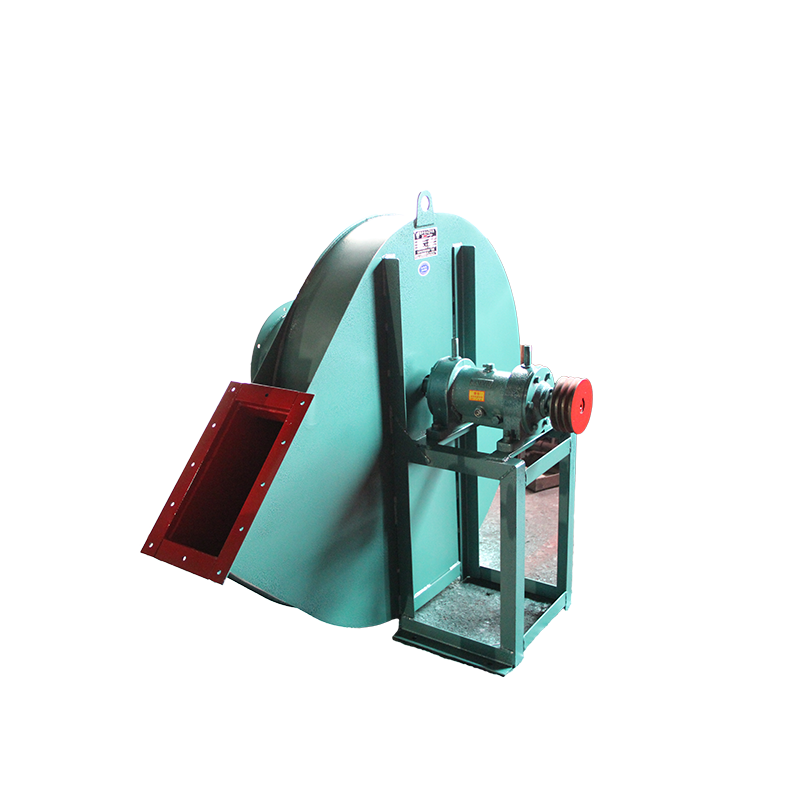

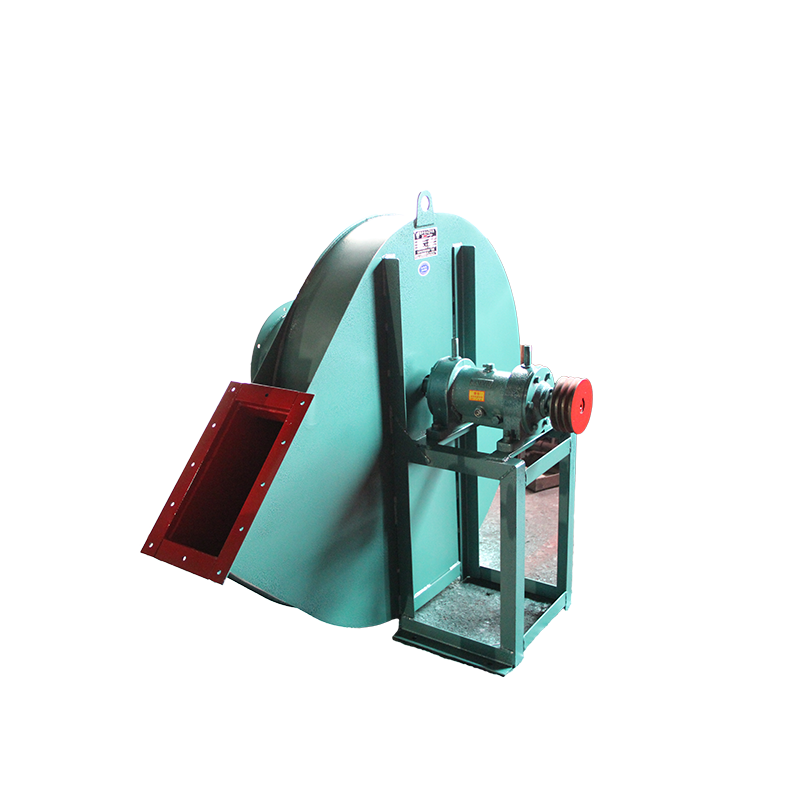

Before installation, first prepare the materials and tools for installation, and check the parts of the fan, especially the impeller, main shaft, bearing and other parts. If any damage is found, repair it, and then clean the inside of the bearing box with kerosene. In the process of installation, the following points must be paid attention to: 1. In order to prevent rust and reduce the difficulty of disassembly, some grease or machine oil should be coated on some joint surfaces. 2. When installing the bolts on the joint surface, if there are positioning pins, install the pins and tighten them before tightening the bolts. 3. Check that there should be no tools and sundries falling or left in the casing and other casings. Installed and used by CHANG factory bridge QIAO ISO9001 quality management system certification enterprise of Beijing No. 2 Blower Works 1. When installing the fan, the inlet and outlet must be provided with soft connection, and the weight of the gas transmission pipeline should not be added to the casing. Correct the gap size between the air inlet and the impeller according to the drawing, and keep the shaft in a horizontal position. 2. When installing the soft connection of the air inlet, the bolts of the air inlet itself can be directly used for connection. At this time, the air inlet is fixed by three countersunk screws.

Chongqing major Wet dedusting equipment Fan performance parameters. The performance parameters of fan mainly include flow, pressure, power, efficiency and speed. In addition, the size of noise and vibration is also the main fan design index. Flow, also known as air volume, is expressed by the volume of gas flowing through the fan in unit time; Pressure, also known as wind pressure, refers to the pressure rise value of gas in the fan, including static pressure, dynamic pressure and total pressure; Power refers to the input power of the fan, namely shaft power. The ratio of effective power of fan to shaft power is called efficiency. Wet dedusting equipment company The total pressure efficiency of fan can reach 90%. Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; Ventilation and induced draft of boiler and industrial furnace; Cooling and ventilation in air conditioning equipment and household appliances; Drying and selection of grain; Wind source of wind tunnel and inflation and propulsion of hovercraft. The working principle of the fan is basically the same as that of the turbine compressor, but because the gas flow rate is low and the pressure changes little, it is generally unnecessary to consider the change of gas specific volume, that is, treat the gas as an incompressible fluid

Emergency stop: major Wet dedusting equipment company In case of one of the following situations during the unit commissioning, emergency shutdown shall be carried out immediately. The emergency stop operation is to press the stop button of the main motor, and then carry out the remedial work after the shutdown; The centrifugal fan suddenly vibrates strongly and has exceeded the trip value; There is scratch or abnormal friction sound inside the machine body; major Wet dedusting equipment Smoke occurs at any bearing or seal, or the temperature of a bearing rises sharply to the alarm value; When the oil pressure is lower than the alarm value and cannot be restored to normal; The liquid level in the oil tank is low, and there is suction phenomenon; When the axial displacement value increases significantly and reaches the alarm value;

Main factors affecting the dust removal efficiency of wet electrostatic precipitator. The effect of electrostatic voltage, water volume and dust concentration on wet electrostatic precipitation efficiency is positive, that is, the dust removal efficiency increases with the increase of voltage, water volume and dust concentration. Among them, voltage has the most significant effect on dust removal efficiency, followed by water volume, and dust concentration has the least effect. The combination of static electricity and water mist can significantly improve the dust removal efficiency. The role of water in wet electrostatic precipitation. The water in wet electrostatic precipitator mainly exists as atomized water droplets. According to domestic research, water mist has a series of effects on the improvement of dust removal efficiency of wet electrostatic precipitator, major Wet dedusting equipment Main mechanism: the water mist can keep the discharge electrode clean and keep the corona vigorous; The mist particles strike the dust collecting electrode to form a thin and uniform water film, Chongqing Wet dedusting equipment It can prevent the "secondary flying" of low specific resistance dust from tempering high specific resistance dust and prevent the occurrence of "reverse corona"; For the dust with strong viscosity, the electrode can be prevented from sticking; It is also suitable for collecting those flammable and explosive dust. The water mist is sprayed directly to the discharge electrode and corona area, and the discharge electrode also acts as an atomizer. The same power supply can realize corona discharge, water atomization, water mist and dust particle charging, realizing the organic combination of static electricity and water mist. The water mist is directly sprayed to the discharge electrode, which has a high charge. The collision interception, adsorption and coagulation of water mist with high charge mass ratio in the electric field can greatly improve the dust removal efficiency. The water mist strikes the dust collecting electrode to form water flow down, so that the dust collecting electrode is always kept clean, eliminating the vibrating device, and avoiding a series of problems caused by vibrating dust removal in dry dust removal. In the method of spraying water mist to the discharge electrode and corona area to further atomize the water mist, the static electricity does not directly contact the spray device, so there is almost no insulation problem. This method is completely different from the dedusting technology of "corona discharge atomizes water". The latter is almost impossible to insulate due to the direct contact between water and electricity, and it is actually difficult to achieve industrial application. The barbed electrode can produce a strong electrostatic field, and has a good corona discharge capacity. The electrostatic and water mist work together, and has a high dust removal efficiency

The wet electrostatic precipitator is mainly used to purify water vapor, odor, acid mist and other harmful substances in the exhaust gas discharged by the factory. As an air pollution control equipment, it has also been widely used. let's Wet dedusting equipment company Understand its system composition together. 1. Composition of wet electrostatic precipitator system. According to its working principle, the control system of wet electrostatic precipitator generally includes high pressure system, water treatment system, low pressure heating and hot air purging system, upper computer system, etc. 2. Design of wet electrostatic precipitator system. (1) major Wet dedusting equipment High voltage system and wet electrostatic precipitator charge the dust through corona discharge of high voltage system. The charged dust reaches the dust collecting plate under the effect of electric field force, and then the dust is removed by regular scouring. (2) Chongqing major Wet dedusting equipment Water treatment system. This system deals with the problem of secondary water pollution. It is mainly the water discharged after equipment spraying and flushing, which contains a lot of acid substances and fine particles. Direct discharge will cause secondary pollution. The recycling of water in the equipment consists of two steps: neutralization and acid removal, and separation of suspended solids, so that the sewage can be turned into industrial water suitable for spraying. (3) Heating system. The heating system includes insulator incubator heating, hot air purging heating, and the hot air purging system is composed of fan, butterfly valve and heater. When it starts actively, it starts in the order of fan, butterfly valve and heater. When actively closing, it shall be closed in reverse order. (4) Upper computer system. The selected upper computer system is an industrial control computer, and the network front-end computer is used to enable the system to have extraordinary data acquisition and processing capabilities, so as to meet the requirements of wet electrostatic precipitator for centralized management, decentralized control, energy conservation and emission reduction.

Main working principles of wet electrostatic precipitator: major Wet dedusting equipment Spray the water mist to the discharge electrode and corona area. The water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode. The collision interception, adsorption and condensation of electric field force and charged water mist will jointly trap the dust particles. Finally, the dust particles will reach the dust collecting electrode and be trapped under the drive of electric field force. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, Chongqing Wet dedusting equipment First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, Wet dedusting equipment company Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.