The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Jiujiang large Industrial dust collector Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Industrial dust collector company Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.

While meeting the new standard, the wet electrostatic precipitator can also control the haze fine particles, sulfur trioxide aerosol droplets, organic pollutants, heavy metal pollutants, etc., which has great social benefits. The air pollutant control mode of SCR+ESP/FF+WFGD+WESP is also a relatively effective way to control pollutants in Shangshan Coal fired Power Plant. Industrial dust collector company Common dust control technologies, among which the dry electrostatic precipitator, the electrostatic fabric composite precipitator and the bag type precipitator are used as the front section dust control technology, cannot guarantee the ultra clean emission of flue gas dust after the desulfurization device, while the wet electrostatic precipitator arranged at the downstream of the wet desulfurization device will be used as a reliable terminal dust control technology. The working principle of wet electrostatic precipitator is similar to that of dry electrostatic precipitator. It is high-voltage corona discharge that charges dust or water mist, and charged particles reach the dust collecting plate under the action of electric field force, large Industrial dust collector However, in terms of the way of dust, the dry electrostatic precipitator uses mechanical vibration, while the wet electrostatic precipitator uses flushing fluid to flush electricity, washing the dust captured on the dust collection plate into the ash hopper and then discharging the wet electrostatic precipitator. The advantages of the wet electrostatic precipitator are: because the mass and heat transfer processes occur simultaneously in the process of gas and liquid contact, this type of precipitator has the function of dust removal, It also has the function of flue gas cooling and absorption of harmful gases. Suitable for high temperature. High temperature, flammable, explosive and harmful gases; Normal operation and high purification efficiency; Dust and gas that can be used for gathering fog and dust; Exhaust volume balance; Simple structure. Low investment, convenient operation and maintenance.

3. When installing Type C and Type B, ensure that the two pulley positions are on the same plane, and the flatness tolerance is 0.5mm. 4. When installing Type D, use a dial indicator and feeler gauge to measure the coaxiality of the fan spindle and motor spindle and the parallelism of both ends of the coupling. The coaxiality tolerance of two shafts is 0.2mm, the parallelism tolerance of both ends of the coupling is 0.2mm, and the spacing between two planes of the coupling is 5 to 8mm. 5. After the fan is installed, move the rotor with hand or lever to check whether it is too tight or collided. The test run can be carried out without overtightening or collision. 6. After the motor is installed, the belt pulley or coupling guard shall be installed. If the air inlet is not connected to the air inlet pipe, the guard net or other safety devices (provided by the user) shall also be provided. 7. Other parts shall be installed according to the corresponding positions in the drawing. 8. Add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window.

The use of wet electrostatic precipitators is becoming more and more common. How much do you know about the equipment? Today, I'm going to popularize knowledge for you and talk about the advantages and disadvantages of wet electrostatic precipitator. Let's learn together. Advantages of electrostatic precipitator High purification efficiency, capable of spreading fine particles of more than 0.01 microns. In the design, different operating parameters can be used to meet the required purification efficiency. ⑵ The resistance loss is small, generally below 20 mm water column. Compared with cyclone dust collector, the total power consumption is small even considering the power consumption of power supply unit and rapping mechanism. ⑶ Jiujiang Industrial dust collector The allowable operating temperature is high. For example, the allowable operating temperature of SHWB type circuit dust collector is 250 ℃. Other types can reach 350~400 ℃ or higher. ⑷ Large gas processing range. ⑸ large Industrial dust collector Automatic operation control can be fully realized. Disadvantages of electrostatic precipitator The equipment is relatively complex, requiring a high level of equipment allocation, installation and maintenance management. ⑵ There are certain requirements for the specific resistance of dust, so there is a certain selectivity for dust, which can not make all dust obtain high purification efficiency. ⑶ It is greatly affected by the operating conditions such as air temperature and temperature. If the same kind of dust is operated at different temperatures and humidities, the results will be different. Some dust can work well at a certain temperature and humidities, but the ESP can hardly be used at another temperature and humidities due to the change of dust resistance. ⑷ Industrial dust collector company The primary investment is large, and the horizontal electrostatic precipitator covers a large area. ⑸ At present, the practical effect in some enterprises can not meet the design requirements.

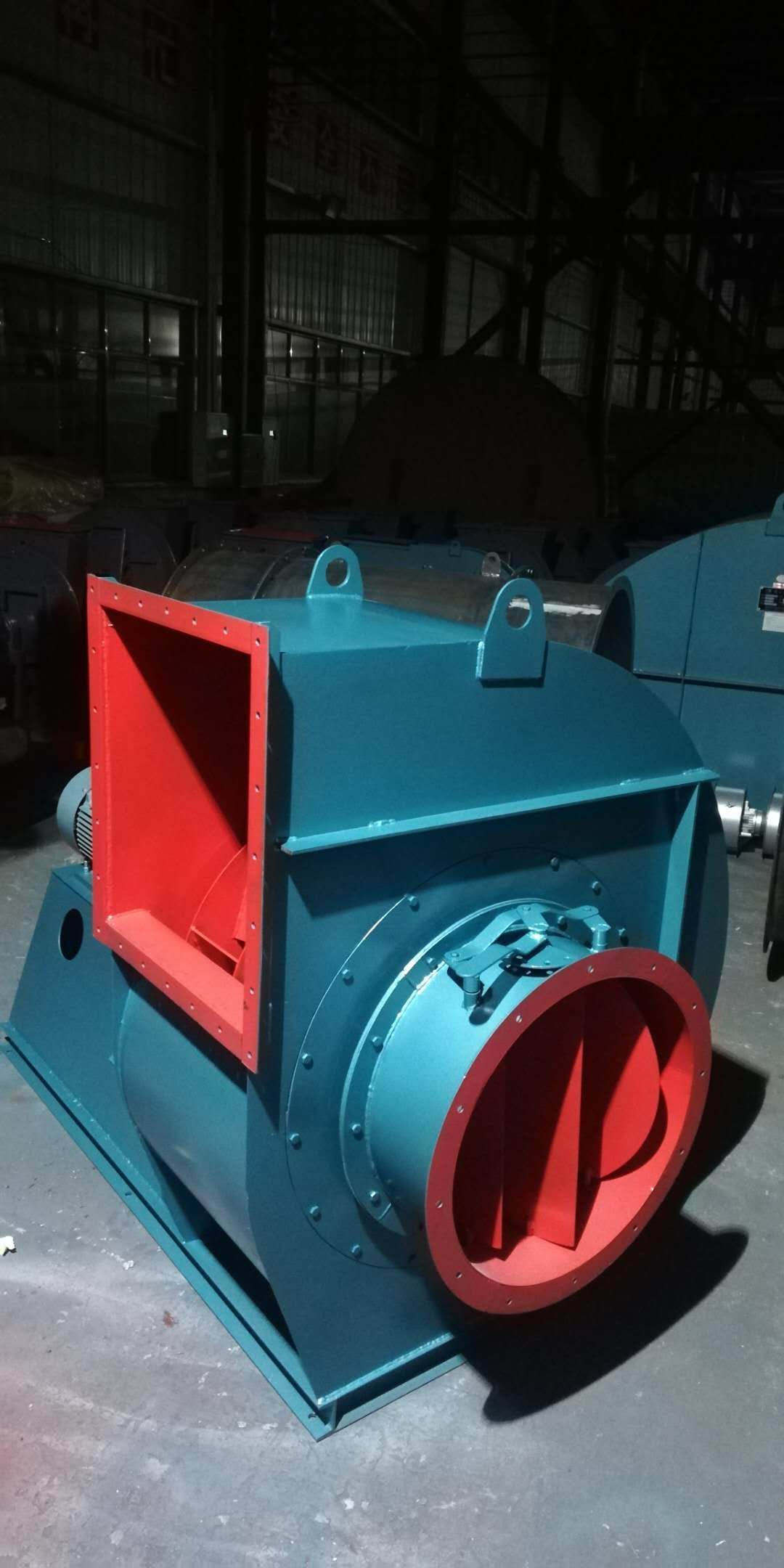

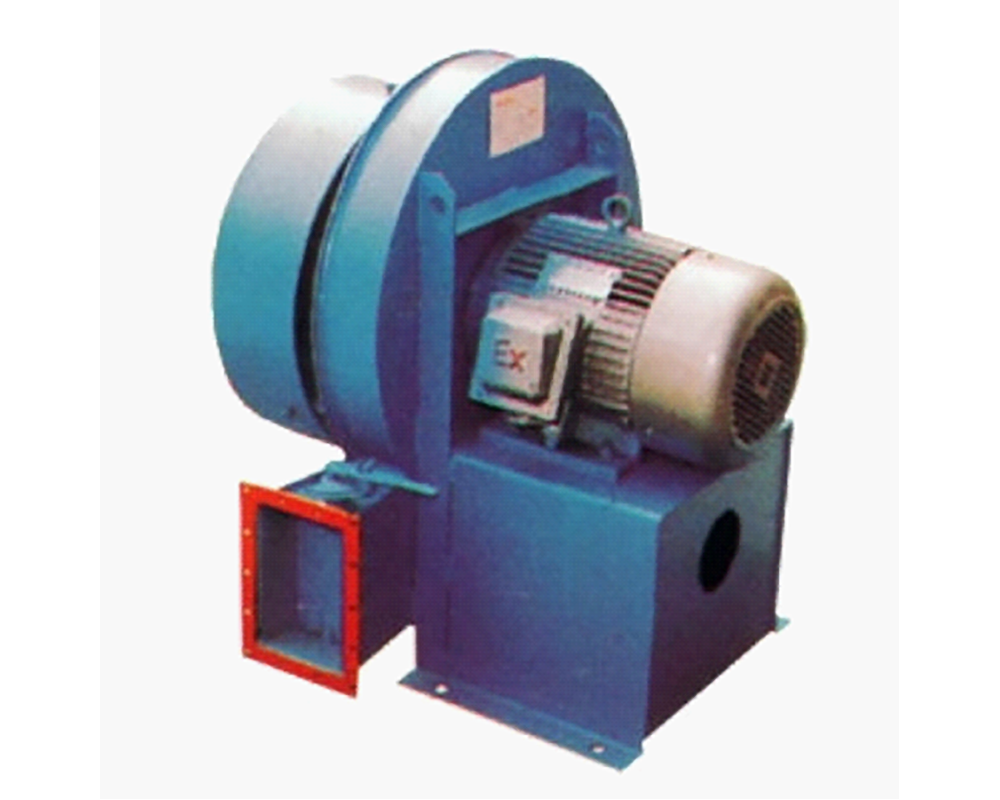

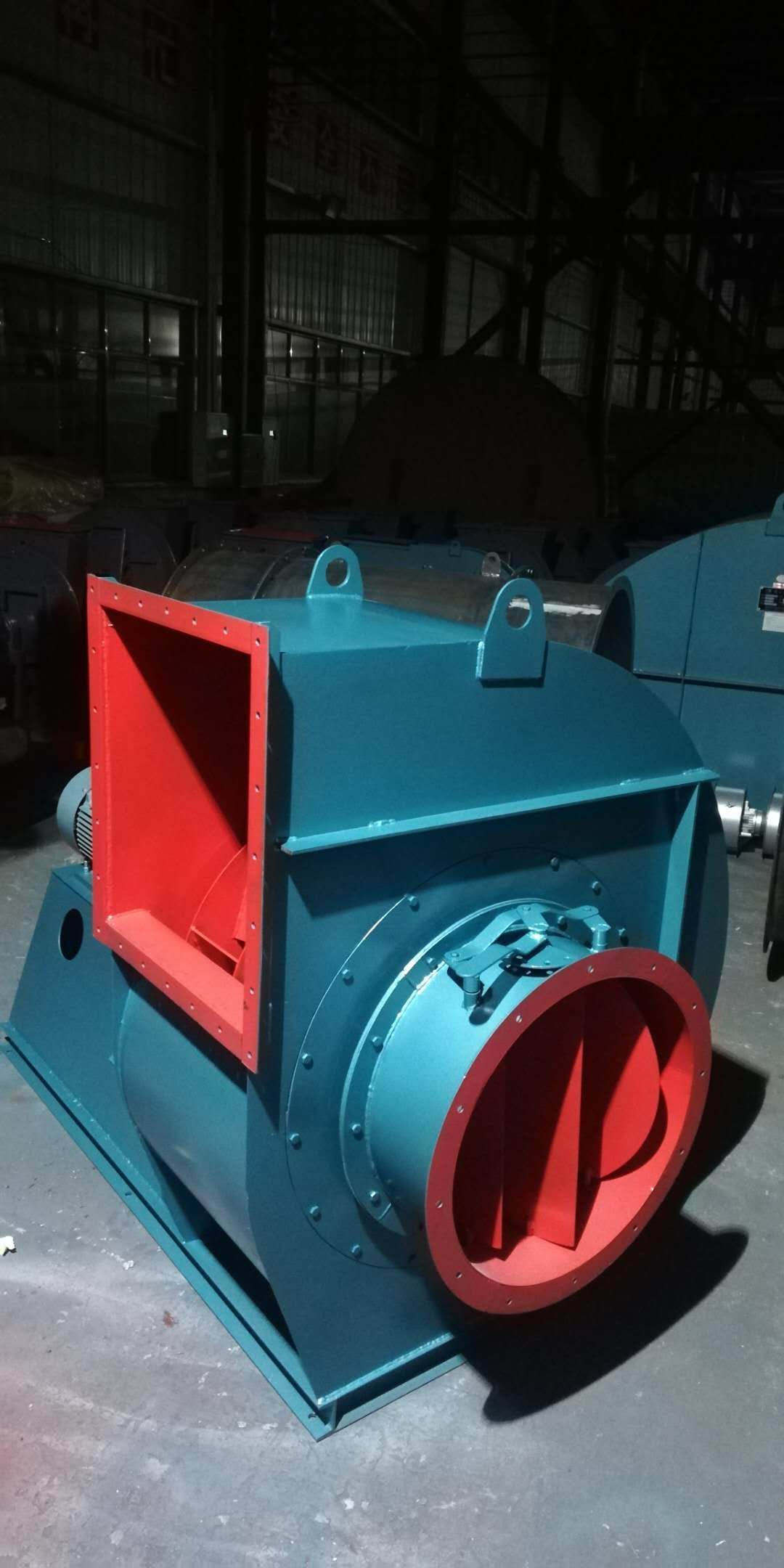

Gas compression and gas transmission machinery is a machine that converts rotating mechanical energy into gas pressure energy and kinetic energy and transports gas. The main structural components of the fan are impeller, casing, air inlet, support, motor, pulley, coupling, silencer, transmission parts (bearings), etc. large Industrial dust collector The unpowered fan uses the air thermal convection caused by the natural wind force and the indoor and outdoor temperature difference to drive the turbine to rotate, thus using the centrifugal force and negative pressure effect to exhaust the indoor stale hot air. Jiujiang Industrial dust collector company The fan is related to the transmission and distribution energy consumption of the system, and is a very critical part of building energy conservation. According to the fan inspection conducted by the National Air Conditioning Equipment Quality Supervision and Inspection Center for many years, many fans have problems under rated conditions, so it is necessary to produce and manufacture fans in strict accordance with product standards. large Industrial dust collector At the beginning of the fan operation, the vibration of the bearing is very small, but with the extension of the operating time, the dust in the fan will be unevenly attached to the impeller, gradually destroying the dynamic balance of the fan, making the bearing vibration gradually increase. Once the vibration reaches the maximum allowable value of 11mm/s of the fan (the maximum allowable value expressed by the amplitude value is as follows), The fan must be shut down for repair (dust accumulation shall be removed and dynamic balance shall be redone). Because it is very dangerous at this time, users must not use it forcibly. When the fan vibration is close to the dangerous value, the vibration measuring instrument will give an alarm.

Jiujiang large Industrial dust collector Forecasts from foreign markets. The member units of China General Machinery Fan Industry Association exported 7969 fans in 2000, with the export delivery value of 81.157 million yuan. From 1991 to 2000, the total number of exported fans was 72876, and the total value of export delivery was 747.26 million yuan. Industrial dust collector company The trend of global economic integration is becoming more and more obvious. The economies of all countries will further depend on each other. International economic cooperation and exchanges will become closer and closer. The international market is at a stage of significant intersection and integration. At the same time, the pace of global industrial restructuring is accelerating, and significant progress has been made in the scale and depth of international division of labor. Developed countries continue to shift industrial production to capital intensive and technology intensive industries, and labor-intensive products are transferred to developing countries and regions. This provides a good development opportunity for China to play its own advantages and enter the international market. Since the 1970s, China has introduced foreign advanced technology of centrifugal compressor, which has improved the product grade through digestion, absorption and innovation. As long as the quality and delivery time are guaranteed and the price advantage is used, it is competitive internationally. Especially after China's entry into WTO, it is entirely possible to increase the fan export. From the historical analysis, the main export varieties are small and medium-sized fans and fan accessories. The main gap between domestic enterprises producing such fans is that the surface quality cannot meet the export requirements. If the appearance quality is improved and the price is favorable, the prospect in the foreign market is broad. From 1991 to 2000, the fan exports of small and medium-sized fans were not stable enough, and there was no obvious growth trend. However, with the continuous progress of technology, it is expected that the export volume of such fans will continue to increase, and it is predicted that the annual average growth rate will be about 5% on the basis of 2000. large Industrial dust collector The export of centrifugal compressors and blowers increased significantly from 1991 to 2000, reaching 870000 sets in 2000. The main exporting countries are India, Pakistan, Iran, Vietnam and other developing countries. It is expected that this trend will continue to develop, reaching 1 million units per year.