customized Wet dedusting equipment Fans can be divided into axial flow fans, centrifugal fans and diagonal flow (mixed flow) fans according to the flow direction after the airflow enters the impeller. Fans are divided into press in local fans (hereinafter referred to as press in fans) and flame-proof motors placed outside or inside the flow channel, and flame-proof motors placed inside the explosion-proof sealing chamber of the extraction type local fans (hereinafter referred to as extraction fans) according to their purposes. Wet dedusting equipment Price Fans can also be divided into single-stage, two-stage or multi-stage pressurization fans according to the form of pressurization. For example, 4-72 is single-stage pressurization, and high-end fan is multi-stage pressurization fan. Fans can be divided into axial flow fans, mixed flow fans, roof fans, air conditioning fans, etc. Fan can be divided into negative pressure fan, low pressure fan, medium pressure fan and high pressure fan according to pressure. According to the outlet pressure (pressure rise), it can be divided into: ventilator (≤ 15000 Pa), blower (15-350000 Pa), compressor (≥ 350000 Pa)

Main working principles of wet electrostatic precipitator: customized Wet dedusting equipment Spray the water mist to the discharge electrode and corona area. The water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode. The collision interception, adsorption and coagulation of electric field force and charged water mist will jointly trap the dust particles. Finally, the dust particles will reach the dust collecting electrode and be trapped under the drive of electric field force. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, Wuzhou Wet dedusting equipment First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, Wet dedusting equipment Price Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.

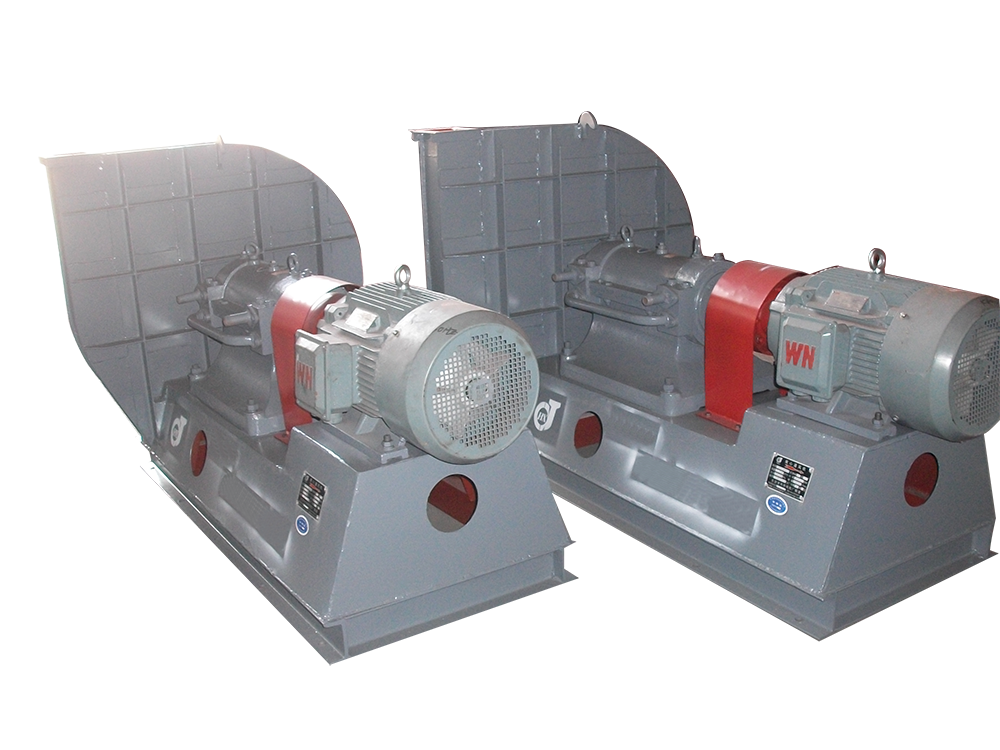

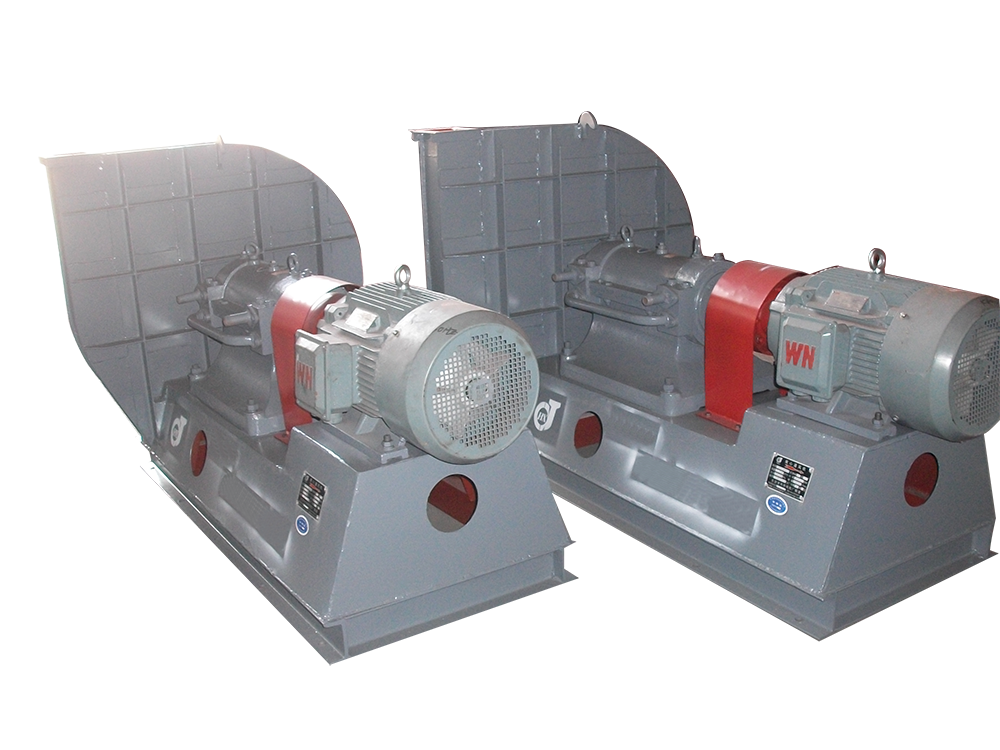

Before installation, first prepare the materials and tools for installation, and check the parts of the fan, especially the impeller, main shaft, bearing and other parts. If any damage is found, repair it, and then clean the inside of the bearing box with kerosene. In the process of installation, the following points must be paid attention to: 1. In order to prevent rust and reduce the difficulty of disassembly, some grease or machine oil should be coated on some joint surfaces. 2. When installing the bolts on the joint surface, if there are positioning pins, install the pins and tighten them before tightening the bolts. 3. Check that there should be no tools and sundries falling or left in the casing and other casings. Installed and used by CHANG factory bridge QIAO ISO9001 quality management system certification enterprise of Beijing No. 2 Blower Works 1. When installing the fan, the inlet and outlet must be provided with soft connection, and the weight of the gas transmission pipeline should not be added to the casing. Correct the gap size between the air inlet and the impeller according to the drawing, and keep the shaft in a horizontal position. 2. When installing the soft connection of the air inlet, the bolts of the air inlet itself can be directly used for connection. At this time, the air inlet is fixed by three countersunk screws.

Wuzhou Wet dedusting equipment Price The development trend and direction of wind turbine in the future are analyzed as follows: wind turbine is mainly used for ventilation and air exchange in various fields of national economy and various places, such as metallurgy, petrochemical, electric power, urban rail transit, textile, shipbuilding, etc. In addition to the traditional application fields, there will still be great development prospects in more than 20 potential market fields, such as comprehensive utilization of coal gangue, new dry process clinker technology, energy saving in metallurgical industry and comprehensive utilization of resources. customized Wet dedusting equipment With the increasing competition in the wind turbine manufacturing industry, mergers and acquisitions and capital operations among large wind turbine manufacturing enterprises are becoming increasingly frequent. Domestic outstanding wind turbine manufacturing enterprises are increasingly paying attention to the research of the industry market, especially the in-depth research of the industry development environment and product buyers. Because of this, a large number of domestic excellent fan brands have risen rapidly and become the leaders in the fan manufacturing industry!

Wet dedusting equipment Price The work starts before the fan is used. one Wuzhou Wet dedusting equipment Price Carefully read the fan operation instructions and product samples, and be familiar with and understand the fan specifications, forms, impeller rotation direction and air flow in and out direction; Check whether all parts of the fan are in good condition again, or they can be installed and used only after being repaired. 2. The fan must be installed with safety devices to prevent accidents, and installed and wired by professionals familiar with relevant safety requirements. 3. The air duct connecting the inlet and outlet of the fan has separate support, and it is not allowed to add the overlapping weight of the duct to the components of the fan; When installing the fan, pay attention to the horizontal position of the fan, and adjust the connection between the joint surface of the fan and the foundation and the air outlet pipe to make it coincide naturally. Forced connection is not allowed. four customized Wet dedusting equipment After the fan is installed, move the impeller by hand or lever to check whether it is too tight or rubbed, and whether there is any object that hinders the rotation. The test run can be carried out only when there is no abnormal phenomenon. The exposed part of the fan transmission device should be equipped with a protective cover (provided by the user). If the fan inlet is not connected, a protective screen or other installation device (provided by the user) should also be added. 5. The power distribution control box of the fan must match the corresponding fan (power, voltage, pneumatic mode, control mode, etc.). 6. The fan wiring should be made by a professional electrician, and the wiring must be correct and reliable. Especially, the wiring number at the electric control box should be consistent with the number on the fan terminal. The fan shell should be reliably grounded. The grounding must be reliable, and zero connection cannot be used instead of grounding. 7. After all fans are installed, check whether there are any left tool box sundries inside the fan

9. Since the flow, total pressure, main shaft speed and shaft power of the fan have a fixed relationship, the main shaft speed should not be changed when the motor capacity does not change. If the main shaft speed increases, the motor may be burned due to overload. The motor power used by the fan refers to the power not required when the air inlet and outlet are fully open in terms of mechanical losses and due reserves under a specific mine. If the outlet or inlet of the fan is not connected to the pipeline or is idle without external resistance, the motor may also be burned out. For safety, a valve shall be added to the outlet or inlet pipeline of the fan, and it shall be closed when starting the motor. After turning, the valve shall be slowly opened until the specified working condition is reached, and attention shall be paid to whether the current of the motor exceeds the specified value. High power motors must be started in proper ways, such as voltage reduction, frequency conversion, etc.