Kunming Centrifugal fan manufactor The development trend and direction of wind turbine in the future are analyzed as follows: wind turbine is mainly used for ventilation and air exchange in various fields of national economy and various places, such as metallurgy, petrochemical, electric power, urban rail transit, textile, shipbuilding, etc. In addition to the traditional application fields, there will still be great development prospects in more than 20 potential market fields, such as comprehensive utilization of coal gangue, new dry process clinker technology, energy saving in metallurgical industry and comprehensive utilization of resources. major Centrifugal fan With the increasing competition in the wind turbine manufacturing industry, mergers and acquisitions and capital operations among large wind turbine manufacturing enterprises are becoming increasingly frequent. Domestic outstanding wind turbine manufacturing enterprises are increasingly paying attention to the research of the industry market, especially the in-depth research of the industry development environment and product buyers. Because of this, a large number of domestic excellent fan brands have risen rapidly and become the leaders in the fan manufacturing industry!

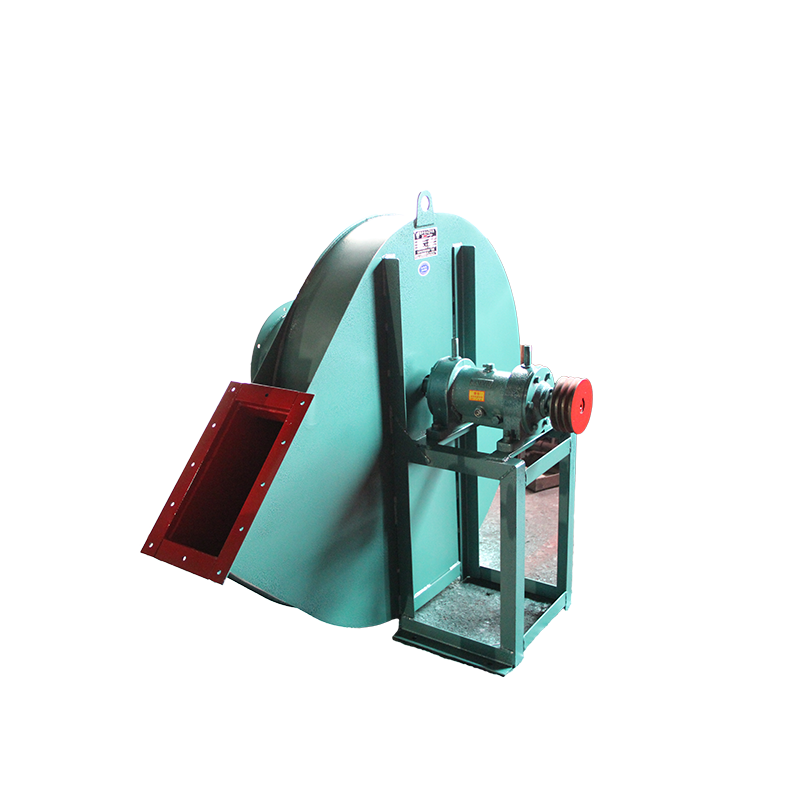

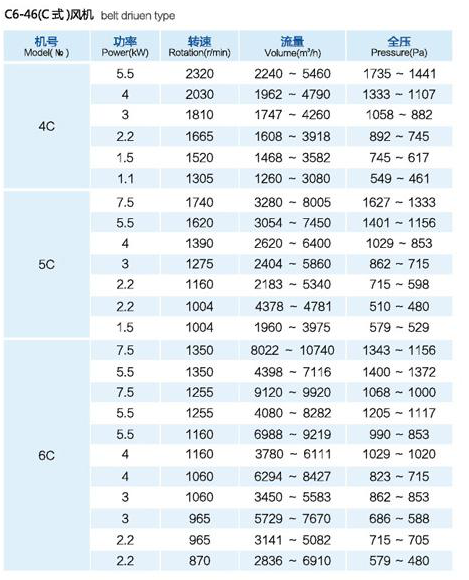

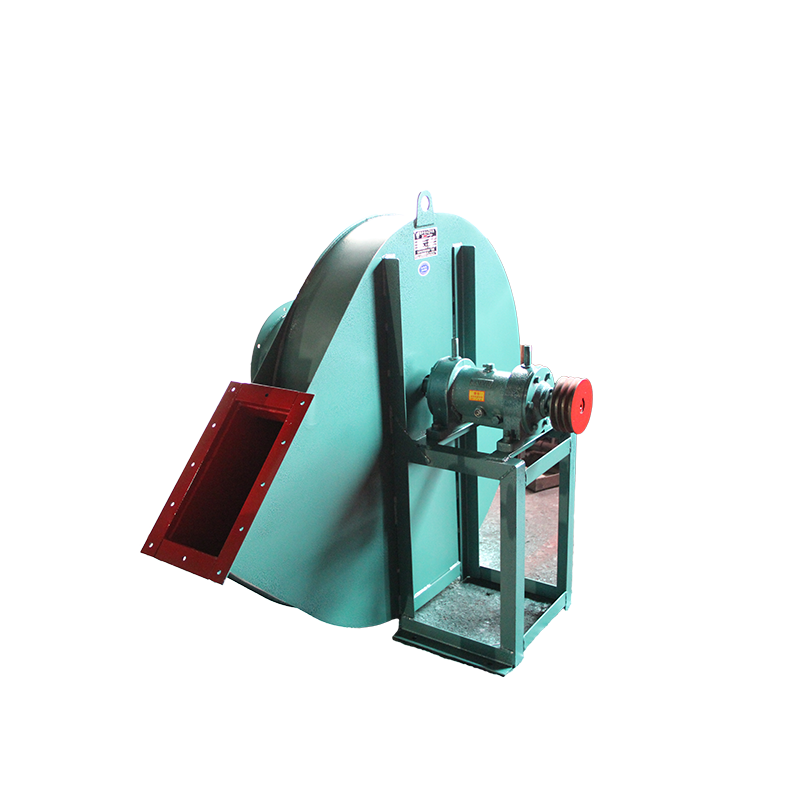

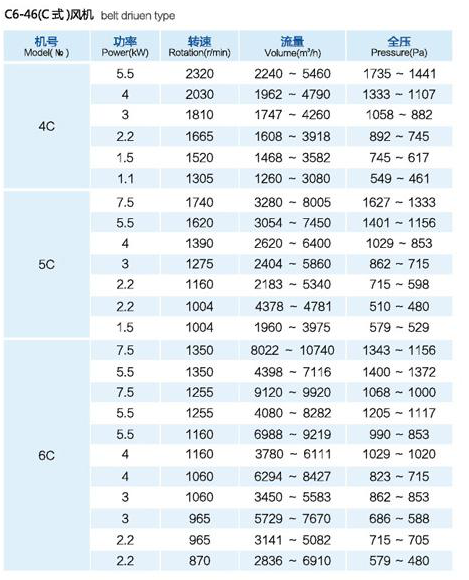

Kunming major Centrifugal fan Fan performance parameters. The performance parameters of fan mainly include flow, pressure, power, efficiency and speed. In addition, the size of noise and vibration is also the main fan design index. Flow, also known as air volume, is expressed by the volume of gas flowing through the fan in unit time; Pressure, also known as wind pressure, refers to the pressure rise value of gas in the fan, including static pressure, dynamic pressure and total pressure; Power refers to the input power of the fan, namely shaft power. The ratio of effective power of fan to shaft power is called efficiency. Centrifugal fan manufactor The total pressure efficiency of fan can reach 90%. Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; Ventilation and induced draft of boiler and industrial furnace; Cooling and ventilation in air conditioning equipment and household appliances; Drying and selection of grain; Wind source of wind tunnel and inflation and propulsion of hovercraft. The working principle of the fan is basically the same as that of the turbine compressor, but because the gas flow rate is low and the pressure changes little, it is generally unnecessary to consider the change of gas specific volume, that is, treat the gas as an incompressible fluid

The selection basis of wet dust collector is as follows. ① major Centrifugal fan Dust removal efficiency. Whether the efficiency of wet dust collector is high or not is one of the most important performance indicators to be selected. Under certain conditions, the gas flow, specific dust pollutants, and the gas state have a direct impact on the collection efficiency. ② Operational flexibility. Centrifugal fan manufactor Any operating equipment shall consider its negative flow, and the impact on the capture efficiency when the air flow exceeds or is lower than the design value; Similarly, it is necessary to know how to operate when the dust concentration is unstable or continuously higher than the design value. ③ Hydrophobicity. The purification efficiency of wet dust collector for hydrophobic dust is not high, and generally it is not suitable for the operation at the design value. ④ Adhesion. Wet dust collector can purify cohesive dust, but flushing and cleaning shall be considered to prevent blockage, ⑤ corrosiveness. Anticorrosion measures shall be considered when purifying corrosive gas, ⑥ water consumption. How much water is consumed by the dust remover, sewage treatment and anti freezing measures for water in winter. ⑦ Mud treatment. Mud treatment is an inevitable problem for wet dust collectors, and efforts should be made to reduce the harm of pollution. ⑧ Operation and maintenance. Kunming Centrifugal fan manufactor Generally, moving or rotating parts inside the dust remover shall be avoided, and it shall be noted that if the gas passes through the channel section too small, it will cause blockage.

The key points of factors to be considered in the technical approach to the transformation of wet electrostatic precipitators: the wet electrostatic precipitators built before the mid-1970s could not meet the requirements of the new emission standards because of the low requirements for boiler smoke and dust emissions, the small selection of equipment capacity, the outdated structure of electrostatic precipitators, aging of dust removal equipment, low dust removal efficiency and other reasons, These electrostatic precipitators have a problem of transformation to further improve efficiency. major Centrifugal fan manufactor The improvement measures for the original equipment should be considered from both technical and economic aspects, and the following technical approaches are generally adopted: 1. Discover the potential of electrostatic precipitator equipment. For example, adjust the rapping cycle and rapping force of the electrode to improve the corona power and reduce the re flying of dust; Improve the uneven distribution of flue gas velocity and readjust the technical parameters of the airflow distribution device; Adjust the control mode or power supply mode of the power supply equipment. 2、 major Centrifugal fan Combination with other dedusting equipment. That is, a primary precipitator is added before or after the electrostatic precipitator. 3. Increase the capacity (or dust collection area) of the electrostatic precipitator. That is, add an electric field, or increase or widen the electric field of the electrostatic precipitator.

The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Kunming major Centrifugal fan Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Centrifugal fan manufactor Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.

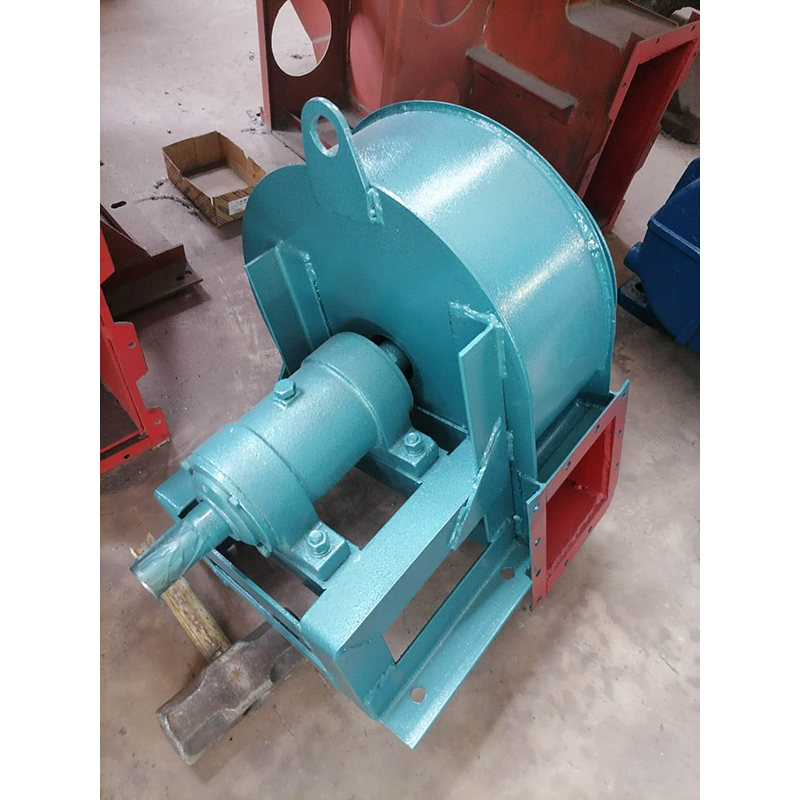

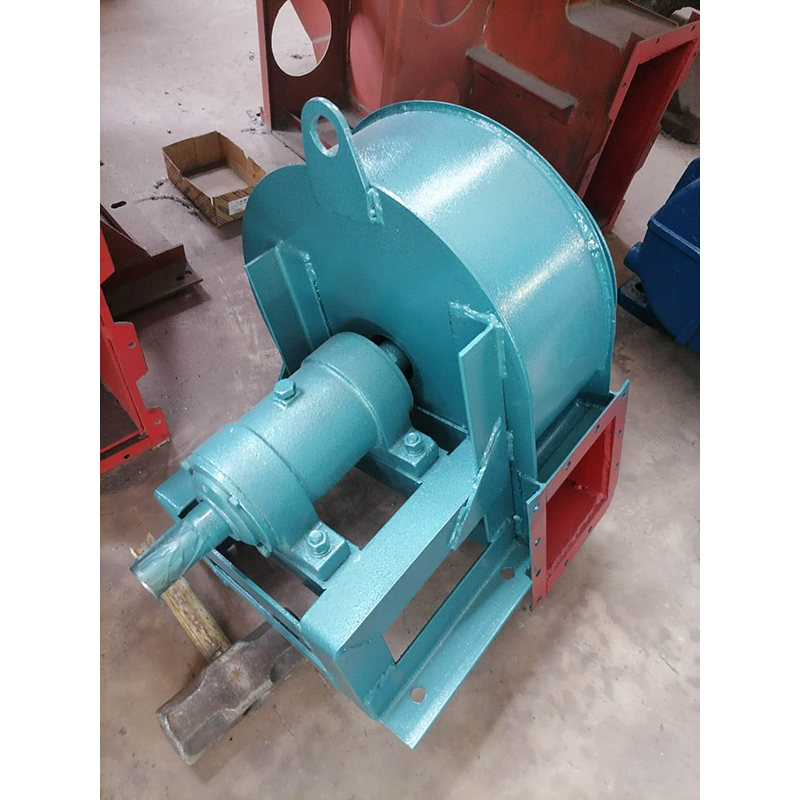

Before installation, first prepare the materials and tools for installation, and check the parts of the fan, especially the impeller, main shaft, bearing and other parts. If any damage is found, repair it, and then clean the inside of the bearing box with kerosene. In the process of installation, the following points must be paid attention to: 1. In order to prevent rust and reduce the difficulty of disassembly, some grease or machine oil should be coated on some joint surfaces. 2. When installing the bolts on the joint surface, if there are positioning pins, install the pins and tighten them before tightening the bolts. 3. Check that there should be no tools and sundries falling or left in the casing and other casings. Installed and used by CHANG factory bridge QIAO ISO9001 quality management system certification enterprise of Beijing No. 2 Blower Works 1. When installing the fan, the inlet and outlet must be provided with soft connection, and the weight of the gas transmission pipeline should not be added to the casing. Correct the gap size between the air inlet and the impeller according to the drawing, and keep the shaft in a horizontal position. 2. When installing the soft connection of the air inlet, the bolts of the air inlet itself can be directly used for connection. At this time, the air inlet is fixed by three countersunk screws.