The wet electrostatic precipitator is a new kind of dust removal equipment used to treat micro dust and micro particles, customized Wet dedusting equipment It is mainly used to remove dust, acid mist, water droplets, aerosols, odor, PM2.5 and other harmful substances in humid gases, and is an ideal equipment for controlling atmospheric dust pollution. The wet electrostatic precipitator is usually referred to as WESP, which has the same basic principle as the dry electrostatic precipitator. It goes through three stages: charging, collection and dust removal. The principle of wet electrostatic precipitator is the same as that of dry electrostatic precipitator, Hunan Wet dedusting equipment The dust is charged by high-voltage corona discharge, and the charged dust reaches the dust collecting plate/tube under the action of electric field force. The dry electrostatic precipitator mainly deals with dry gas with very low water content, while the wet electrostatic precipitator mainly deals with wet gas with high water content or even saturation. There is a big difference between WESP and DESP in the way of removing the dust collected on the dust collecting plate/pipe. The dry electrostatic precipitator generally uses mechanical rapping or acoustic cleaning to remove the dust on the electrode, while the wet electrostatic precipitator uses regular flushing to remove the dust along with the flow of flushing fluid

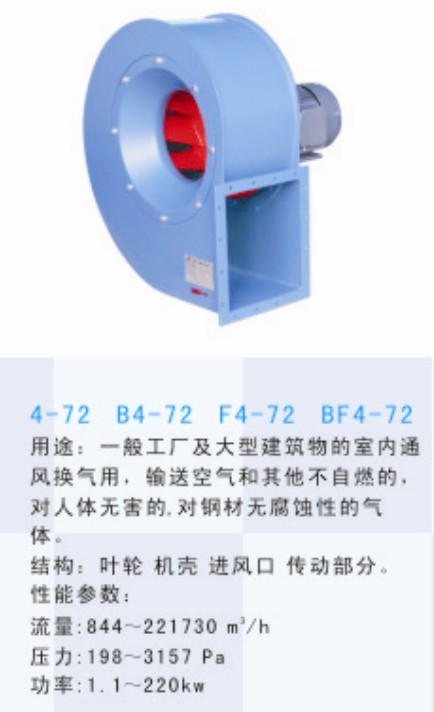

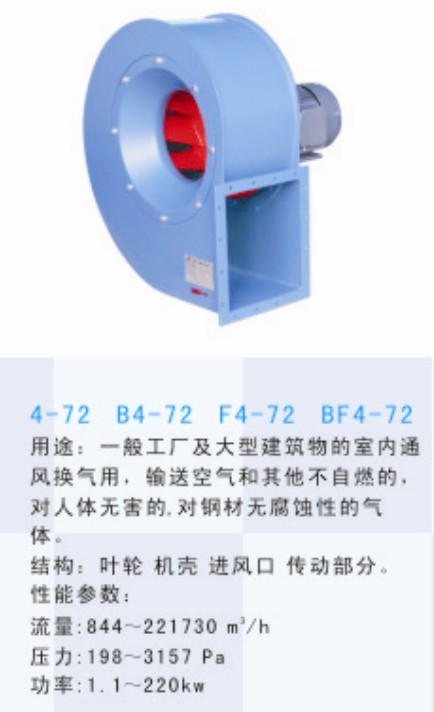

customized Wet dedusting equipment The fan is a kind of driven fluid machinery, which relies on the input mechanical energy to increase the gas pressure and discharge gas. Fan is the abbreviation of Chinese custom for gas compression and gas transmission machinery. Generally speaking, fans include fans, blowers, and wind turbines. Hunan Wet dedusting equipment Price Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings, as well as ventilation and induced draft of boilers and industrial furnaces; Cooling and ventilation in air conditioning equipment and household appliances; Drying and delivery of grain, wind source of wind tunnel and inflation and propulsion of hovercraft

Wet dedusting equipment Price Different types of dust remover equipment have their own precautions. When we usually use the dust remover equipment, we should tell my customer friends some application matters. What matters should we consider when using wet electrostatic precipitator? Matters needing attention on the application of wet electrostatic precipitator. 1. The wet electrostatic precipitator shall be put into the insulator chamber electric heating and hot air purging system at least 8 hours in advance to ensure that the temperature of the insulator chamber is more than 60 ℃. 2. The wet desulfurization system of the wet electrostatic precipitator is put into operation early to prevent dry and high-temperature smoke from entering the wet electrostatic precipitator, which will lead to scaling of internal parts and damage of internal anti-corrosion coating. three customized Wet dedusting equipment The wet dust collector can be opened when the following three conditions are met together: 3.1 The wet electrostatic precipitator is operated with 25% of the oil gun remaining and 35% of the powder feeding is normal and stable or the oil gun is completely withdrawn. 3.2 The temperature of flue gas entering the wet electrostatic precipitator is lower than 70 ℃. 3.3 Desulfurization equipment has been opened. 4. The process of opening the wet electrostatic precipitator: first open the low-pressure water supply system and then the high-pressure power supply system.

The wet electrostatic precipitator is mainly used to purify water vapor, odor, acid mist and other harmful substances in the exhaust gas discharged by the factory. As an air pollution control equipment, it has also been widely used. let's Wet dedusting equipment Price Understand its system composition together. 1. Composition of wet electrostatic precipitator system. According to its working principle, the control system of wet electrostatic precipitator generally includes high pressure system, water treatment system, low pressure heating and hot air purging system, upper computer system, etc. 2. Design of wet electrostatic precipitator system. (1) customized Wet dedusting equipment High voltage system and wet electrostatic precipitator charge the dust through corona discharge of high voltage system. The charged dust reaches the dust collecting plate under the effect of electric field force, and then the dust is removed by regular scouring. (2) Hunan customized Wet dedusting equipment Water treatment system. This system deals with the problem of secondary water pollution. It is mainly the water discharged after equipment spraying and flushing, which contains a lot of acid substances and fine particles. Direct discharge will cause secondary pollution. The recycling of water in the equipment consists of two steps: neutralization and acid removal, and separation of suspended solids, so that the sewage can be turned into industrial water suitable for spraying. (3) Heating system. The heating system includes insulator incubator heating, hot air purging heating, and the hot air purging system is composed of fan, butterfly valve and heater. When it starts actively, it starts in the order of fan, butterfly valve and heater. When actively closing, it shall be closed in reverse order. (4) Upper computer system. The selected upper computer system is an industrial control computer, and the network front-end computer is used to enable the system to have extraordinary data acquisition and processing capabilities, so as to meet the requirements of wet electrostatic precipitator for centralized management, decentralized control, energy conservation and emission reduction.