Wet dust remover is a device that uses the action of water or other liquids and dusty gases to remove dust particles. When dust particles meet with sprayed water droplets, water films or wetted walls and devices The process of wetting, condensation, diffusion and sedimentation takes place, so it is separated from the gas to purify the gas. city in Hunan Dust exhaust centrifugal fan company It is characterized by purifying dust at the same time It can also purify gas, large Dust exhaust centrifugal fan When the flue gas contains combustible components, the use of wet dust collectors can avoid equipment explosion, and the dust removal effect can generally meet the environmental protection requirements. The equipment is small and the investment is relatively low. Therefore, there are three wet dust collectors used in dust removal projects in mining, metallurgy, machinery, light industry, building materials and other industries. Sludge containing sewage must be treated, otherwise secondary pollution may occur, Therefore, it is not widely used as dry dust collector. There are many types of wet dust collectors. According to their structures, there are the following types: ① gravity spray wet dust collectors - spray scrubbing towers; ② Cyclone wet dust collector - cyclone water film dust collector, water film dust collector; ③ Self excited wet dust collector - impulse dust collector, water bath dust collector; ④ Packed wet dust collector - packed tower, turbulent ball tower; ⑤ Foam wet dust collector - foam dust collector Cyclone dust collector, leaky plate tower; ⑥ Venturi wet dust collector - Venturi tube dust collector; ⑦ Mechanical induction wet dust collector - water wheel dust collector.

large Dust exhaust centrifugal fan The wet electrostatic precipitator mainly has two structural forms. One is to use corrosion-resistant conductive materials (which can be non-metallic materials with excellent conductivity or metal materials with corrosion-resistant characteristics) as the dust collector, and the other is to use non-conductive non-metallic materials as the dust collector by forming a conductive water film through water spray or overflow. Wet electrostatic precipitators can also be divided into cross flow type (horizontal) and vertical flow type (vertical) according to the flow direction of waste gas. The cross flow type is mostly plate structure, city in Hunan Dust exhaust centrifugal fan The gas flows in and out in the horizontal direction, and the structure is similar to the dry electrostatic precipitator; The vertical flow type is mostly tubular structure, and the gas flow direction is vertical. Generally speaking, the efficiency of vertical flow wet electrostatic precipitator is twice as high as that of cross flow wet electrostatic precipitator under the condition of the same ventilation cross-sectional area. The dust deposited on the electrode plate can be washed down by water. Wet dust removal can avoid the re flying of captured dust and achieve high dust removal efficiency. Since there is no rapping device, the operation is also more reliable. The device that forms conductive film on the surface of the dust collector by means of water spray or overflow water has problems of corrosion, sludge and sewage treatment. It is only used when the dust concentration of the gas is low and the dust removal efficiency is required to be high; The wet electrostatic precipitator using corrosion-resistant conductive materials as dust collector does not need long-term water spraying or overflow water, Dust exhaust centrifugal fan company Regular flushing is only carried out according to the operating conditions of the system, and only a small amount of water is consumed. This part of water can be recycled, and the dust collection system is basically free of secondary pollution.

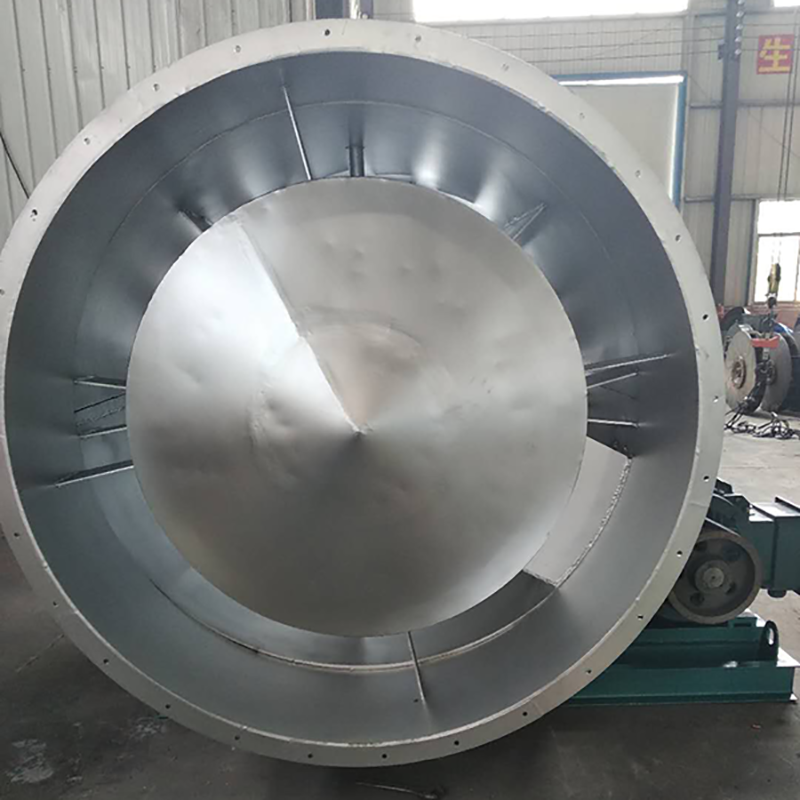

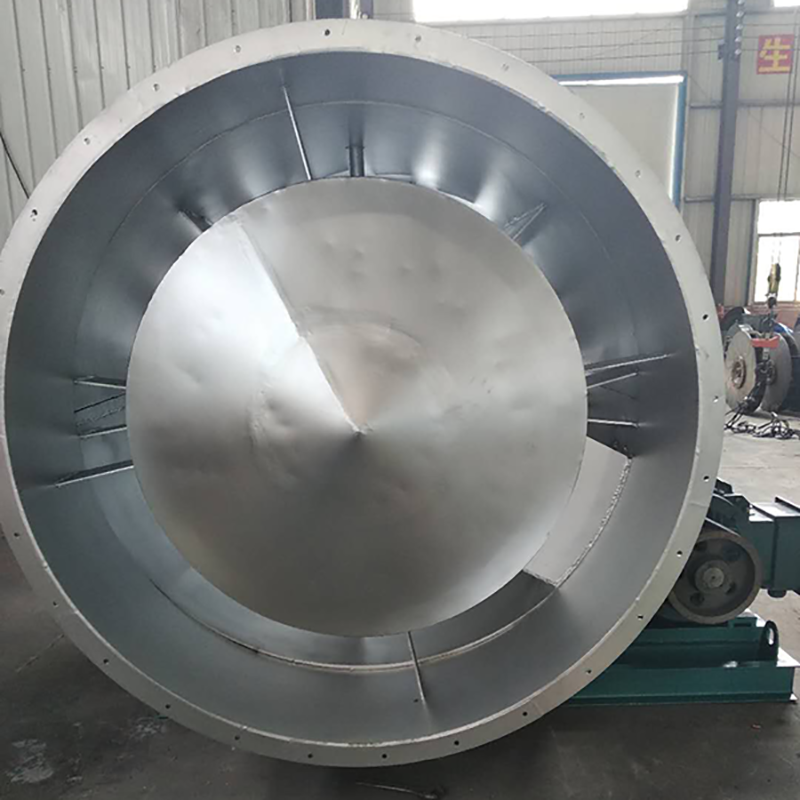

Correct maintenance is an important guarantee for the safe and reliable operation of the fan and the improvement of its service life. Therefore, Dust exhaust centrifugal fan company When using fans, full attention must be paid. Impeller maintenance: at the initial stage of impeller operation and during all regular inspections, whenever there is an opportunity, the impeller must be checked for cracks, wear, dust and other defects. The impeller must be kept clean whenever possible, large Dust exhaust centrifugal fan The steel wire brush shall be used regularly to remove the dust and rust on the impeller. As the travel time increases, the dust can not be evenly attached to the impeller, which will cause damage to the balance of the impeller and even cause rotor vibration. As long as the impeller is repaired, it needs to be dynamically balanced again. If possible, the portable trial dynamic balancing instrument can be used for on-site balancing. Before dynamic balancing, check whether all fastening bolts are tightened. Since the impeller has been operating in an unbalanced state for a period of time, these bolts may have become loose. Bearing maintenance: frequently check the oil supply of bearing lubricating oil. If the box leaks oil, tighten the bolts of the end cover a little. If this is not enough, you may have to use new sealing packing. When the bearing lubricating oil is in normal use, it should be replaced at least once every six months. When it is used for the first time, it should be done after 200 hours of operation. The second oil change should be done in 1 to 2 months. After that, the lubricating oil should be checked once a week. If the lubricating oil does not deteriorate, the oil change can be extended to 2 to 4 months. The specified brand of lubricating oil (specified on the general drawing) must be used when replacing, The old oil in the oil tank shall be completely drained and cleaned before new oil can be filled. If the fan bearing needs to be replaced, pay attention to the following matters: before installing the new bearing, the bearing and bearing box must be very clean. Place the bearing in the oil with a temperature of about 70~80 ℃ and heat it before installing it on the shaft. Do not force assembly to avoid damaging the shaft. Maintenance of other supporting equipment: see the respective user manual for the maintenance of various supporting equipment, including motors, electric actuators, instruments, meters, etc. These operating instructions are provided by each supporting manufacturer. The manufacturer will pack these instructions together and provide them to the user

According to the report data released by the Global Wind Energy Council, the new installed capacity of global wind power in 2014 was 51477MW, up 44% year on year, and the cumulative installed capacity exceeded the threshold of 50GW for the first time. All data set new world records. China's wind power industry has driven global growth. In 2014, China's new installed capacity of wind power was 23350500 kilowatts, 45.1% higher than that of the previous year, large Dust exhaust centrifugal fan The cumulative installed capacity has reached nearly 115 million kilowatts, of which the grid connected capacity is nearly 100 million kilowatts, accounting for 7% of the total installed power generation capacity. In addition to the strength of wind power itself, the recovery of the wind power industry has also contributed to the decline of coal prices. The decline of fuel costs has led to the profitability of most power enterprises hitting a new high in 2014, Dust exhaust centrifugal fan company This can expand the scale of wind power construction and accelerate the payment of unit arrears. As a result, the performance of wind power equipment manufacturers was in full swing in 2014, the market concentration was further improved to the top eight complete machine enterprises, and China's wind power industry basically ended the situation of low price competition. The wind power industry generally believes that the wind power industry will enter a new normal of stable growth in the future. In the next five years, the annual new installed capacity may reach at least 20 million kilowatts, and there is still a bottleneck for developers to improve their profits.

Main working principles of wet electrostatic precipitator: large Dust exhaust centrifugal fan Spray the water mist to the discharge electrode and corona area, the water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode, and the collision interception, adsorption and coagulation of electric field force and charged water mist will jointly trap the dust particles, and finally the dust particles will reach the dust collector under the drive of electric field force and be trapped. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, city in Hunan Dust exhaust centrifugal fan First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, Dust exhaust centrifugal fan company Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.

city in Hunan large Dust exhaust centrifugal fan Installation requirements a. The foundation of the fan shall be level and solid, and the foundation height shall be ≥ 200mm. b. The fan and air duct shall be connected by flexible hose (flexible material and non combustible), the length shall not be less than 200mm, and the pipe diameter shall be the same as the inlet and outlet size of the fan. In order to ensure that the hose will not be twisted or deformed during the system operation, it should be installed with appropriate tightness. The canvas hose installed at the suction end of the fan can be slightly tightened to prevent the fan from being sucked in during operation and reduce the sectional size of the canvas hose. c、 Dust exhaust centrifugal fan company The steel support of the fan must be fixed on the concrete foundation, and a rubber damping pad must be added between the steel support of the fan and the foundation. All fan and motor components are installed on the whole steel support, and the steel ground frame is installed on the damping pad at the top of the foundation. The damping pad is preferably made of perforated rubber plates. d. The pipe diameter at the outlet of the fan can only be increased, but not decreased. At the end of the outlet, an insect screen should be installed. When the fan is inclined to the upper outlet, a rain cap should be added