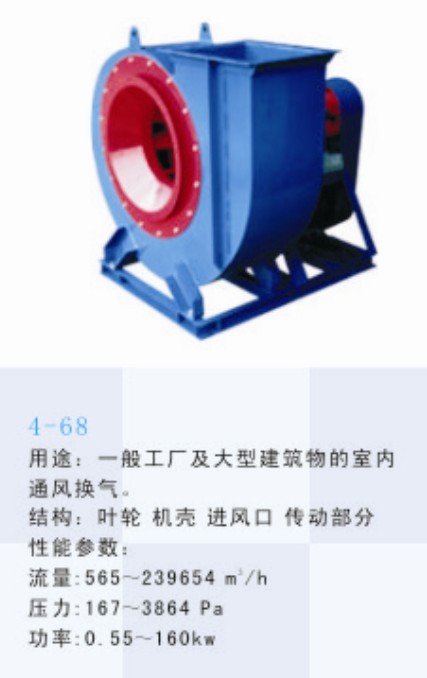

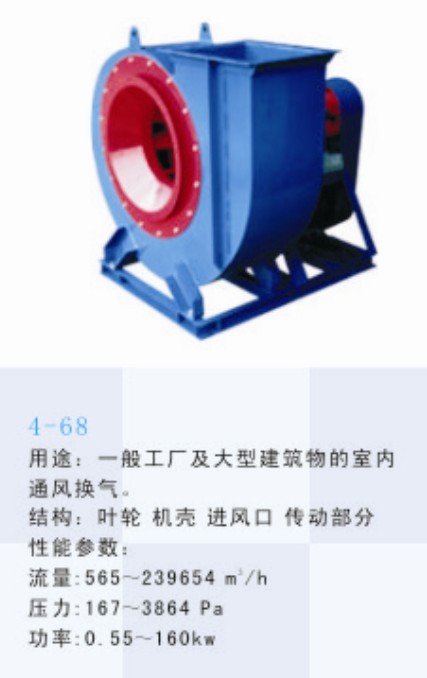

Gas compression and gas transmission machinery is a machine that converts rotating mechanical energy into gas pressure energy and kinetic energy and transports gas. The main structural components of the fan are impeller, casing, air inlet, support, motor, pulley, coupling, silencer, transmission parts (bearings), etc. large Wet dust collector The unpowered fan uses the air thermal convection caused by the natural wind force and the indoor and outdoor temperature difference to drive the turbine to rotate, thus using the centrifugal force and negative pressure effect to exhaust the indoor stale hot air. Ningbo Wet dust collector company The fan is related to the transmission and distribution energy consumption of the system, and is a very critical part of building energy conservation. According to the fan inspection conducted by the National Air Conditioning Equipment Quality Supervision and Inspection Center for many years, many fans have problems under rated conditions, so it is necessary to produce and manufacture fans in strict accordance with product standards. large Wet dust collector At the beginning of the fan operation, the vibration of the bearing is very small, but with the extension of the operating time, the dust in the fan will be unevenly attached to the impeller, gradually destroying the dynamic balance of the fan, making the bearing vibration gradually increase. Once the vibration reaches the maximum allowable value of 11mm/s of the fan (the maximum allowable value expressed by the amplitude value is as follows), The fan must be shut down for repair (dust accumulation shall be removed and dynamic balance shall be redone). Because it is very dangerous at this time, users must not use it forcibly. When the fan vibration is close to the dangerous value, the vibration measuring instrument will give an alarm.

(2) Precautions for normal operation of fan 1. If the flow is found to be too large, which does not meet the operating requirements, or less flow is required in a short time, the throttling device can be used to adjust to meet the operating requirements. 2. The sensitivity of thermometer and oil pointer shall be checked regularly. 3. In case of any abnormal phenomenon during the start-up, shutdown or operation of the fan, it shall be checked in time. 4. For minor faults found in the inspection, find out the causes in time and try to eliminate or deal with them. If minor faults cannot be eliminated or major faults are found, repair them immediately. 5. In addition to replacing the lubricating oil during each maintenance, the lubricating oil shall also be replaced regularly. Observe the oil level at ordinary times and replenish lubricating oil in time.

Wet dust collector company Forecast from the characteristics of fan demand. large Wet dust collector For small and medium-sized fans with large usage and wide range, the product structure and manufacturing process are relatively simple, and the cost is also low. Users mainly pursue high efficiency, low noise, long life, and low price. The other is capital and technology intensive. The product structure is complex, the manufacturing cycle is long, and the completeness and systematicness are also strong. Moreover, it operates under high pressure, high temperature and high speed conditions, and some even operate under severe conditions. Users have different requirements for this type of fan. For turbine blowers, compressors and large ventilators, users mainly pursue high quality, high reliability, smooth operation and long cycle

The selection of fans Product performance and fan performance listed in the selection table are based on the performance of delivering air under standard conditions. Therefore, when the use condition is non-standard, the H4-72-12 centrifugal fan must convert the use performance into the performance under standard conditions according to the relationship in the table above, and then select according to the performance and selection table. (3) Treatment of excessive or insufficient flow During use, excessive or insufficient flow often occurs. There are many reasons for this phenomenon. If the flow is high and low during use, it is mainly because the resistance in the pipe network is high and low, or the fan works in a non working area. If it is gradually reduced after a long time during use, it is mainly due to pipe network blockage. After the fan is newly installed, the flow is too large or insufficient during the formal operation. The main reasons for this phenomenon are as follows: 1. The actual value of pipe network resistance is too different from the calculated value. In the general pipe network characteristic equation, H=KQ2, if the actual value K of K-resistance coefficient is less than the calculated value K, the flow will increase; If the actual value K is greater than the calculated value K, the flow decreases. See (b) below.

While meeting the new standard, the wet electrostatic precipitator can also control the haze fine particles, sulfur trioxide aerosol droplets, organic pollutants, heavy metal pollutants, etc., which has great social benefits. The air pollutant control mode of SCR+ESP/FF+WFGD+WESP is also a relatively effective way to control pollutants in Shangshan Coal fired Power Plant. Wet dust collector company Common dust control technologies, among which the dry electrostatic precipitator, the electrostatic fabric composite precipitator and the bag type precipitator are used as the front section dust control technology, cannot guarantee the ultra clean emission of flue gas dust after the desulfurization device, while the wet electrostatic precipitator arranged at the downstream of the wet desulfurization device will be used as a reliable terminal dust control technology. The working principle of wet electrostatic precipitator is similar to that of dry electrostatic precipitator. It is high-voltage corona discharge that charges dust or water mist, and charged particles reach the dust collecting plate under the action of electric field force, large Wet dust collector However, in terms of the way of dust, the dry electrostatic precipitator uses mechanical vibration, while the wet electrostatic precipitator uses flushing fluid to flush electricity, washing the dust captured on the dust collection plate into the ash hopper and then discharging the wet electrostatic precipitator. The advantages of the wet electrostatic precipitator are: because the mass and heat transfer processes occur simultaneously in the process of gas and liquid contact, this type of precipitator has the function of dust removal, It also has the function of flue gas cooling and absorption of harmful gases. Suitable for high temperature. High temperature, flammable, explosive and harmful gases; Normal operation and high purification efficiency; Dust and gas that can be used for gathering fog and dust; Exhaust volume balance; Simple structure. Low investment, convenient operation and maintenance.

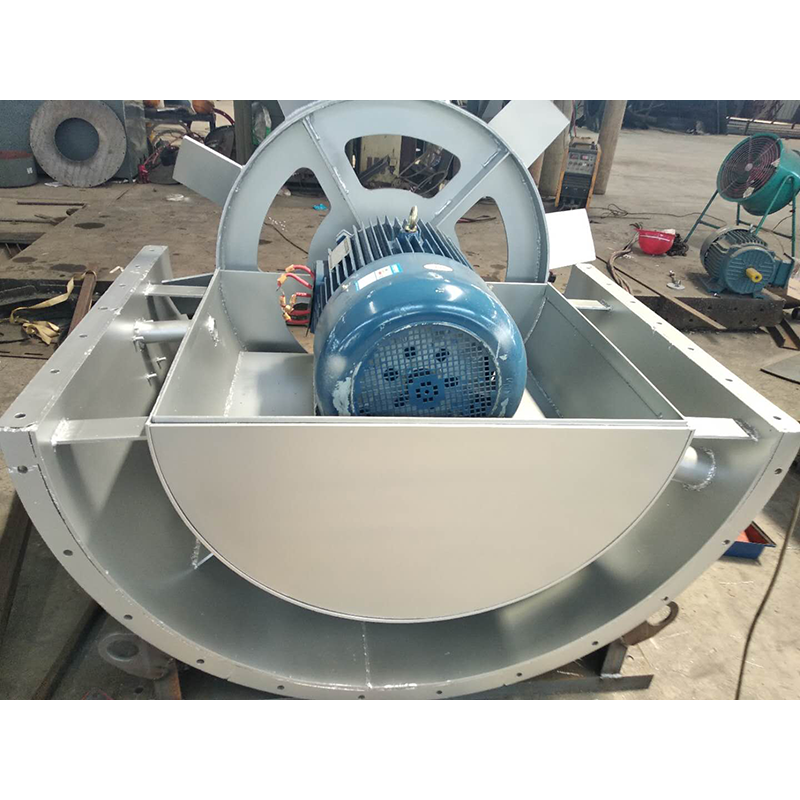

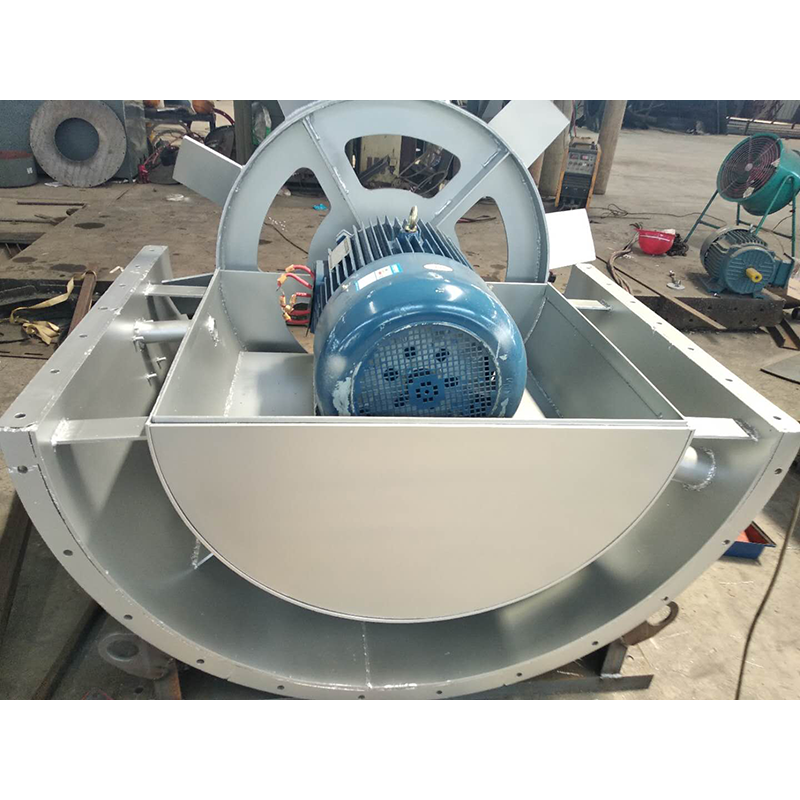

3. When installing Type C and Type B, ensure that the two pulley positions are on the same plane, and the flatness tolerance is 0.5mm. 4. When installing Type D, use a dial indicator and feeler gauge to measure the coaxiality of the fan spindle and motor spindle and the parallelism of both ends of the coupling. The coaxiality tolerance of two shafts is 0.2mm, the parallelism tolerance of both ends of the coupling is 0.2mm, and the spacing between two planes of the coupling is 5 to 8mm. 5. After the fan is installed, move the rotor with hand or lever to check whether it is too tight or collided. The test run can be carried out without overtightening or collision. 6. After the motor is installed, the belt pulley or coupling guard shall be installed. If the air inlet is not connected to the air inlet pipe, the guard net or other safety devices (provided by the user) shall also be provided. 7. Other parts shall be installed according to the corresponding positions in the drawing. 8. Add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window.