Emergency stop: customized Boiler centrifugal fan Price In case of one of the following situations during the unit commissioning, emergency shutdown shall be carried out immediately. The emergency stop operation is to press the stop button of the main motor, and then carry out the remedial work after the shutdown; The centrifugal fan suddenly vibrates strongly and has exceeded the trip value; There is scratch or abnormal friction sound inside the machine body; customized Boiler centrifugal fan Smoke occurs at any bearing or seal, or the temperature of a bearing rises sharply to the alarm value; When the oil pressure is lower than the alarm value and cannot be restored to normal; The liquid level in the oil tank is low, and there is suction phenomenon; When the axial displacement value increases significantly and reaches the alarm value;

Preparations for fan installation. customized Boiler centrifugal fan Before unpacking the fan, check whether the package is intact, whether the nameplate parameters of the fan meet the requirements, and whether all accompanying accessories are complete. Carefully check whether the fan is deformed or damaged during transportation, whether the fasteners are loose or fall off, and whether the impeller is scratched, and check all parts of the fan. Shiyan Boiler centrifugal fan Price If any abnormality is found, it shall be repaired before use. Use a 500V megger to measure the insulation resistance between the fan housing and the motor winding. The value should be greater than 0.5 megohm. Otherwise, the motor winding should be dried. The temperature during drying should not exceed 120 ℃. Prepare various materials, tools and sites required for fan installation.

The use of wet electrostatic precipitators is becoming more and more common. How much do you know about the equipment? Today, I'm going to popularize knowledge for you and talk about the advantages and disadvantages of wet electrostatic precipitator. Let's learn together. Advantages of electrostatic precipitator High purification efficiency, capable of spreading fine particles of more than 0.01 microns. In the design, different operating parameters can be used to meet the required purification efficiency. ⑵ The resistance loss is small, generally below 20 mm water column. Compared with cyclone dust collector, the total power consumption is small even considering the power consumption of power supply unit and rapping mechanism. ⑶ Shiyan Boiler centrifugal fan The allowable operating temperature is high. For example, the allowable operating temperature of SHWB type circuit dust collector is 250 ℃. Other types can reach 350~400 ℃ or higher. ⑷ Large gas processing range. ⑸ customized Boiler centrifugal fan Automatic operation control can be fully realized. Disadvantages of electrostatic precipitator The equipment is relatively complex, requiring a high level of equipment allocation, installation and maintenance management. ⑵ There are certain requirements for the specific resistance of dust, so there is a certain selectivity for dust, which can not make all dust obtain high purification efficiency. ⑶ It is greatly affected by the operating conditions such as air temperature and temperature. If the same kind of dust is operated at different temperatures and humidities, the results will be different. Some dust can work well at a certain temperature and humidities, but the ESP can hardly be used at another temperature and humidities due to the change of dust resistance. ⑷ Boiler centrifugal fan Price The primary investment is large, and the horizontal electrostatic precipitator covers a large area. ⑸ At present, the practical effect in some enterprises can not meet the design requirements.

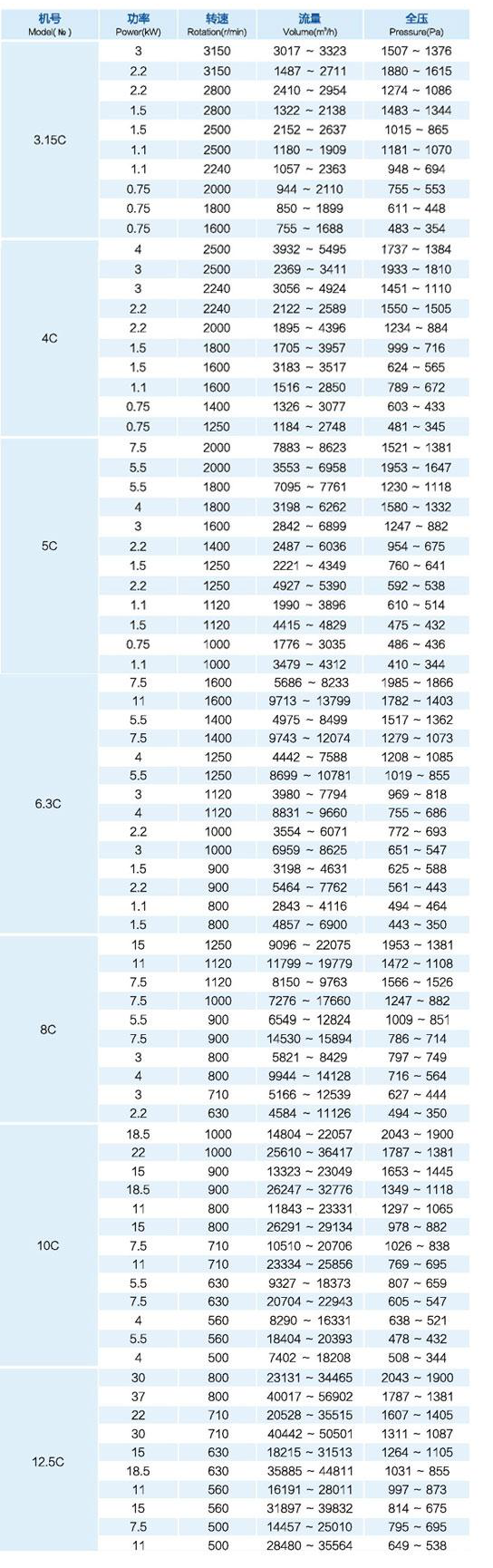

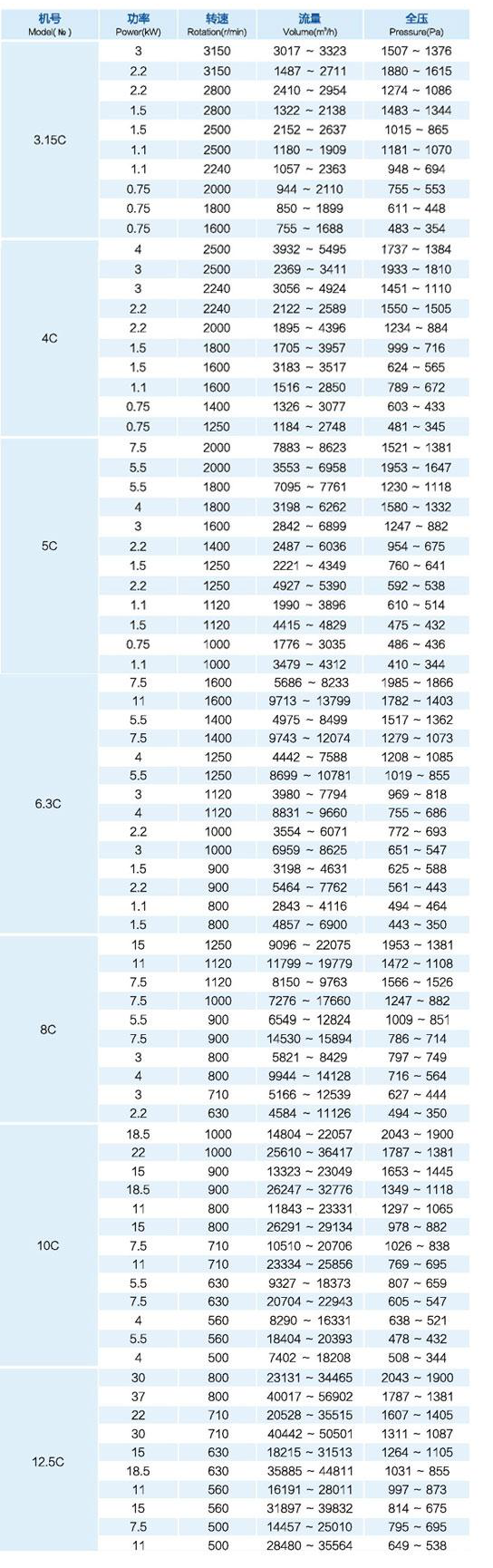

The selection of fans Product performance and fan performance listed in the selection table are based on the performance of delivering air under standard conditions. Therefore, when the use condition is non-standard, the H4-72-12 centrifugal fan must convert the use performance into the performance under standard conditions according to the relationship in the table above, and then select according to the performance and selection table. (3) Treatment of excessive or insufficient flow During use, excessive or insufficient flow often occurs. There are many reasons for this phenomenon. If the flow is high and low during use, it is mainly because the resistance in the pipe network is high and low, or the fan works in a non working area. If it is gradually reduced after a long time during use, it is mainly due to pipe network blockage. After the fan is newly installed, the flow is too large or insufficient during the formal operation. The main reasons for this phenomenon are as follows: 1. The actual value of pipe network resistance is too different from the calculated value. In the general pipe network characteristic equation, H=KQ2, if the actual value K of K-resistance coefficient is less than the calculated value K, the flow will increase; If the actual value K is greater than the calculated value K, the flow decreases. See (b) below.