The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Hezhou major Wet dust collector Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Wet dust collector Price Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.

Among all kinds of mechanical and electrical equipment in all walks of life in China, the motors matched with fans account for about 60% of the installed capacity of national motors, and the power consumption accounts for about one-third of the total power generation in China. In particular, Wet dust collector Price Most fans have the phenomenon of pulling a cart from a horse during use. In addition, due to changes in production and technology, it is necessary to frequently adjust the gas flow, pressure, temperature, etc; Many units still adopt the backward way of adjusting the opening degree of the wind shield or valve to adjust the gas flow, pressure, temperature, etc. In fact, this is to meet the requirements of process and working conditions for gas flow regulation by artificially increasing resistance at the cost of wasting electric energy and money. This backward regulation mode not only wastes valuable energy, but also has poor regulation accuracy, which is difficult to meet the requirements of modern industrial production and services, and has serious negative effects. With the continuous improvement and development of frequency conversion technology in recent ten years. The performance of variable frequency speed regulation is becoming increasingly perfect, major Wet dust collector It has been widely used in AC speed regulation in different fields. It has brought considerable economic benefits to enterprises and promoted the automation process of industrial production.

Wet dust collector Price In the use of wet electrostatic precipitator, we will encounter problems of one kind or another. If we do not know how to solve them, we will not know what to do. What are the reasons for the failure of wet electrostatic precipitator? Next, I will analyze it for you. (1) major Wet dust collector The causes of electrical failure include: electrical components are damaged, corona electrode is not adjusted properly, and porcelain bushing and post insulator through the wall are damaged. ① The electrical components are damaged, such as the fuse is blown, the high-voltage silicon rectifier tube is broken down or the thyristor is damaged, which can lead to the power failure; If the milliammeter is damaged or the transformer fails, the phenomenon of fault type (3) will occur. ② If the nickel chromium alloy wire is not used, the corona electrode will be rusted and broken after being used for a short time. The tension of corona wire is uneven, the force is uneven, and the overload of individual corona electrode will also cause the corona electrode to break; If the corona electrode is not installed in place, deviates from the center of the settling tube, or has too much scale, the electric field will flash over frequently, or even the operation will be interrupted. ③ If the mechanical properties of the through wall porcelain bushing and post insulator are not up to standard and cannot bear the tension of the upper and lower hangers, the insulator will be damaged and cracked. The insulator box temperature control is unreasonable, and the temperature is low or changes violently, which will also cause the insulator to be damaged and cracked; Excessive scale on the surface of insulator will also cause damage and crack of insulator. The final result is that the electric field is grounded, the operation of the electrostatic precipitator is interrupted, and faults (2) and (4) occur.

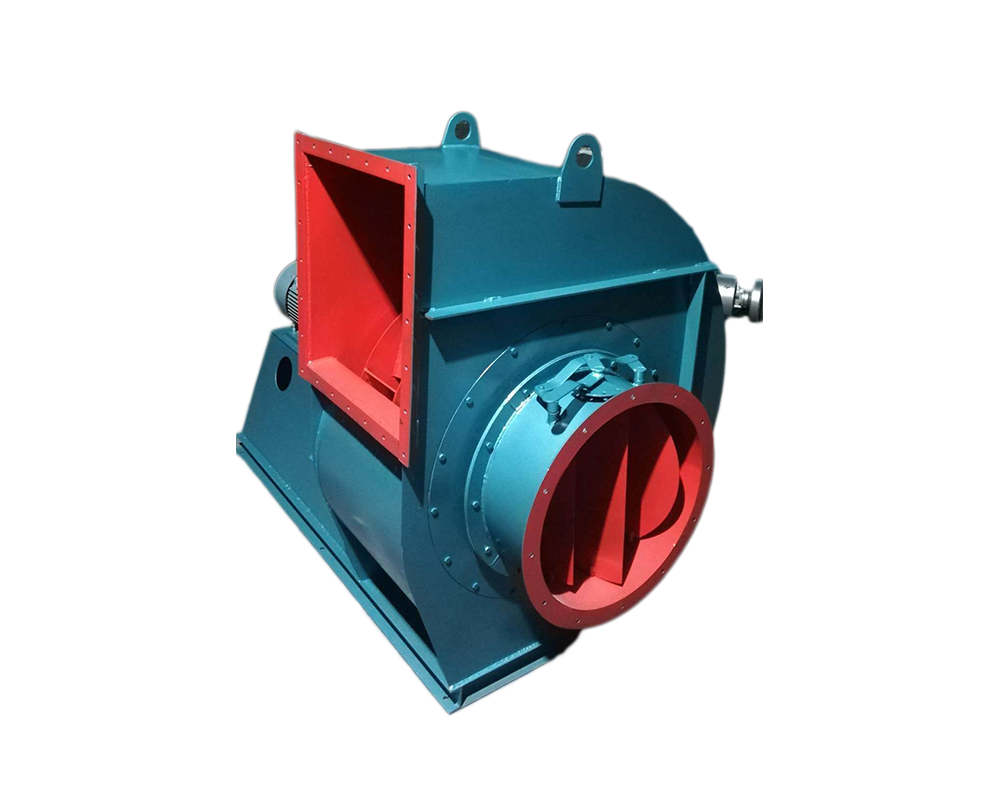

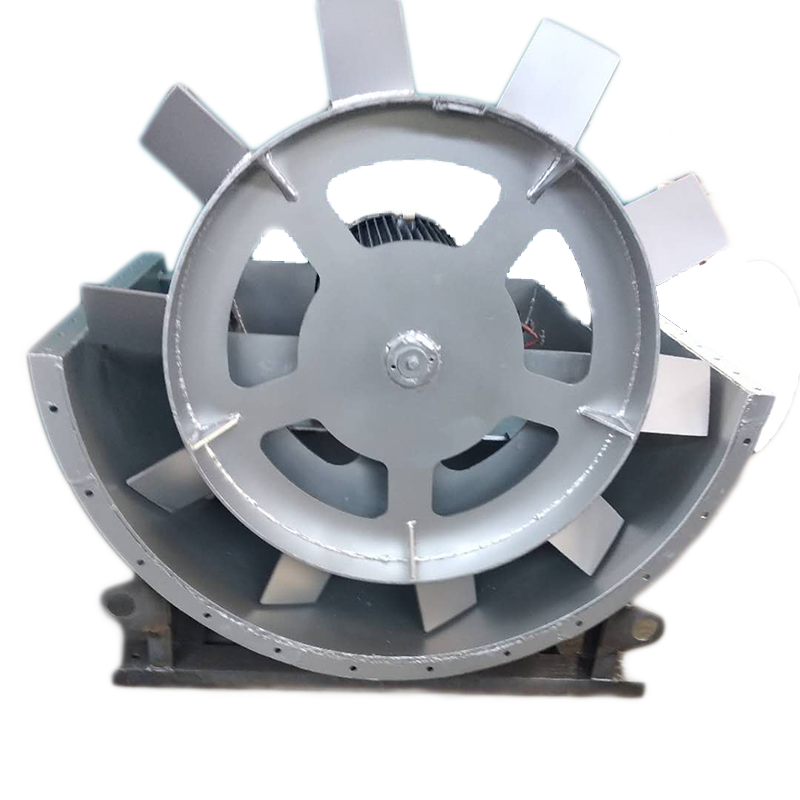

When the bearing temperature of the fan is normal, it is ≤ 70 ℃. If it rises to 70 ℃, an alarm should (will) be given if there is an electric control. At this time, the reason should be found out. First, check whether the cooling water is normal? Is the bearing oil level normal? If the cause cannot be found for a while, the bearing temperature rises rapidly to 90 ℃, and if there is an electric control, the alarm and shutdown signal shall be sent again. Hezhou Wet dust collector In the process of fan startup, shutdown or operation, if any abnormal phenomenon is found, it shall be checked immediately. If any small fault is found during the check, it shall be timely found out the cause and eliminated. In case of major fault (such as severe vibration, impact of fan, sharp rise of bearing temperature, etc.), stop the machine immediately for inspection. major Wet dust collector The lubricating oil (or grease) shall be renewed and replaced one month after the first operation of the fan. In addition to replacement after each overhaul, the lubricating oil (or grease) can be replaced once every 1~2 months under normal conditions, or according to the actual situation. Fans include fans, turbine blowers, roots blowers and turbine compressors, which are divided into 7 categories in detail, including centrifugal compressors, axial compressors, centrifugal blowers, roots blowers, centrifugal fans, axial fans and Ye's blowers

(1) Wet dust collector Price The operating environment should always be kept clean, the fan surface should be kept clean, and the air inlet and outlet should be free of sundries. Regularly remove dust and other sundries in the fan and pipe. (2) major Wet dust collector It can only be operated when the fan is completely normal. At the same time, it is necessary to maintain sufficient capacity of power supply facilities and stable voltage. Open phase operation is strictly prohibited. The power supply lines must be dedicated lines, and temporary lines should not be used for long-term power supply. (3) In case of abnormal sound, serious heating of motor, electrification of shell, tripping of switch, failure to start and other phenomena of fan during operation, the fan shall be stopped immediately for inspection. To ensure safety, maintenance is not allowed during the operation of the fan. After the maintenance, the test run shall be carried out for about five minutes, and the machine shall be restarted after confirming that there is no abnormal phenomenon. (4) Hezhou Wet dust collector Price Replenish or replace lubricating grease for bearings irregularly according to the service environmental conditions (it is not necessary to replace lubricating grease for motor enclosed bearings within the service life). To ensure good lubrication of the fan during operation, the number of times of oiling shall not be less than 1000 hours/time. For enclosed bearings and motor bearings, fill 2/3 of the inner and outer rings of bearings with ZL-3 lithium based lubricating grease. It is strictly prohibited to run without oil. (5) The fan shall be stored in a dry environment to prevent the motor from moisture. Rain proof measures shall be taken when the fan is stored in the open air. The fan shall be prevented from collision during storage and handling to avoid damage to the fan.