The selection of fans Product performance and fan performance listed in the selection table are based on the performance of delivering air under standard conditions. Therefore, when the use condition is non-standard, the H4-72-12 centrifugal fan must convert the use performance into the performance under standard conditions according to the relationship in the table above, and then select according to the performance and selection table. (3) Treatment of excessive or insufficient flow During use, excessive or insufficient flow often occurs. There are many reasons for this phenomenon. If the flow is high and low during use, it is mainly because the resistance in the pipe network is high and low, or the fan works in a non working area. If it is gradually reduced after a long time during use, it is mainly due to pipe network blockage. After the fan is newly installed, the flow is too large or insufficient during the formal operation. The main reasons for this phenomenon are as follows: 1. The actual value of pipe network resistance is too different from the calculated value. In the general pipe network characteristic equation, H=KQ2, if the actual value K of K-resistance coefficient is less than the calculated value K, the flow will increase; If the actual value K is greater than the calculated value K, the flow decreases. See (b) below.

In order to avoid man-made faults and accidents caused by improper maintenance, prevent the occurrence of natural faults and accidents of fans and motors in all aspects, so as to give full play to the efficiency of equipment and extend the service life of equipment, therefore, the maintenance of fans must be strengthened. (1) Working system of fan maintenance The fan maintenance personnel must pay attention to the following points: 1. The fan can only be operated when the fan equipment is completely normal. 2. If the fan equipment starts after maintenance, pay attention to whether all parts of the fan are normal. 3. Regularly clean the dust, dirt, water and other impurities inside the fan and gas transmission pipeline, and check whether the impeller is worn and rusted, if any, repair and replace it in time. 4. Regularly replace the lubricating oil (recommended 3-6 months). It is recommended to add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window. 5. Check the coupling and belt pulley regularly (3-6 months is recommended), and repair and replace them immediately if parts are worn or rusted. 6. The equipment shall not be repaired during operation.

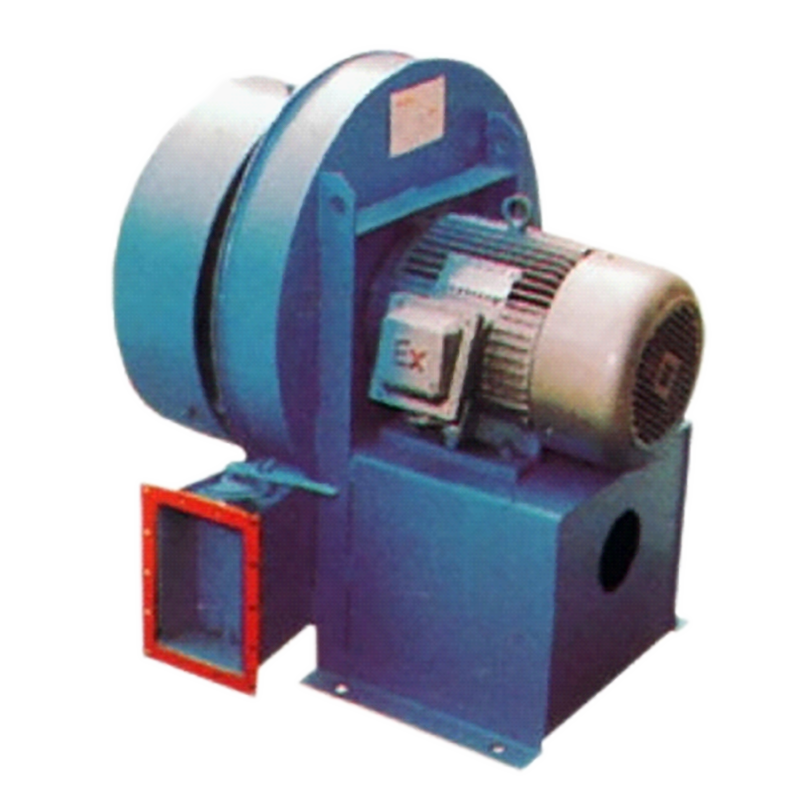

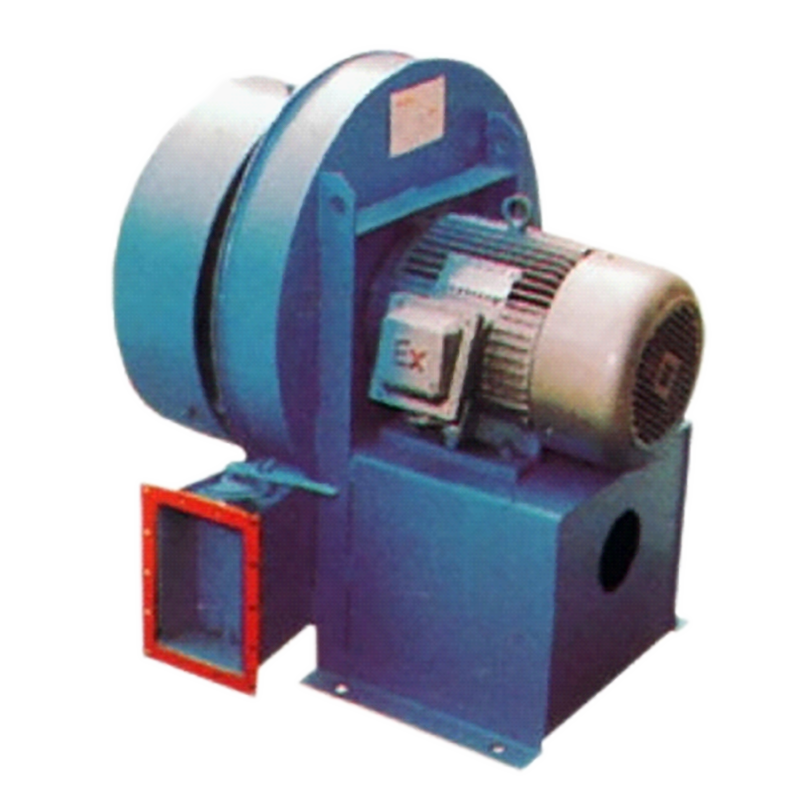

Furnace fan manufactor The work starts before the fan is used. one Yiyang Furnace fan manufactor Carefully read the fan operation instructions and product samples, and be familiar with and understand the fan specifications, forms, impeller rotation direction and air flow in and out direction; Check whether all parts of the fan are in good condition again, or they can be installed and used only after being repaired. 2. The fan must be installed with safety devices to prevent accidents, and installed and wired by professionals familiar with relevant safety requirements. 3. The air duct connecting the inlet and outlet of the fan has separate support, and it is not allowed to add the overlapping weight of the duct to the components of the fan; When installing the fan, pay attention to the horizontal position of the fan, and adjust the connection between the joint surface of the fan and the foundation and the air outlet pipe to make it coincide naturally. Forced connection is not allowed. four large Furnace fan After the fan is installed, move the impeller by hand or lever to check whether it is too tight or rubbed, and whether there is any object that hinders the rotation. The test run can be carried out only when there is no abnormal phenomenon. The exposed part of the fan transmission device should be equipped with a protective cover (provided by the user). If the fan inlet is not connected, a protective screen or other installation device (provided by the user) should also be added. 5. The power distribution control box of the fan must match the corresponding fan (power, voltage, pneumatic mode, control mode, etc.). 6. The fan wiring should be made by a professional electrician, and the wiring must be correct and reliable. Especially, the wiring number at the electric control box should be consistent with the number on the fan terminal. The fan shell should be reliably grounded. The grounding must be reliable, and zero connection cannot be used instead of grounding. 7. After all fans are installed, check whether there are any left tool box sundries inside the fan

Forecast the demand structure from the main fields. large Furnace fan General ventilation fans (generally small and medium-sized centrifugal and axial fans) are the most widely used, with the largest demand and the largest number of manufacturers. In general, the supply of such products exceeds the demand. Although the demand for special purpose fans (including anti-corrosion fans, high-temperature fans, wear-resistant fans, fire smoke exhaust fans, etc.) is not large, due to the special operating environment, they need to be treated differently, because the main material requirements are special. The biggest feature of Roots blower is that when the pressure is adjusted within the allowable range, the flow changes little, the pressure selection range is wide, and it has the characteristics of forced gas transmission. The main disadvantage is that the noise is large. Furnace fan manufactor Through technology introduction, joint venture and self-development, China has launched a three blade roots blower with low noise, which is very popular with users and has a good market prospect. Turbine compressor (including centrifugal compressor, axial compressor and axial centrifugal compound compressor) is an important equipment of major engineering complete equipment, which plays an important role in the national economy. The performance of turbine compressor requires high pressure and large flow. With the large-scale of the complete set of equipment, the turbine compressor parameters are required to be higher and higher. Such as blast furnace smelting plant, large coal chemical plant, large fertilizer plant, large ethylene plant, large air separation plant, natural gas pipeline transportation plant and oil field gas injection plant. The demand for such products accounts for a small proportion of the total fan volume, but because of their importance, complex structure, long manufacturing cycle and high technical content, they have relatively good economic and social benefits. Turbine compressor manufacturing level represents the overall level of the fan industry