While meeting the new standard, the wet electrostatic precipitator can also control the haze fine particles, sulfur trioxide aerosol droplets, organic pollutants, heavy metal pollutants, etc., which has great social benefits. The air pollutant control mode of SCR+ESP/FF+WFGD+WESP is also a relatively effective way to control pollutants in Shangshan Coal fired Power Plant. Wet electrostatic precipitator company Common dust control technologies, among which the dry electrostatic precipitator, the electrostatic fabric composite precipitator and the bag type precipitator are used as the front section dust control technology, cannot guarantee the ultra clean emission of flue gas dust after the desulfurization device, while the wet electrostatic precipitator arranged at the downstream of the wet desulfurization device will be used as a reliable terminal dust control technology. The working principle of wet electrostatic precipitator is similar to that of dry electrostatic precipitator. It is high-voltage corona discharge that charges dust or water mist, and charged particles reach the dust collecting plate under the action of electric field force, large Wet electrostatic precipitator However, in terms of the way of dust, the dry electrostatic precipitator uses mechanical vibration, while the wet electrostatic precipitator uses flushing fluid to flush electricity, washing the dust captured on the dust collection plate into the ash hopper and then discharging the wet electrostatic precipitator. The advantages of the wet electrostatic precipitator are: because the mass and heat transfer processes occur simultaneously in the process of gas and liquid contact, this type of precipitator has the function of dust removal, It also has the function of flue gas cooling and absorption of harmful gases. Suitable for high temperature. High temperature, flammable, explosive and harmful gases; Normal operation and high purification efficiency; Dust and gas that can be used for gathering fog and dust; Exhaust volume balance; Simple structure. Low investment, convenient operation and maintenance.

large Wet electrostatic precipitator The reasons for failure caused by unstable operation are: improper temperature control of insulator box; The gas distributor grid is blocked, and the sediment electrode has too thick scale; Improper adjustment of water film; The oxygen content in the system exceeds the standard. ① Insufficient steam pressure and blocked steam pipeline may cause low temperature of insulator box. In the long run, the insulator surface temperature is low, and tar and dust particles accumulate, causing electric field short circuit. If the temperature of insulator box rises too fast, or the temperature changes violently during operation, the insulator will be cracked. ② Wet electrostatic precipitator company If intermittent flushing cannot be carried out as required during operation, the tar accumulated on the sediment pipe wall is difficult to be thoroughly cleaned, which, accumulated over time, not only causes excessive resistance to equipment operation, but also leads to damage to the electric field. ③ During maintenance, the water film is not adjusted as required, the water film is uneven or not thick enough, and after putting into operation, the phenomenon described in fault (4) will occur. The above situation also occurs when the water film is damaged during operation. ④ The reason for the explosion of the electrostatic precipitator is that the oxygen content in the gas exceeds the standard, the mixed explosive gas is formed in the equipment and reaches the explosion limit, and the explosion occurs when encountering electric sparks.

Qiannan large Wet electrostatic precipitator WESP has the advantages of high dust removal efficiency, small pressure loss, simple operation, low energy consumption, no moving parts, no secondary dust, low maintenance costs, short production downtime, can work below the flue gas dew point temperature, can be combined with other flue gas treatment equipment due to its compact structure, and diversified design forms. The wet electrostatic precipitator uses liquid to wash the dust collector surface for dust removal, which can effectively collect fine particles (PM2.5 dust, SO3 acid mist, aerosol), heavy metals (Hg As、Se、Pb、Cr)、 Organic pollutants (PAHs, dioxins), etc. After the wet electrostatic precipitator is used, the smoke and dust emission in the wet flue gas can reach 10mg/m3 or even below 5mg/m3, and the dust collection performance has nothing to do with the dust characteristics, Wet electrostatic precipitator company It is suitable for the treatment of wet flue gas, especially for the treatment of dusty flue gas after wet desulfurization in power plants and steel plants. However, the equipment investment cost is high, and it needs to be used together with other dedusting equipment. Its investment, technical economy and operating cost should be evaluated from an overall perspective.

Main working principles of wet electrostatic precipitator: large Wet electrostatic precipitator Spray the water mist to the discharge electrode and corona area, the water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode, and the collision interception, adsorption and coagulation of electric field force and charged water mist will jointly trap the dust particles, and finally the dust particles will reach the dust collector under the drive of electric field force and be trapped. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, Qiannan Wet electrostatic precipitator First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, Wet electrostatic precipitator company Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.

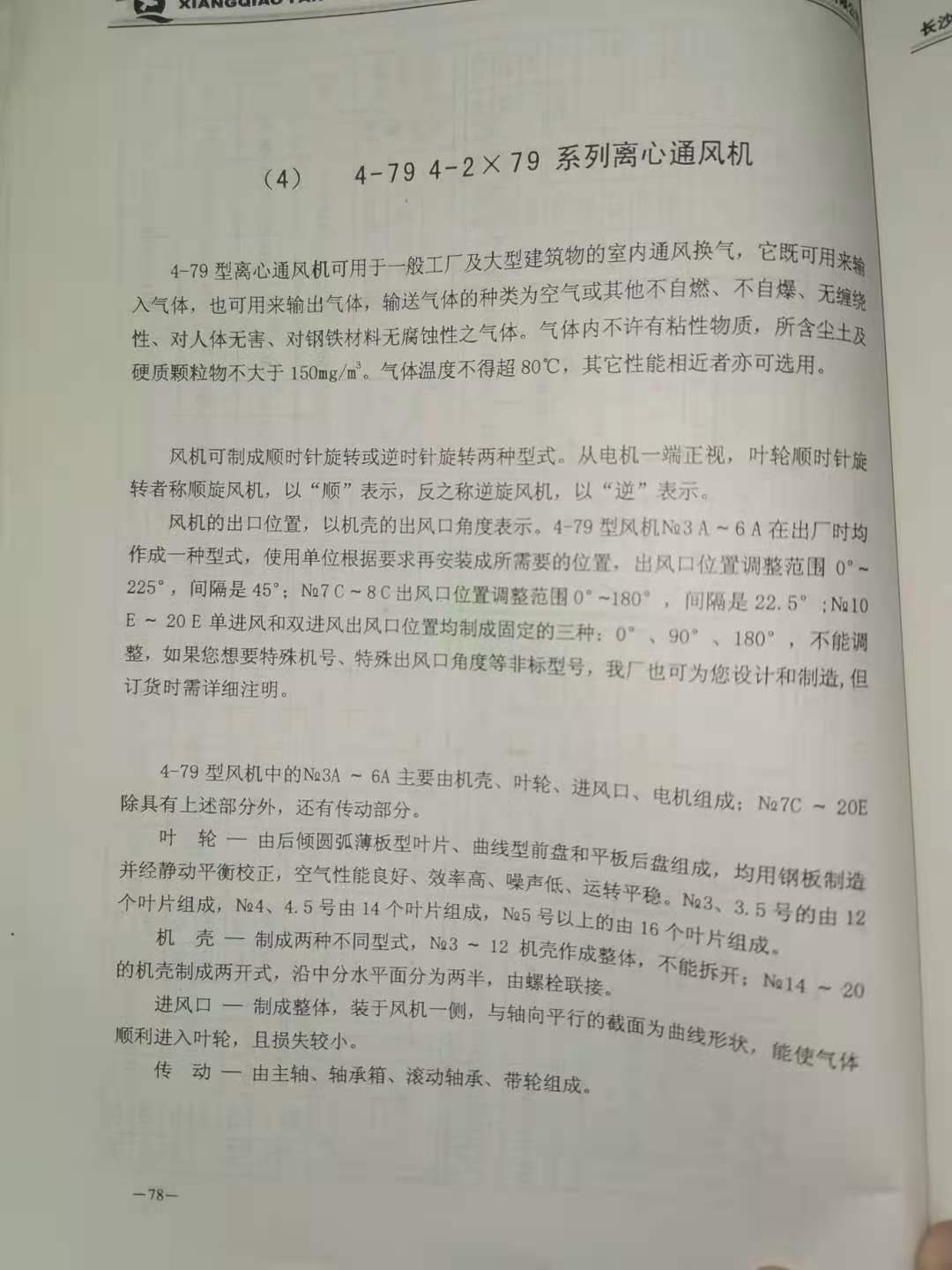

(3) The main faults and causes of the fan may occur during the operation of the fan. For the faults generated, the causes must be quickly identified and solved in time to prevent accidents. Faults in the Operation of 4-72-12 Centrifugal Fan and the Causes Table Fault Name Causes Severe Vibration of Bearing Box 1. The fan shaft is different from the motor shaft, and the coupling is installed askew. 2. The casing or air inlet rubs with the impeller. 3. The foundation stiffness is not enough or firm. 4. Impeller rivet is loose or wheel disc is deformed. 5. The impeller shaft disk and shaft are loose, and the coupling bolt is movable. 6. The connection between casing and bracket, bearing box and bracket, bearing box and seat is loose. 7. The air inlet and outlet pipes of the fan are poorly installed, causing vibration. 8. The rotor is unbalanced. Bearing temperature rise is too high 1. The bearing box vibrates violently. 2. The lubricating grease is poor in quality, deteriorated or overfilled, or contains dust, sand, dirt and other impurities. 3. The tightening force of connecting bolts of bearing cover seat is too large or too small. 4. The shaft and rolling bearing are installed askew, and the front and rear bearings are not concentric. 5. The rolling bearing is damaged. The motor current is too high and the temperature rise is too high. 1. The throttle valve in the air inlet pipe is not closed tightly when driving. 2. The flow exceeds the specified value, or the air duct leaks. 3. The gas density conveyed by the fan is too high. 4. The input voltage of the motor is too low or the power supply is cut off individually. 5. The coupling is improperly connected, the leather ring is too tight or the gap is uneven. 6. Affected by the violent vibration of the bearing box. 7. Affected by deterioration or failure of parallel fans. When the belt slides down, the two pulleys are not in the same plane with each other. Belt runout The distance between two pulleys is too close or the belt is too long.