customized Boiler fan The wet electrostatic precipitator mainly has two structural forms. One is to use corrosion-resistant conductive materials (which can be non-metallic materials with excellent conductivity or metal materials with corrosion-resistant characteristics) as the dust collector, and the other is to use non-conductive non-metallic materials as the dust collector by forming a conductive water film through water spray or overflow. Wet electrostatic precipitators can also be divided into cross flow type (horizontal) and vertical flow type (vertical) according to the flow direction of waste gas. The cross flow type is mostly plate structure, Xiangxiang Boiler fan The gas flows in and out in the horizontal direction, and the structure is similar to the dry electrostatic precipitator; The vertical flow type is mostly tubular structure, and the gas flow direction is vertical. Generally speaking, the efficiency of vertical flow wet electrostatic precipitator is twice as high as that of cross flow wet electrostatic precipitator under the condition of the same ventilation cross-sectional area. The dust deposited on the electrode plate can be washed down by water. Wet dust removal can avoid the re flying of captured dust and achieve high dust removal efficiency. Since there is no rapping device, the operation is also more reliable. The device that forms conductive film on the surface of the dust collector by means of water spray or overflow water has problems of corrosion, sludge and sewage treatment. It is only used when the dust concentration of the gas is low and the dust removal efficiency is required to be high; The wet electrostatic precipitator using corrosion-resistant conductive materials as dust collector does not need long-term water spraying or overflow water, Boiler fan manufactor Regular flushing is only carried out according to the operating conditions of the system, and only a small amount of water is consumed. This part of water can be recycled, and the dust collection system is basically free of secondary pollution.

customized Boiler fan The reasons for failure caused by unstable operation are: improper temperature control of insulator box; The gas distributor grid is blocked, and the sediment electrode has too thick scale; Improper adjustment of water film; The oxygen content in the system exceeds the standard. ① Insufficient steam pressure and blocked steam pipeline may cause low temperature of insulator box. In the long run, the insulator surface temperature is low, and tar and dust particles accumulate, causing electric field short circuit. If the temperature of insulator box rises too fast, or the temperature changes violently during operation, the insulator will be cracked. ② Boiler fan manufactor If intermittent flushing cannot be carried out as required during operation, the tar accumulated on the sediment pipe wall is difficult to be thoroughly cleaned, which, accumulated over time, not only causes excessive resistance to equipment operation, but also leads to damage to the electric field. ③ During maintenance, the water film is not adjusted as required, the water film is uneven or not thick enough, and after putting into operation, the phenomenon described in fault (4) will occur. The above situation also occurs when the water film is damaged during operation. ④ The reason for the explosion of the electrostatic precipitator is that the oxygen content in the gas exceeds the standard, the mixed explosive gas is formed in the equipment and reaches the explosion limit, and the explosion occurs when encountering electric sparks.

2. The influence of the total pressure deviation Δ H of the fan itself was not considered during selection. When the actual total pressure of the fan was positive deviation, the flow increased; When the actual total pressure of the fan is negative deviation, the flow decreases. See (a) below. The relationship between the deviation of the pipe network characteristic curve and the total pressure and the flow can be eliminated by one of the following methods when the fan starts to officially operate after new installation, or when the flow is too large or too small during use. 1. Use the opening and closing of throttling device to adjust the flow. 2. Increase or decrease the flow by increasing or decreasing the fan speed. 3. Use a new fan with higher or lower pressure to increase or decrease the flow. 4. Change the pipe network to reduce the resistance coefficient of the pipe network to increase the flow. It must be pointed out that throttling devices are generally used to regulate the flow. However, when the actual flow is much larger than the required flow, this method wastes too much power and is very uneconomical. If conditions permit, the fan speed is usually reduced or the fan with lower pressure is replaced. When the throttling device is fully open, the flow is still too small. At this time, the throttling device has lost its function, so try to reduce the resistance coefficient of the pipe network to increase the flow, or increase the fan speed and replace the fan with higher pressure. However, the speed of the fans directly connected to the motor and the coupling cannot be changed generally. Only the fan driven by the pulley can increase or decrease the speed by changing the diameter of the pulley, but the speed of the fan cannot exceed the speed max in the performance and selection table.

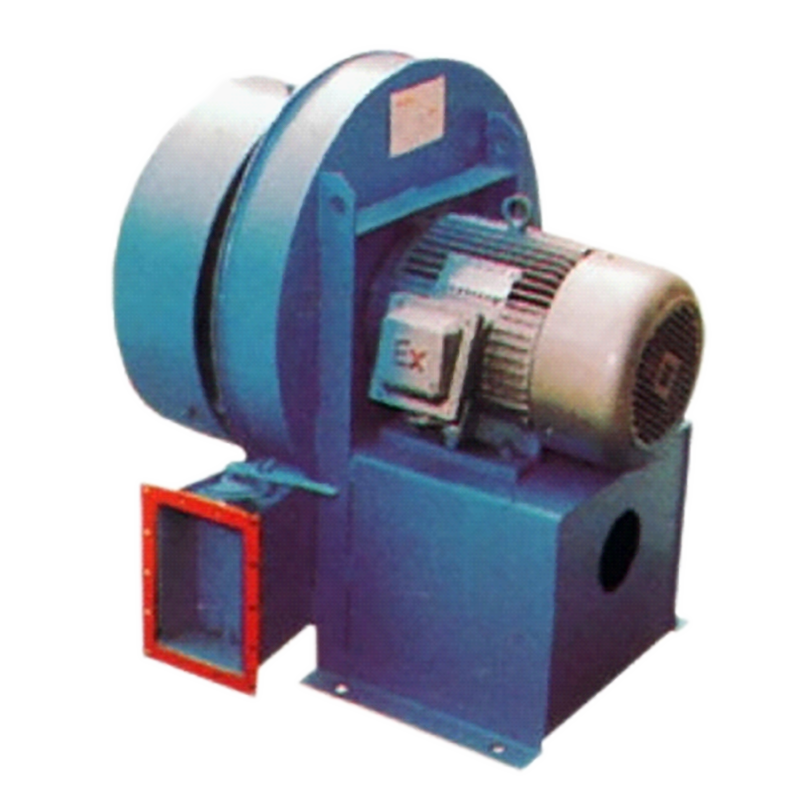

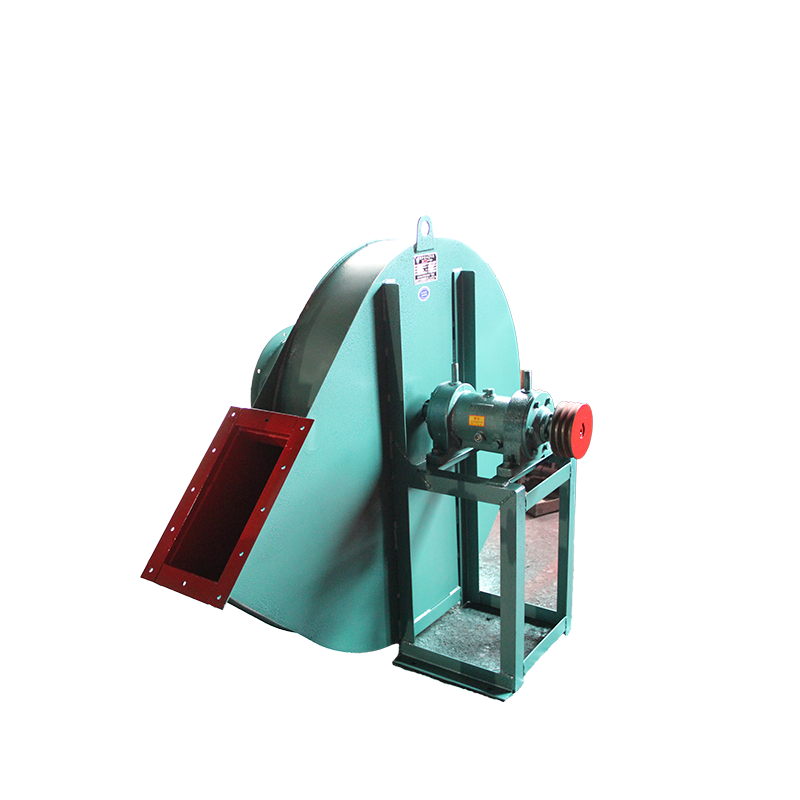

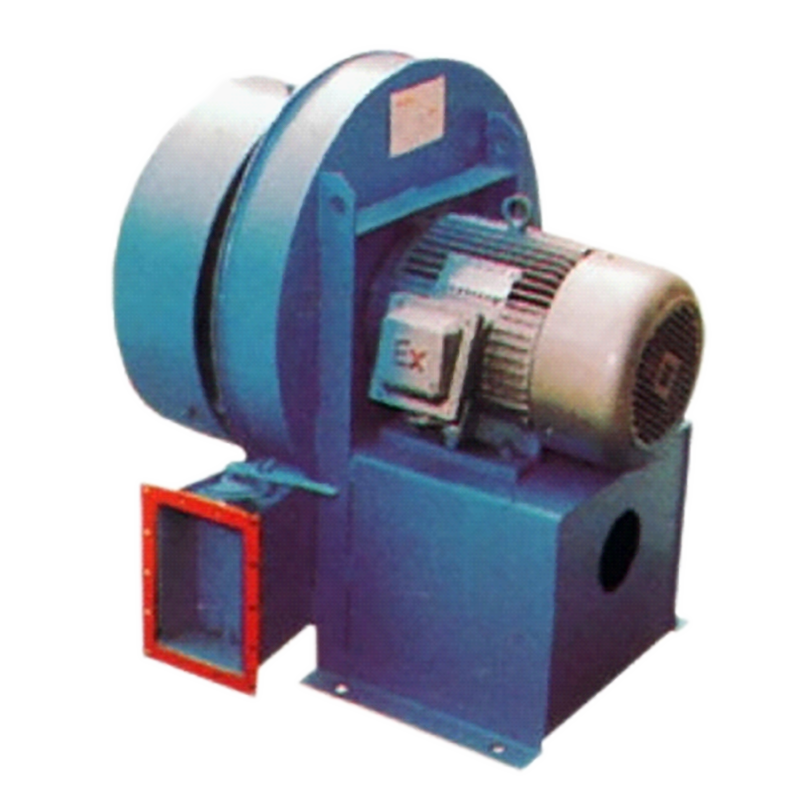

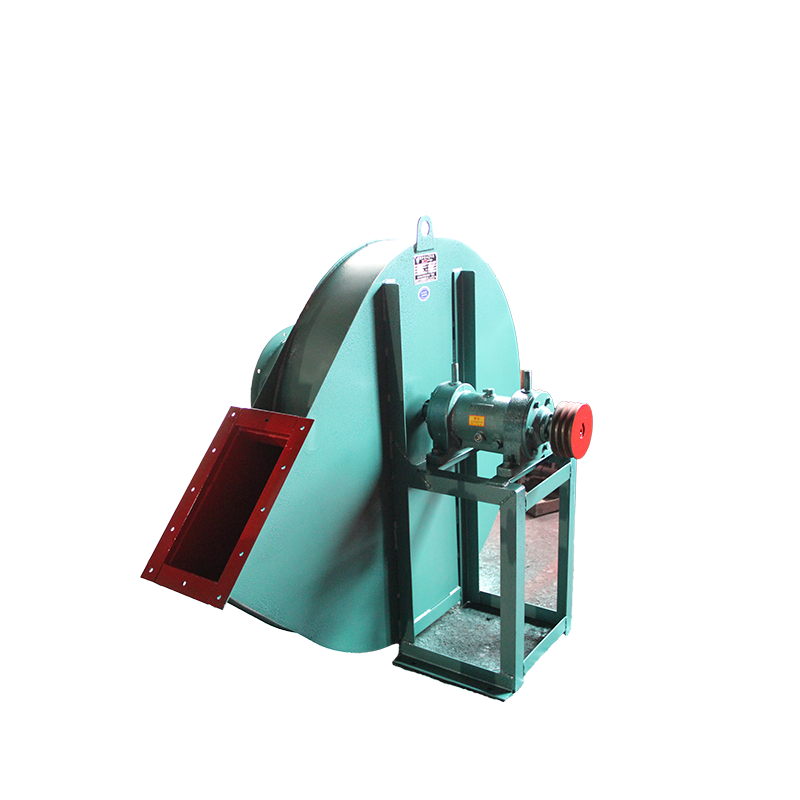

Fans can be classified into several types according to the materials used, such as iron shell fans (ordinary fans), glass fiber reinforced plastic fans, plastic fans, aluminum fans, stainless steel fans, etc. Boiler fan manufactor In the direction of gas flow. Fans can be classified into centrifugal, axial, diagonal (mixed flow) and cross flow fans according to the direction of gas flow. (1) Centrifugal fan. The airflow enters the impeller of the fan axially and flows mainly along the radial direction. This type of fan is made according to the principle of centrifugal action, and its products include centrifugal fan, centrifugal blower and centrifugal compressor. (2) Axial flow fan. The airflow enters the impeller of the fan axially and flows approximately along the axis on the cylindrical surface. Such fans include axial fans, axial blowers and axial compressors. (3) Rotary fan. Xiangxiang customized Boiler fan Use the rotor rotation to change the air chamber volume to work. Common varieties include Roots blower and rotary compressor.

Emergency stop: customized Boiler fan manufactor In case of one of the following situations during the unit commissioning, emergency shutdown shall be carried out immediately. The emergency stop operation is to press the stop button of the main motor, and then carry out the remedial work after the shutdown; The centrifugal fan suddenly vibrates strongly and has exceeded the trip value; There is scratch or abnormal friction sound inside the machine body; customized Boiler fan Smoke occurs at any bearing or seal, or the temperature of a bearing rises sharply to the alarm value; When the oil pressure is lower than the alarm value and cannot be restored to normal; The liquid level in the oil tank is low, and there is suction phenomenon; When the axial displacement value increases significantly and reaches the alarm value;

Xiangxiang Boiler fan manufactor The development trend and direction of wind turbine in the future are analyzed as follows: wind turbine is mainly used for ventilation and air exchange in various fields of national economy and various places, such as metallurgy, petrochemical, electric power, urban rail transit, textile, shipbuilding, etc. In addition to the traditional application fields, there will still be great development prospects in more than 20 potential market fields, such as comprehensive utilization of coal gangue, new dry process clinker technology, energy saving in metallurgical industry and comprehensive utilization of resources. customized Boiler fan With the increasing competition in the wind turbine manufacturing industry, mergers and acquisitions and capital operations among large wind turbine manufacturing enterprises are becoming increasingly frequent. Domestic outstanding wind turbine manufacturing enterprises are increasingly paying attention to the research of the industry market, especially the in-depth research of the industry development environment and product buyers. Because of this, a large number of domestic excellent fan brands have risen rapidly and become the leaders in the fan manufacturing industry!