Correct maintenance is an important guarantee for the safe and reliable operation of the fan and the improvement of its service life. Therefore, Wet dedusting equipment company When using fans, full attention must be paid. Impeller maintenance: at the initial stage of impeller operation and during all regular inspections, whenever there is an opportunity, the impeller must be checked for cracks, wear, dust and other defects. The impeller must be kept clean whenever possible, customized Wet dedusting equipment The steel wire brush shall be used regularly to remove the dust and rust on the impeller. As the travel time increases, the dust can not be evenly attached to the impeller, which will cause damage to the balance of the impeller and even cause rotor vibration. As long as the impeller is repaired, it needs to be dynamically balanced again. If possible, the portable trial dynamic balancing instrument can be used for on-site balancing. Before dynamic balancing, check whether all fastening bolts are tightened. Since the impeller has been operating in an unbalanced state for a period of time, these bolts may have become loose. Bearing maintenance: frequently check the oil supply of bearing lubricating oil. If the box leaks oil, tighten the bolts of the end cover a little. If this is not enough, you may have to use new sealing packing. When the bearing lubricating oil is in normal use, it should be replaced at least once every six months. When it is used for the first time, it should be done after 200 hours of operation. The second oil change should be done in 1 to 2 months. After that, the lubricating oil should be checked once a week. If the lubricating oil does not deteriorate, the oil change can be extended to 2 to 4 months. The specified brand of lubricating oil (specified on the general drawing) must be used when replacing, The old oil in the oil tank shall be completely drained and cleaned before new oil can be filled. If the fan bearing needs to be replaced, pay attention to the following matters: before installing the new bearing, the bearing and bearing box must be very clean. Place the bearing in the oil with a temperature of about 70~80 ℃ and heat it before installing it on the shaft. Do not force assembly to avoid damaging the shaft. Maintenance of other supporting equipment: see the respective user manual for the maintenance of various supporting equipment, including motors, electric actuators, instruments, meters, etc. These operating instructions are provided by each supporting manufacturer. The manufacturer will pack these instructions together and provide them to the user

The operating principle of wet electrostatic precipitator is different from other equipment. The dusty gas enters the expanded ash hopper of the wet electrostatic precipitator for pre collection, and is evenly distributed between each filter bag through the guide plate. The dust is retained on the surface of the filter bag. In order to make the equipment resistance not exceed 1200pa, the high-pressure gas will pulse through the electromagnetic pulse valve, so that the compressed air in the air bag will be ejected from the nozzle hole (called primary air) The surrounding air (called secondary air), which is several times of the primary air, is induced through the venturi to enter the filter bag to make the filter bag expand rapidly in an instant, and shake off the dust with the reverse effect of the air flow to reach the purpose of ash removal. The microcomputer automatic control device is used to adjust the ash cleaning cycle and pulse spraying time randomly according to the dust concentration, so that the dust collector can operate within the resistance range. When changing the bag of the wet electrostatic precipitator, open the top bag changing cover and directly pull out the filter bag, which is simple and convenient to protect. Guangdong customized Wet dedusting equipment Wet electrostatic precipitators are mostly used in bag type precipitators. Dust removal bags are installed in the gas box. Wet electrostatic precipitators are mostly external filter type. Dust is collected in the ash hopper of wet electrostatic precipitators through the injection of pulse solenoid valves. The wet electrostatic precipitator is installed in a simple structure. This device is planned as an internal filtering structure, which can change the external pressure of the wet electrostatic precipitator to the internal pressure. In this way, the shell of the wet electrostatic precipitator can be structured without external iron plate sealing, which saves costs and does not hinder the use of the wet electrostatic precipitator. The processing of wet electrostatic precipitator is particularly important. In recent years, some Wet dedusting equipment company Small manufacturers use small sewing machines as processing equipment, and use low-quality thread as raw materials during processing, which is fake, and the processing level is far behind. The wet electrostatic precipitator will open lines, cracks, and drop the bottom after a short time of operation. Although the size of the cloth bag is slightly smaller, it can also be used, but after absorbing the dust with large specific gravity, the bag will drop after a period of use.

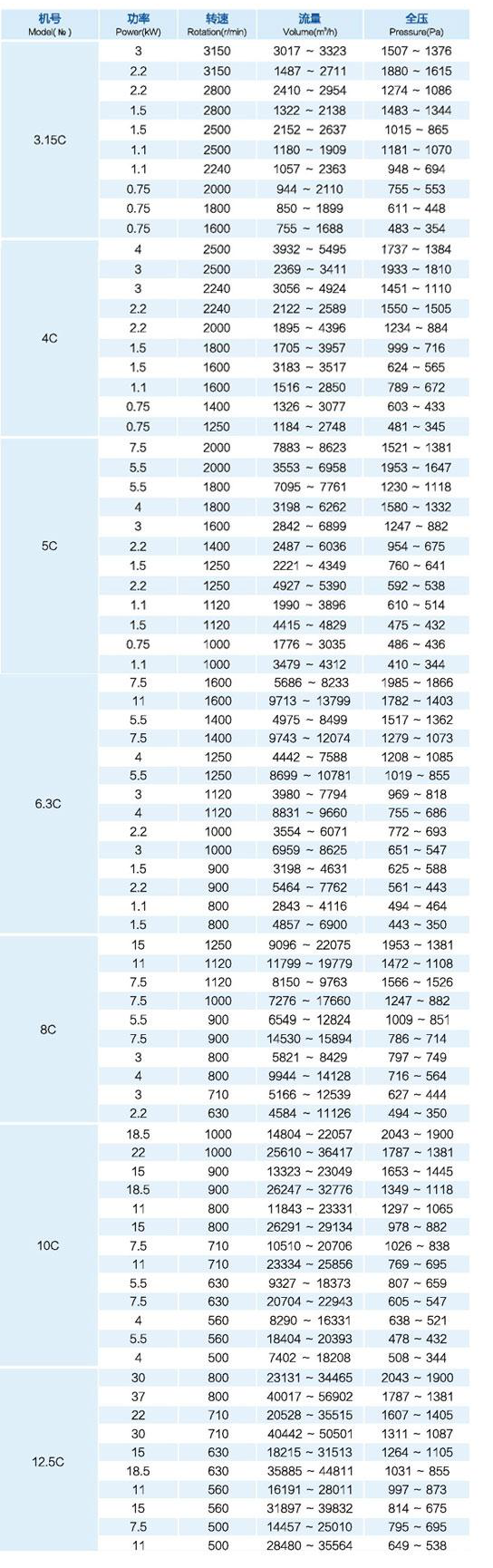

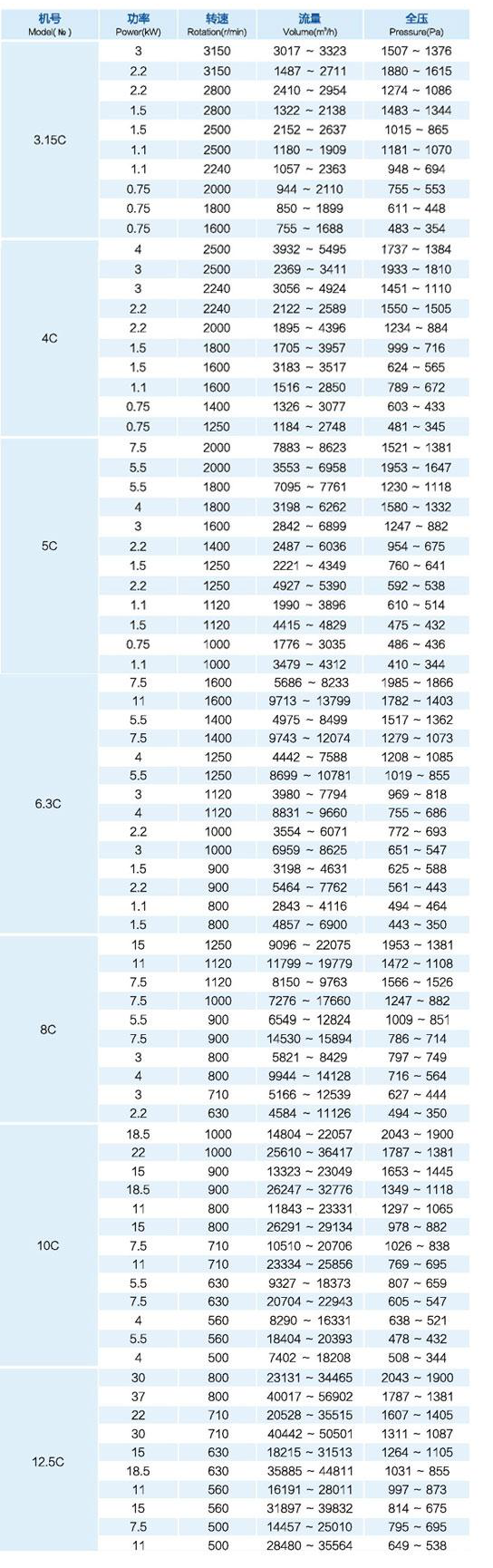

2. The influence of the total pressure deviation Δ H of the fan itself was not considered during selection. When the actual total pressure of the fan was positive deviation, the flow increased; When the actual total pressure of the fan is negative deviation, the flow decreases. See (a) below. The relationship between the deviation of the pipe network characteristic curve and the total pressure and the flow can be eliminated by one of the following methods when the fan starts to officially operate after new installation, or when the flow is too large or too small during use. 1. Use the opening and closing of throttling device to adjust the flow. 2. Increase or decrease the flow by increasing or decreasing the fan speed. 3. Use a new fan with higher or lower pressure to increase or decrease the flow. 4. Change the pipe network to reduce the resistance coefficient of the pipe network to increase the flow. It must be pointed out that throttling devices are generally used to regulate the flow. However, when the actual flow is much larger than the required flow, this method wastes too much power and is very uneconomical. If conditions permit, the fan speed is usually reduced or the fan with lower pressure is replaced. When the throttling device is fully open, the flow is still too small. At this time, the throttling device has lost its function, so try to reduce the resistance coefficient of the pipe network to increase the flow, or increase the fan speed and replace the fan with higher pressure. However, the speed of the fans directly connected to the motor and the coupling cannot be changed generally. Only the fan driven by the pulley can increase or decrease the speed by changing the diameter of the pulley, but the speed of the fan cannot exceed the speed max in the performance and selection table.

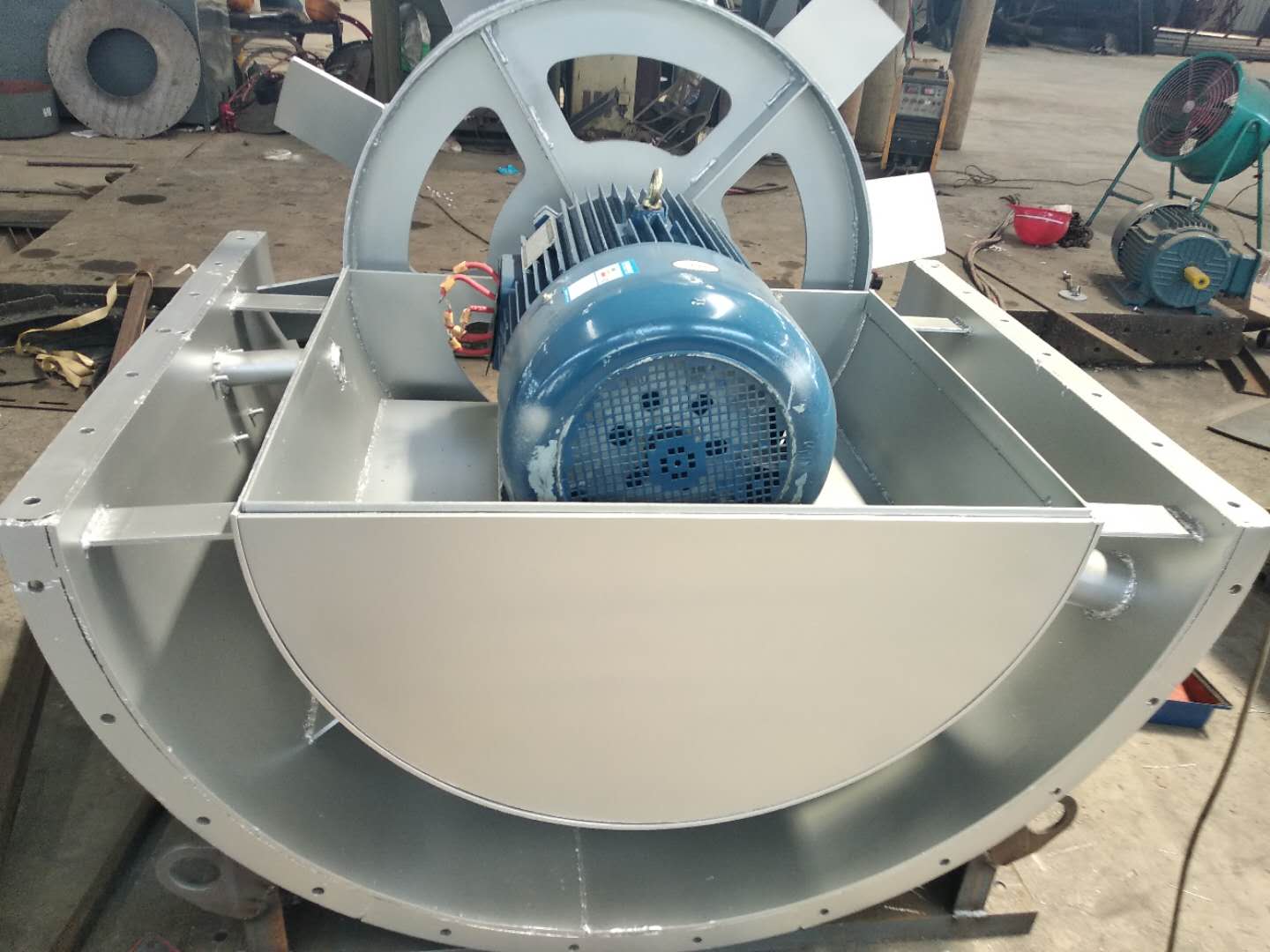

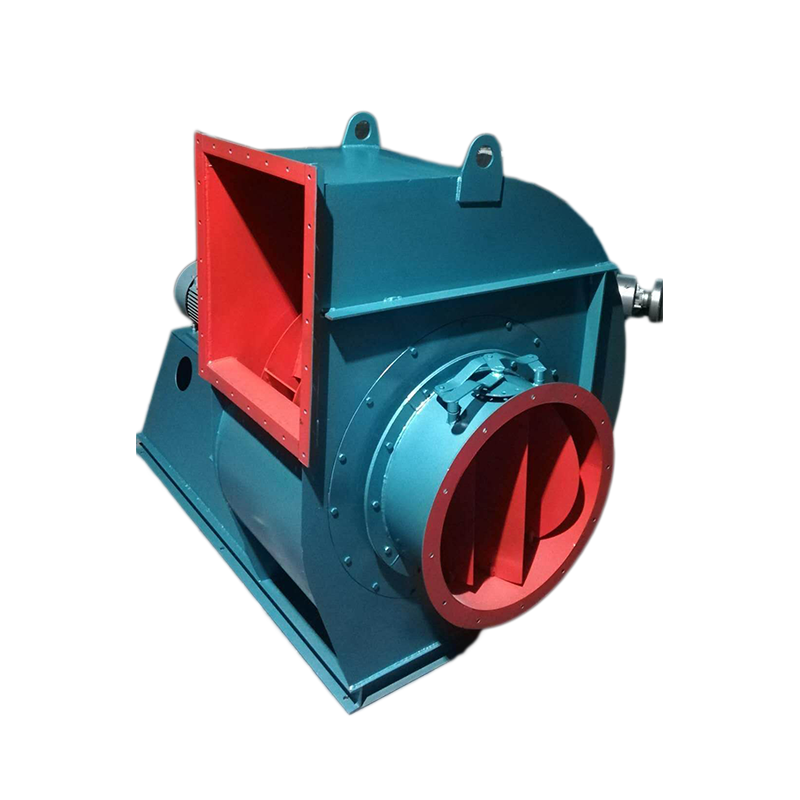

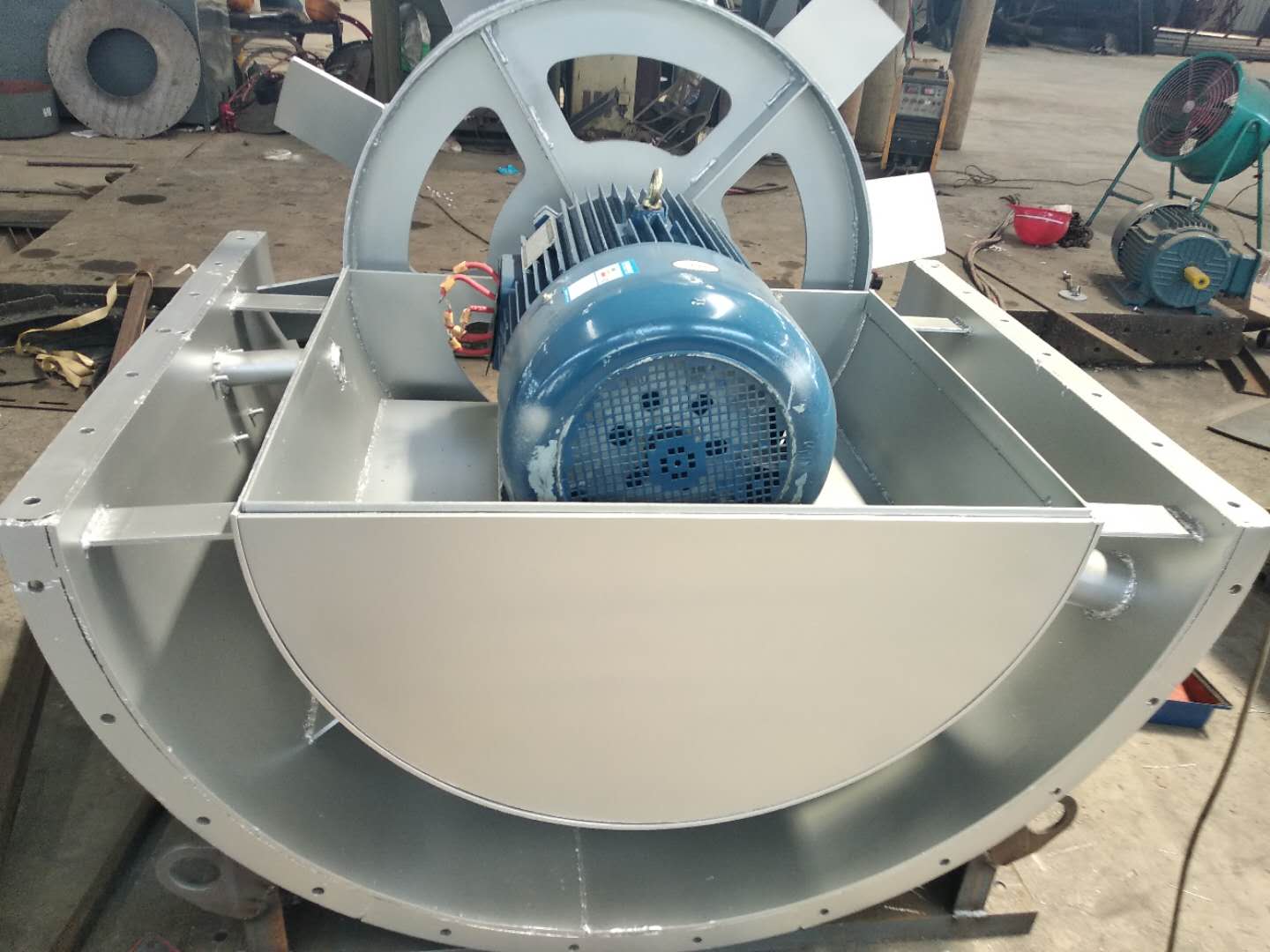

customized Wet dedusting equipment The fan is a kind of driven fluid machinery, which relies on the input mechanical energy to increase the gas pressure and discharge gas. Fan is the abbreviation of Chinese custom for gas compression and gas transmission machinery. Generally speaking, fans include fans, blowers, and wind turbines. Guangdong Wet dedusting equipment company Fans are widely used for ventilation, dust discharge and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings, as well as ventilation and induced draft of boilers and industrial furnaces; Cooling and ventilation in air conditioning equipment and household appliances; Drying and delivery of grain, wind source of wind tunnel and inflation and propulsion of hovercraft

3. When installing Type C and Type B, ensure that the two pulley positions are on the same plane, and the flatness tolerance is 0.5mm. 4. When installing Type D, use a dial indicator and feeler gauge to measure the coaxiality of the fan spindle and motor spindle and the parallelism of both ends of the coupling. The coaxiality tolerance of two shafts is 0.2mm, the parallelism tolerance of both ends of the coupling is 0.2mm, and the spacing between two planes of the coupling is 5 to 8mm. 5. After the fan is installed, move the rotor with hand or lever to check whether it is too tight or collided. The test run can be carried out without overtightening or collision. 6. After the motor is installed, the belt pulley or coupling guard shall be installed. If the air inlet is not connected to the air inlet pipe, the guard net or other safety devices (provided by the user) shall also be provided. 7. Other parts shall be installed according to the corresponding positions in the drawing. 8. Add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window.

Guangdong customized Wet dedusting equipment Installation requirements a. The foundation of the fan shall be level and solid, and the foundation height shall be ≥ 200mm. b、 The fan and air duct shall be connected by flexible hose (flexible material and non combustible), the length shall not be less than 200mm, and the pipe diameter shall be the same as the inlet and outlet size of the fan. In order to ensure that the hose will not be twisted or deformed during the system operation, it should be installed with appropriate tightness. The canvas hose installed at the suction end of the fan can be slightly tightened to prevent the fan from being sucked in during operation and reduce the sectional size of the canvas hose. c、 Wet dedusting equipment company The steel support of the fan must be fixed on the concrete foundation, and a rubber damping pad must be added between the steel support of the fan and the foundation. All fan and motor components are installed on the whole steel support, and the steel ground frame is installed on the damping pad at the top of the foundation. The damping pad is preferably made of perforated rubber plates. d、 The pipe diameter at the outlet of the fan can only be increased, but not decreased. At the end of the outlet, an insect screen should be installed. When the fan is inclined to the upper outlet, a rain cap should be added