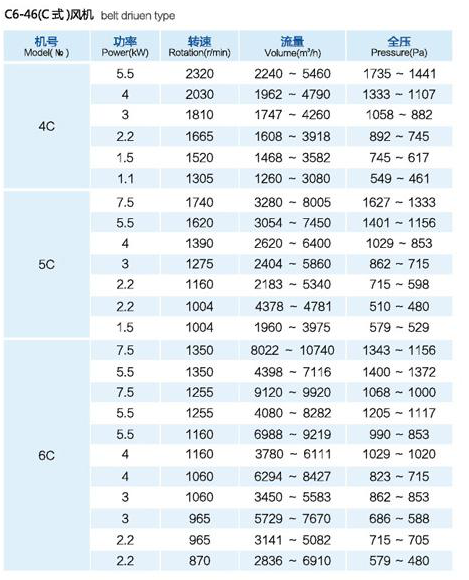

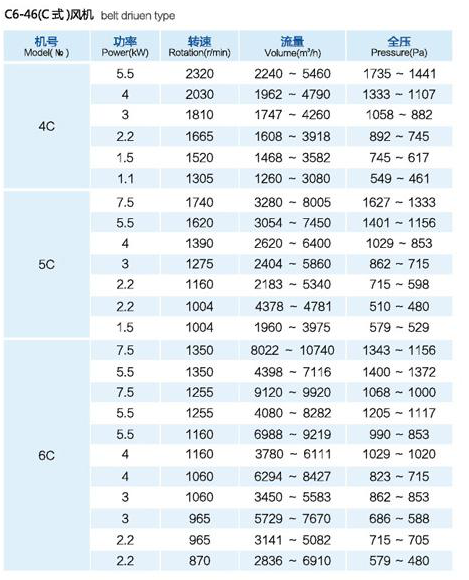

Selection and application of fan performance (I) Description of fan performance: 1. № 10, 12, 16, 20 are converted according to dimensionless performance of № 10 model. 2. № 5, 6, 8 are converted according to dimensionless performance of № 5 model. 3. № 5 and below shall be determined according to the performance of the measured prototype. Note: According to the dimensionless performance curve conversion formula, total pressure H=ρ u2 H (Pa) flow Q=900 π D22 uQ (m3/h) shaft power N=N × D22u3 ρ/4000 (kw), where D2 - impeller outer diameter (m) u - impeller outer edge linear speed (m/s) ρ - gas density (Kg/m3), the required power rate shall be based on shaft power plus mechanical loss and motor reserve. 4. The solid line is № 5 model, and the dotted line is № 10 model. The performance of the fan is expressed by the flow, total pressure, main shaft speed, shaft power, efficiency and other parameters of the fan, and there are certain relationships between the parameters, which are listed in the following table. The relationship of fan performance parameters changes density ρ, speed n changes speed n, atmospheric pressure P, gas temperature t Q1/Q2=n1/n2 H1/H2=(n1/n2) 2 ρ 1/ρ 2 N1/N2=(n1/n2) 3 ρ 1/ρ 2 η 1=η 2 Q1/Q2=n1/n2 H1/H2=(n1/n2) 2 (P1/P2) (273+t2/273+t1) N1/N2=(n1/n2) 3 (P1/P2) (273+t2/273+t1) η 1=η 2 Note: 1. In the middle, Q represents flow (m3/h), H represents total pressure (Pa), N Represents shaft power (kw), η represents total pressure efficiency, ρ represents density (kg/m3), t represents temperature (℃), n represents speed (r/min), and P represents atmospheric pressure (Pa). 2. The footnote symbol 2 indicates the known performance and related parameters, and the footnote symbol 1 indicates the required performance and related parameters. (

The wet electrostatic precipitator is a new kind of dust removal equipment used to treat micro dust and micro particles, customized Wet dedusting equipment It is mainly used to remove dust, acid mist, water droplets, aerosols, odor, PM2.5 and other harmful substances in humid gases, and is an ideal equipment for controlling atmospheric dust pollution. The wet electrostatic precipitator is usually referred to as WESP, which has the same basic principle as the dry electrostatic precipitator. It goes through three stages: charging, collection and dust removal. The principle of wet electrostatic precipitator is the same as that of dry electrostatic precipitator, Yichang Wet dedusting equipment The dust is charged by high-voltage corona discharge, and the charged dust reaches the dust collecting plate/tube under the action of electric field force. The dry electrostatic precipitator mainly deals with dry gas with very low water content, while the wet electrostatic precipitator mainly deals with wet gas with high water content or even saturation. There is a big difference between WESP and DESP in the way of removing the dust collected on the dust collecting plate/pipe. The dry electrostatic precipitator generally uses mechanical rapping or acoustic cleaning to remove the dust on the electrode, while the wet electrostatic precipitator uses regular flushing to remove the dust along with the flow of flushing fluid

The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Yichang customized Wet dedusting equipment Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Wet dedusting equipment manufactor Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.

According to the report data released by the Global Wind Energy Council, the new installed capacity of global wind power in 2014 was 51477MW, up 44% year on year, and the cumulative installed capacity exceeded the threshold of 50GW for the first time. All data set new world records. China's wind power industry has driven global growth. In 2014, China's new installed capacity of wind power was 23350500 kilowatts, 45.1% higher than that of the previous year, customized Wet dedusting equipment The cumulative installed capacity has reached nearly 115 million kilowatts, of which the grid connected capacity is nearly 100 million kilowatts, accounting for 7% of the total installed power generation capacity. In addition to the strength of wind power itself, the recovery of the wind power industry has also contributed to the decline of coal prices. The decline of fuel costs has led to the profitability of most power enterprises hitting a new high in 2014, Wet dedusting equipment manufactor This can expand the scale of wind power construction and accelerate the payment of unit arrears. As a result, the performance of wind power equipment manufacturers was in full swing in 2014, the market concentration was further improved to the top eight complete machine enterprises, and China's wind power industry basically ended the situation of low price competition. The wind power industry generally believes that the wind power industry will enter a new normal of stable growth in the future. In the next five years, the annual new installed capacity may reach at least 20 million kilowatts, and there is still a bottleneck for developers to improve their profits.

Wet dedusting equipment manufactor The work starts before the fan is used. one Yichang Wet dedusting equipment manufactor Carefully read the fan operation instructions and product samples, and be familiar with and understand the fan specifications, forms, impeller rotation direction and air flow in and out direction; Check whether all parts of the fan are in good condition again, or they can be installed and used only after being repaired. 2. The fan must be installed with safety devices to prevent accidents, and installed and wired by professionals familiar with relevant safety requirements. 3. The air duct connecting the inlet and outlet of the fan has separate support, and it is not allowed to add the overlapping weight of the duct to the components of the fan; When installing the fan, pay attention to the horizontal position of the fan, and adjust the connection between the joint surface of the fan and the foundation and the air outlet pipe to make it coincide naturally. Forced connection is not allowed. four customized Wet dedusting equipment After the fan is installed, move the impeller by hand or lever to check whether it is too tight or rubbed, and whether there is any object that hinders the rotation. The test run can be carried out only when there is no abnormal phenomenon. The exposed part of the fan transmission device should be equipped with a protective cover (provided by the user). If the fan inlet is not connected, a protective screen or other installation device (provided by the user) should also be added. 5. The power distribution control box of the fan must match the corresponding fan (power, voltage, pneumatic mode, control mode, etc.). 6. The fan wiring should be made by a professional electrician, and the wiring must be correct and reliable. Especially, the wiring number at the electric control box should be consistent with the number on the fan terminal. The fan shell should be reliably grounded. The grounding must be reliable, and zero connection cannot be used instead of grounding. 7. After all fans are installed, check whether there are any left tool box sundries inside the fan

Wet dedusting equipment manufactor In the use of wet electrostatic precipitator, we will encounter problems of one kind or another. If we do not know how to solve them, we will not know what to do. What are the reasons for the failure of wet electrostatic precipitator? Next, I will analyze it for you. (1) customized Wet dedusting equipment The causes of electrical failure include: electrical components are damaged, corona electrode is not adjusted properly, and porcelain bushing and post insulator through the wall are damaged. ① The electrical components are damaged, such as the fuse is blown, the high-voltage silicon rectifier tube is broken down or the thyristor is damaged, which can lead to the power failure; If the milliammeter is damaged or the transformer fails, the phenomenon of fault type (3) will occur. ② If the nickel chromium alloy wire is not used, the corona electrode will be rusted and broken after being used for a short time. The tension of corona wire is uneven, the force is uneven, and the overload of individual corona electrode will also cause the corona electrode to break; If the corona electrode is not installed in place, deviates from the center of the settling tube, or has too much scale, the electric field will flash over frequently, or even the operation will be interrupted. ③ If the mechanical properties of the through wall porcelain bushing and post insulator are not up to standard and cannot bear the tension of the upper and lower hangers, the insulator will be damaged and cracked. The insulator box temperature control is unreasonable, and the temperature is low or changes violently, which will also cause the insulator to be damaged and cracked; Excessive scale on the surface of insulator will also cause damage and crack of insulator. The final result is that the electric field is grounded, the operation of the electrostatic precipitator is interrupted, and faults (2) and (4) occur.