Main working principles of wet electrostatic precipitator: major Wet dust collector Spray the water mist to the discharge electrode and corona area, the water mist will split and further atomize after being charged in the powerful corona field formed by the barbed electrode, and the collision interception, adsorption and coagulation of electric field force and charged water mist will jointly trap the dust particles, and finally the dust particles will reach the dust collector under the drive of electric field force and be trapped. The water forms a continuous water film on the dust collecting electrode, and the captured dust is washed into the ash hopper and discharged with water. Operating principle of wet electrostatic precipitator. The dedusting process of electrostatic precipitator can be divided into four stages: gas ionization; The dust is charged with ions; Charged dust moves towards the electrode; Remove the dust on the electrode. Only the objects removed by wet electrostatic precipitation are dust and droplets, but their working principles are different due to the differences in physical characteristics between droplets and dust. In principle, Auspicious head Wet dust collector First of all, the existence of water droplets has an impact on the electrode discharge. To form emitting ions, free electrons in the metal electrode must obtain enough energy to overcome the ionization energy and cross the surface barrier to become emitting electrons. It is an effective measure to reduce the surface barrier by bringing water on the electrode surface. After the metal surface is covered with water, the original "metal air" interface is divided into "metal water" interface and "water air" interface. The potential barrier of the latter two interfaces is much lower than that of the former interface. In this way, after the metal surface is filled with water, the original high barrier will be divided into two low barriers, which will greatly weaken the blocking effect of the surface barrier on free electrons and make electrons easy to launch. In addition, Wet dust collector manufactor Under the action of electric field, various impurity ions in water can easily cross the surface barrier and become emission ions. All of these have changed the electrode discharge effect, enabling corona discharge under low voltage. Secondly, due to the existence of water droplets, the resistance of water is relatively small. When water droplets combine with dust, the specific resistance of dust with high specific electricity decreases, so the working state of wet electrostatic precipitator will be more stable; In addition, since the wet electrostatic precipitator is washed by water flow and has no rapping device, it will not produce secondary dust.

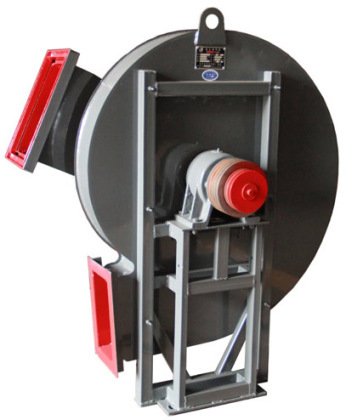

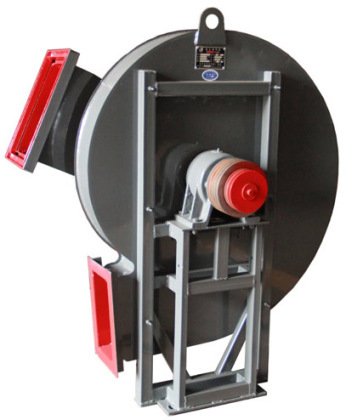

major Wet dust collector Fans can be divided into axial flow fans, centrifugal fans and diagonal flow (mixed flow) fans according to the flow direction after the airflow enters the impeller. Fans are divided into press in local fans (hereinafter referred to as press in fans) and flame-proof motors placed outside or inside the flow channel, and flame-proof motors placed inside the explosion-proof sealing chamber of the extraction type local fans (hereinafter referred to as extraction fans) according to their purposes. Wet dust collector manufactor Fans can also be divided into single-stage, two-stage or multi-stage pressurization fans according to the form of pressurization. For example, 4-72 is single-stage pressurization, and high-end fan is multi-stage pressurization fan. Fans can be divided into axial flow fans, mixed flow fans, roof fans, air conditioning fans, etc. Fan can be divided into negative pressure fan, low pressure fan, medium pressure fan and high pressure fan according to pressure. According to the outlet pressure (pressure rise), it can be divided into: ventilator (≤ 15000 Pa), blower (15-350000 Pa), compressor (≥ 350000 Pa)

In order to avoid man-made faults and accidents caused by improper maintenance, prevent the occurrence of natural faults and accidents of fans and motors in all aspects, so as to give full play to the efficiency of equipment and extend the service life of equipment, therefore, the maintenance of fans must be strengthened. (1) Working system of fan maintenance The fan maintenance personnel must pay attention to the following points: 1. The fan can only be operated when the fan equipment is completely normal. 2. If the fan equipment starts after maintenance, pay attention to whether all parts of the fan are normal. 3. Regularly clean the dust, dirt, water and other impurities inside the fan and gas transmission pipeline, and check whether the impeller is worn and rusted, if any, repair and replace it in time. 4. Regularly replace the lubricating oil (recommended 3-6 months). It is recommended to add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window. 5. Regularly check (3-6 months is recommended) couplings, pulleys, etc. If parts are found to be worn or rusted, they should be repaired and replaced immediately. 6. The equipment shall not be repaired during operation.

Wet dust collector manufactor The work starts before the fan is used. one Auspicious head Wet dust collector manufactor Carefully read the fan operation instructions and product samples, and be familiar with and understand the fan specifications, forms, impeller rotation direction and air flow in and out direction; Check whether all parts of the fan are in good condition again, or they can be installed and used only after being repaired. 2. The fan must be installed with safety devices to prevent accidents, and installed and wired by professionals familiar with relevant safety requirements. 3. The air duct connecting the inlet and outlet of the fan has separate support, and it is not allowed to add the overlapping weight of the duct to the components of the fan; When installing the fan, pay attention to the horizontal position of the fan, and adjust the connection between the joint surface of the fan and the foundation and the air outlet pipe to make it coincide naturally. Forced connection is not allowed. four major Wet dust collector After the fan is installed, move the impeller by hand or lever to check whether it is too tight or rubbed, and whether there is any object that hinders the rotation. The test run can be carried out only when there is no abnormal phenomenon. The exposed part of the fan transmission device should be equipped with a protective cover (provided by the user). If the fan inlet is not connected, a protective screen or other installation device (provided by the user) should also be added. 5. The power distribution control box of the fan must match the corresponding fan (power, voltage, pneumatic mode, control mode, etc.). 6. The fan wiring should be made by a professional electrician, and the wiring must be correct and reliable. Especially, the wiring number at the electric control box should be consistent with the number on the fan terminal. The fan shell should be reliably grounded. The grounding must be reliable, and zero connection cannot be used instead of grounding. 7. After all fans are installed, check whether there are any left tool box sundries inside the fan