According to the report data released by the Global Wind Energy Council, the new installed capacity of global wind power in 2014 was 51477MW, up 44% year on year, and the cumulative installed capacity exceeded the threshold of 50GW for the first time. All data set new world records. China's wind power industry has driven global growth. In 2014, China's new installed capacity of wind power was 23350500 kilowatts, 45.1% higher than that of the previous year, large Boiler centrifugal fan The cumulative installed capacity has reached nearly 115 million kilowatts, of which the grid connected capacity is nearly 100 million kilowatts, accounting for 7% of the total installed power generation capacity. In addition to the strength of wind power itself, the recovery of the wind power industry has also contributed to the decline of coal prices. The decline of fuel costs has led to the profitability of most power enterprises hitting a new high in 2014, Boiler centrifugal fan company This can expand the scale of wind power construction and accelerate the payment of unit arrears. As a result, the performance of wind power equipment manufacturers was in full swing in 2014, the market concentration was further improved to the top eight complete machine enterprises, and China's wind power industry basically ended the situation of low price competition. The wind power industry generally believes that the wind power industry will enter a new normal of stable growth in the future. In the next five years, the annual new installed capacity may reach at least 20 million kilowatts, and there is still a bottleneck for developers to improve their profits.

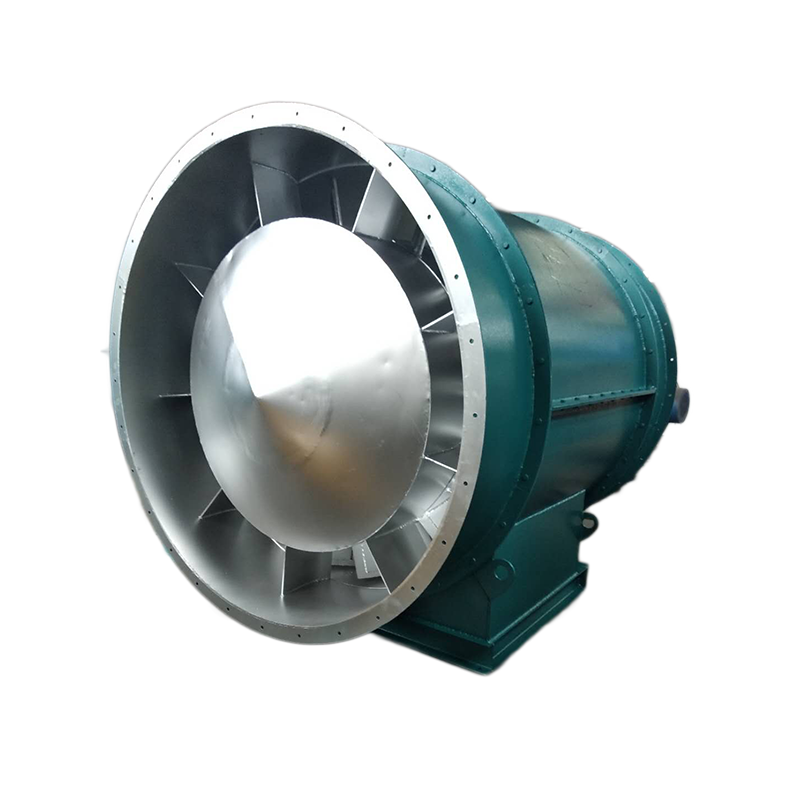

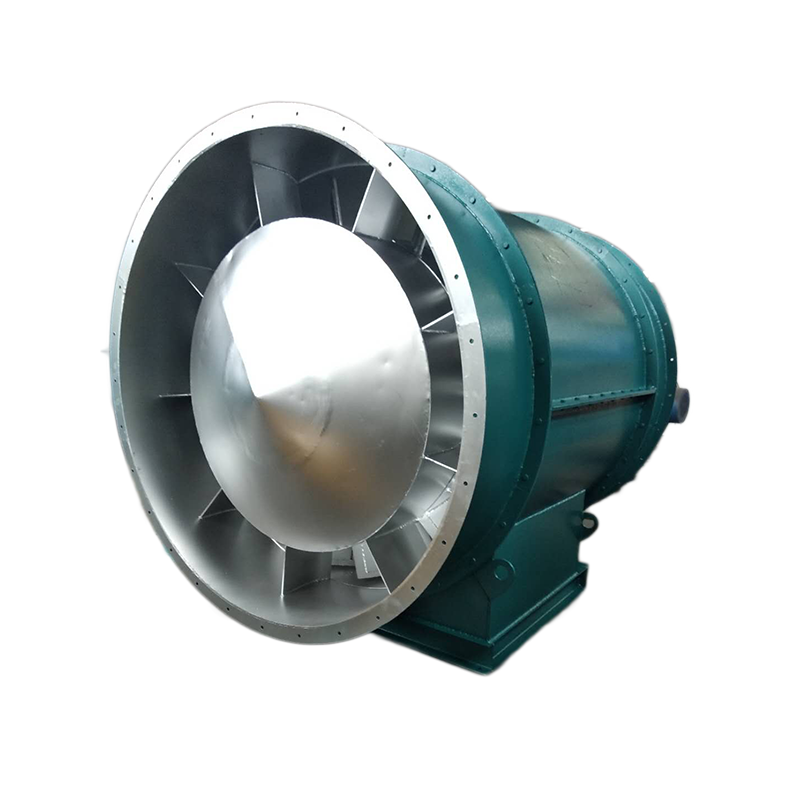

large Boiler centrifugal fan The fan is a kind of driven fluid machinery, which relies on the input mechanical energy to increase the gas pressure and discharge gas. Fan is the abbreviation of Chinese custom for gas compression and gas transmission machinery. Generally speaking, fans include fans, blowers, and wind turbines. Southwest Guizhou Boiler centrifugal fan company Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings, as well as ventilation and induced draft of boilers and industrial furnaces; Cooling and ventilation in air conditioning equipment and household appliances; Drying and delivery of grain, wind source of wind tunnel and inflation and propulsion of hovercraft

The key points of factors to be considered in the technical approach to the transformation of wet electrostatic precipitators: the wet electrostatic precipitators built before the mid-1970s could not meet the requirements of the new emission standards because of the low requirements for boiler smoke and dust emissions, the small selection of equipment capacity, the outdated structure of electrostatic precipitators, aging of dust removal equipment, low dust removal efficiency and other reasons, These electrostatic precipitators have a problem of transformation to further improve efficiency. large Boiler centrifugal fan company The improvement measures for the original equipment should be considered from both technical and economic aspects, and the following technical approaches are generally adopted: 1. Discover the potential of electrostatic precipitator equipment. For example, adjust the rapping cycle and rapping force of the electrode to improve the corona power and reduce the re flying of dust; Improve the uneven distribution of flue gas velocity and readjust the technical parameters of the airflow distribution device; Adjust the control mode or power supply mode of the power supply equipment. 2、 large Boiler centrifugal fan Combination with other dedusting equipment. That is, a primary precipitator is added before or after the electrostatic precipitator. 3. Increase the capacity (or dust collection area) of the electrostatic precipitator. That is, add an electric field, or increase or widen the electric field of the electrostatic precipitator.

The selection basis of wet dust collector is as follows. ① large Boiler centrifugal fan Dust removal efficiency. Whether the efficiency of wet dust collector is high or not is one of the most important performance indicators to be selected. Under certain conditions, the gas flow, specific dust pollutants, and the gas state have a direct impact on the collection efficiency. ② Operational flexibility. Boiler centrifugal fan company Any operating equipment It is necessary to take into account its negative circulation and the impact on the capture efficiency when the air flow rate exceeds or is lower than the design value; Similarly, it is necessary to know how to operate when the dust concentration is unstable or continuously higher than the design value. ③ Hydrophobicity. The purification efficiency of wet dust collector for hydrophobic dust is not high, and generally it is not suitable for the operation at the design value. ④ Adhesion. Wet dust collector can purify cohesive dust, but flushing and cleaning shall be considered to prevent blockage, ⑤ corrosiveness. Anticorrosion measures shall be considered when purifying corrosive gas, ⑥ water consumption. How much water is consumed by the dust remover, sewage treatment and anti freezing measures for water in winter. ⑦ Mud treatment. Mud treatment is an inevitable problem for wet dust collectors, and efforts should be made to reduce the harm of pollution. ⑧ Operation and maintenance. Southwest Guizhou Boiler centrifugal fan company Generally, moving or rotating parts inside the dust remover shall be avoided, and it shall be noted that if the gas passes through the channel section too small, it will cause blockage.

Correct maintenance is an important guarantee for the safe and reliable operation of the fan and the improvement of its service life. Therefore, Boiler centrifugal fan company When using fans, full attention must be paid. Impeller maintenance: at the initial stage of impeller operation and during all regular inspections, whenever there is an opportunity, the impeller must be checked for cracks, wear, dust and other defects. The impeller must be kept clean whenever possible, large Boiler centrifugal fan The steel wire brush shall be used regularly to remove the dust and rust on the impeller. As the travel time increases, the dust can not be evenly attached to the impeller, which will cause damage to the balance of the impeller and even cause rotor vibration. As long as the impeller is repaired, it needs to be dynamically balanced again. If possible, the portable trial dynamic balancing instrument can be used for on-site balancing. Before dynamic balancing, check whether all fastening bolts are tightened. Since the impeller has been operating in an unbalanced state for a period of time, these bolts may have become loose. Bearing maintenance: frequently check the oil supply of bearing lubricating oil. If the box leaks oil, tighten the bolts of the end cover a little. If this is not enough, you may have to use new sealing packing. When the bearing lubricating oil is in normal use, it should be replaced at least once every six months. When it is used for the first time, it should be done after 200 hours of operation. The second oil change should be done in 1 to 2 months. After that, the lubricating oil should be checked once a week. If the lubricating oil does not deteriorate, the oil change can be extended to 2 to 4 months. The specified brand of lubricating oil (specified on the general drawing) must be used when replacing, The old oil in the oil tank shall be completely drained and cleaned before new oil can be filled. If the fan bearing needs to be replaced, pay attention to the following matters: before installing the new bearing, the bearing and bearing box must be very clean. Place the bearing in the oil with a temperature of about 70~80 ℃ and heat it before installing it on the shaft. Do not force assembly to avoid damaging the shaft. Maintenance of other supporting equipment: see the respective user manual for the maintenance of various supporting equipment, including motors, electric actuators, instruments, meters, etc. These operating instructions are provided by each supporting manufacturer. The manufacturer will pack these instructions together and provide them to the user

The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Southwest Guizhou large Boiler centrifugal fan Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Boiler centrifugal fan company Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.