foundation height shall be ≥ 200mm. b、 The fan and air duct shall be connected by flexible hose (flexible material and non combustible), the length shall not be less than 200mm, and the pipe diameter shall be the same as the inlet and outlet size of the fan. In order to ensure that the hose will not be twisted or deformed during the system operation, it should be installed with appropriate tightness. The canvas hose installed at the suction end of the fan can be slightly tightened to prevent the fan from being sucked in during operation and reduce the sectional size of the canvas hose. c、 Dust removal equipment company The steel support of the fan must be fixed on the concrete foundation, and a rubber damping pad must be added between the steel support of the fan and the foundation. All fan and motor components are installed on the whole steel support, and the steel ground frame is installed on the damping pad at the top of the foundation. The damping pad is preferably made of perforated rubber plates. d、 The pipe diameter at the outlet of the fan can only be increased, but not decreased. At the end of the outlet, an insect screen should be installed. When the fan is inclined to the upper outlet, a rain cap should be added

The key points of factors to be considered in the technical approach to the transformation of wet electrostatic precipitators: the wet electrostatic precipitators built before the mid-1970s could not meet the requirements of the new emission standards because of the low requirements for boiler smoke and dust emissions, the small selection of equipment capacity, the outdated structure of electrostatic precipitators, aging of dust removal equipment, low dust removal efficiency and other reasons, These electrostatic precipitators have a problem of transformation to further improve efficiency. large Dust removal equipment company The improvement measures for the original equipment should be considered from both technical and economic aspects, and the following technical approaches are generally adopted: 1. Discover the potential of electrostatic precipitator equipment. For example, adjust the rapping cycle and rapping force of the electrode to improve the corona power and reduce the re flying of dust; Improve the uneven distribution of flue gas velocity and readjust the technical parameters of the airflow distribution device; Adjust the control mode or power supply mode of the power supply equipment. 2、 large Dust removal equipment Combination with other dedusting equipment. That is, a primary precipitator is added before or after the electrostatic precipitator. 3. Increase the capacity (or dust collection area) of the electrostatic precipitator. That is, add an electric field, or increase or widen the electric field of the electrostatic precipitator.

The wet electrostatic precipitator has been recognized by users due to many advantages in the process of application. It can remove dust and purify waste gas. It is an environmental protection equipment that can be used in a wide range of situations. What steps can we take when using this environmental protection equipment? today Dust removal equipment company Let's take a detailed look. 1. First, close the power switch of the wet electrostatic precipitator. When the power indicator is on, the local remote switch will be switched to the local position; 2. Press the fan start button, and then observe whether the fan of the wet electrostatic precipitator rotates correctly. After the fan rotates normally, normal dedusting operation can be started; 3、 large Dust removal equipment After a period of time, if you need to clear and discharge the ash, you can press the ash cleaning button on the wet electrostatic precipitator; 4. Turn over the pulse valve to clear the ash, and the screw machine and ash discharge valve will also work together. The above is the whole content of the application process of the wet electrostatic precipitator. What we need to remind us here is that the equipment can be started only after the position is adjusted before it is used. During the dust removal process of the equipment, the humidification function can be started to keep the ground wet, so that the wet electrostatic precipitator can have a better application effect.

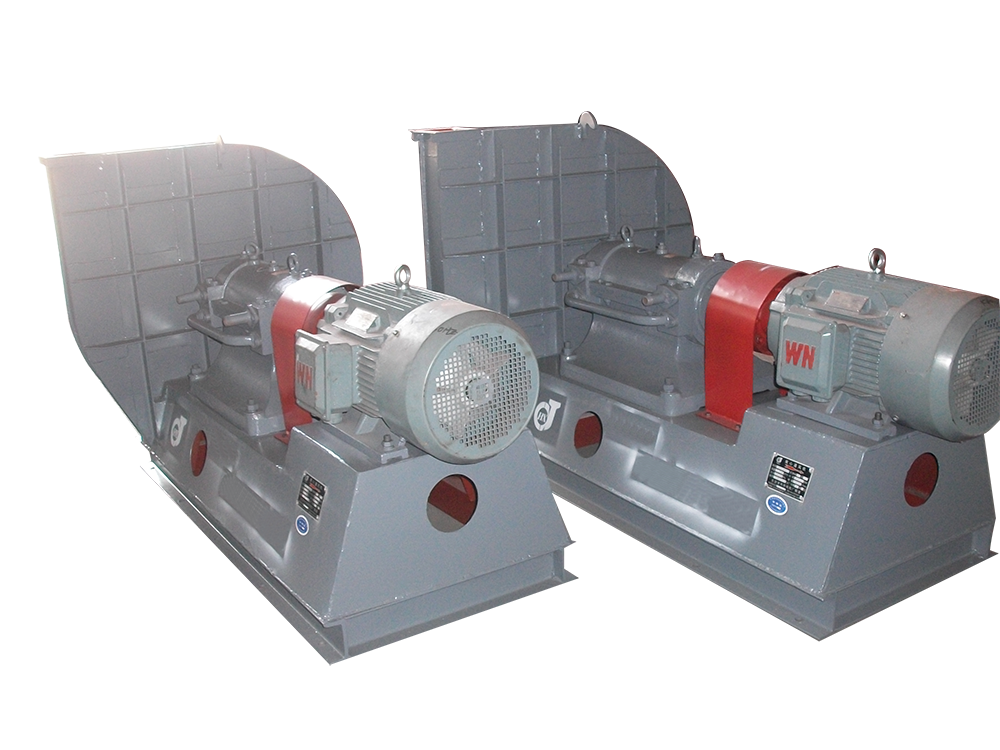

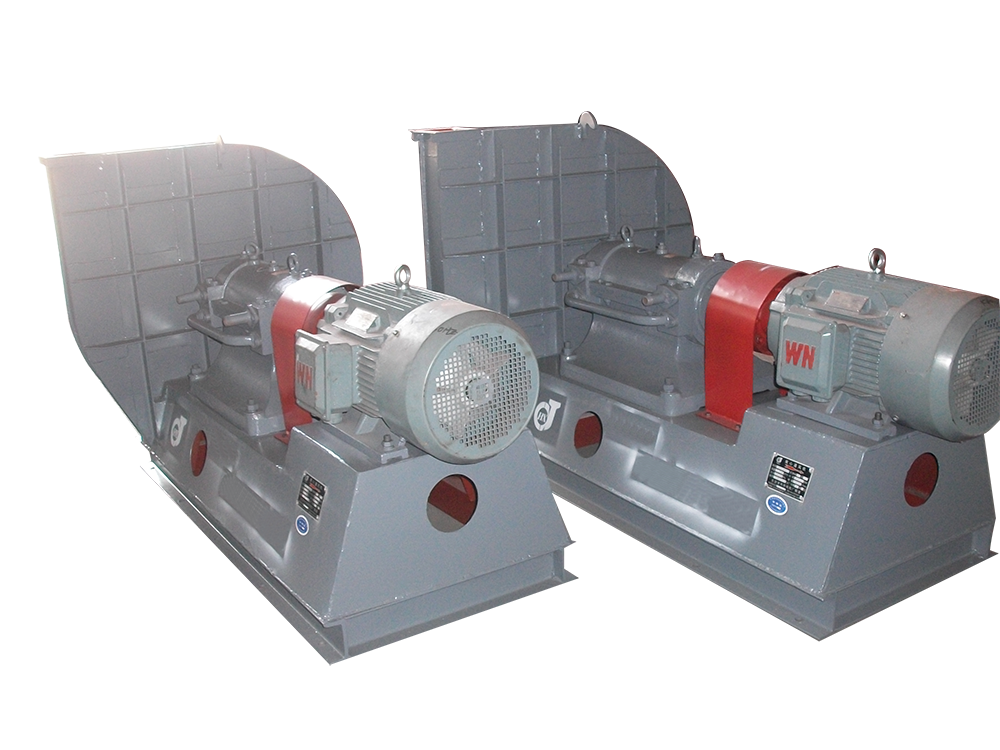

large Dust removal equipment The fan is a kind of driven fluid machinery, which relies on the input mechanical energy to increase the gas pressure and discharge gas. Fan is the abbreviation of Chinese custom for gas compression and gas transmission machinery. Generally speaking, fans include fans, blowers, and wind turbines. Nanchang Dust removal equipment company Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings, as well as ventilation and induced draft of boilers and industrial furnaces; Cooling and ventilation in air conditioning equipment and household appliances; Drying and delivery of grain, wind source of wind tunnel and inflation and propulsion of hovercraft

large Dust removal equipment Common fault: the working medium of the fan in the cement industry often contains a certain amount of homogeneous particles with different sizes and shapes, such as the induced draft fan of the dust removal system and the blower for pneumatic conveying. Because these fans work in the dusty air flow, the dust particles in the air flow will not only wear the fan, but also attach ash on the fan blades, and the wear and ash deposition are uneven. As a result, the balance of the fan rotor is destroyed, which causes the fan vibration and shortens the life of the fan. In serious cases, the fan can not work normally. In particular, the fan blades are most severely worn, Dust removal equipment company It not only destroys the flow characteristics in the fan, but also easily leads to major accidents such as blade fracture and runaway. The wear of transmission parts is also a common problem of fans, including various shafts, rollers, reducers, motors, pumps and other bearing positions, bearing seats, keyways, threads and other parts. The traditional repair welding machine processing method is easy to cause material damage, resulting in deformation or fracture of parts, with greater limitations; Brush plating and spray re machining methods often require outsourcing, which not only requires long repair cycle and high cost, but also can not fundamentally solve the causes of wear (poor impact resistance and yield of metal) because the repair materials are metal materials; Many parts can only be scrapped and replaced, which greatly increases the production cost and inventory of spare parts, leaving the enterprise's good resource advantage idle and wasted

While meeting the new standard, the wet electrostatic precipitator can also control the haze fine particles, sulfur trioxide aerosol droplets, organic pollutants, heavy metal pollutants, etc., which has great social benefits. The air pollutant control mode of SCR+ESP/FF+WFGD+WESP is also a relatively effective way to control pollutants in Shangshan Coal fired Power Plant. Dust removal equipment company Common dust control technologies, among which the dry electrostatic precipitator, the electrostatic fabric composite precipitator and the bag type precipitator are used as the front section dust control technology, cannot guarantee the ultra clean emission of flue gas dust after the desulfurization device, while the wet electrostatic precipitator arranged at the downstream of the wet desulfurization device will be used as a reliable terminal dust control technology. The working principle of wet electrostatic precipitator is similar to that of dry electrostatic precipitator. It is high-voltage corona discharge that charges dust or water mist, and charged particles reach the dust collecting plate under the action of electric field force, large Dust removal equipment However, in terms of the way of dust, the dry electrostatic precipitator uses mechanical vibration, while the wet electrostatic precipitator uses flushing fluid to flush electricity, washing the dust captured on the dust collection plate into the ash hopper and then discharging the wet electrostatic precipitator. The advantages of the wet electrostatic precipitator are: because the mass and heat transfer processes occur simultaneously in the process of gas and liquid contact, this type of precipitator has the function of dust removal, It also has the function of flue gas cooling and absorption of harmful gases. Suitable for high temperature. High temperature, flammable, explosive and harmful gases; Normal operation and high purification efficiency; Dust and gas that can be used for gathering fog and dust; Exhaust volume balance; Simple structure. Low investment, convenient operation and maintenance.