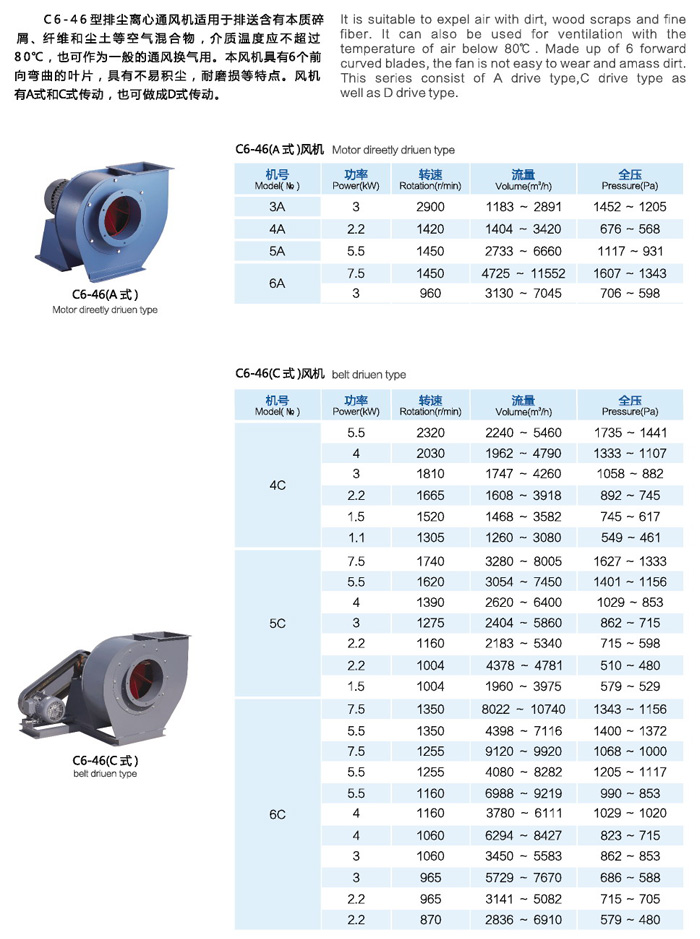

Xiangyang Axial flow centrifugal fan manufactor The development trend and direction of wind turbine in the future are analyzed as follows: wind turbine is mainly used for ventilation and air exchange in various fields of national economy and various places, such as metallurgy, petrochemical, electric power, urban rail transit, textile, shipbuilding, etc. In addition to the traditional application fields, there will still be great development prospects in more than 20 potential market fields, such as comprehensive utilization of coal gangue, new dry process clinker technology, energy saving in metallurgical industry and comprehensive utilization of resources. customized Axial flow centrifugal fan With the increasing competition in the wind turbine manufacturing industry, mergers and acquisitions and capital operations among large wind turbine manufacturing enterprises are becoming increasingly frequent. Domestic outstanding wind turbine manufacturing enterprises are increasingly paying attention to the research of the industry market, especially the in-depth research of the industry development environment and product buyers. Because of this, a large number of domestic excellent fan brands have risen rapidly and become the leaders in the fan manufacturing industry!

Gas compression and gas transmission machinery is a machine that converts rotating mechanical energy into gas pressure energy and kinetic energy and transports gas. The main structural components of the fan are impeller, casing, air inlet, support, motor, pulley, coupling, silencer, transmission parts (bearings), etc. customized Axial flow centrifugal fan The unpowered fan uses the air thermal convection caused by the natural wind force and the indoor and outdoor temperature difference to drive the turbine to rotate, thus using the centrifugal force and negative pressure effect to exhaust the indoor stale hot air. Xiangyang Axial flow centrifugal fan manufactor The fan is related to the transmission and distribution energy consumption of the system, and is a very critical part of building energy conservation. According to the fan inspection conducted by the National Air Conditioning Equipment Quality Supervision and Inspection Center for many years, many fans have problems under rated conditions, so it is necessary to produce and manufacture fans in strict accordance with product standards. customized Axial flow centrifugal fan At the beginning of the fan operation, the vibration of the bearing is very small, but with the extension of the operating time, the dust in the fan will be unevenly attached to the impeller, gradually destroying the dynamic balance of the fan, making the bearing vibration gradually increase. Once the vibration reaches the maximum allowable value of 11mm/s of the fan (the maximum allowable value expressed by the amplitude value is as follows), The fan must be shut down for repair (dust accumulation shall be removed and dynamic balance shall be redone). Because it is very dangerous at this time, users must not use it forcibly. When the fan vibration is close to the dangerous value, the vibration measuring instrument will give an alarm.

In order to avoid man-made faults and accidents caused by improper maintenance, prevent the occurrence of natural faults and accidents of fans and motors in all aspects, so as to give full play to the efficiency of equipment and extend the service life of equipment, therefore, the maintenance of fans must be strengthened. (1) Working system of fan maintenance The fan maintenance personnel must pay attention to the following points: 1. The fan can only be operated when the fan equipment is completely normal. 2. If the fan equipment starts after maintenance, pay attention to whether all parts of the fan are normal. 3. Regularly clean the dust, dirt, water and other impurities inside the fan and gas transmission pipeline, and check whether the impeller is worn and rusted, if any, repair and replace it in time. 4. Regularly replace the lubricating oil (recommended 3-6 months). It is recommended to add N46 (ISO VG46, 30) in summer and N32 (ISO VG32, 20) in winter. The oil level should be at 1/2 of the oil window. 5. Check the coupling and belt pulley regularly (3-6 months is recommended), and repair and replace them immediately if parts are worn or rusted. 6. The equipment shall not be repaired during operation.

How are dust collectors classified, customized Axial flow centrifugal fan Do you know how to distinguish it and how to define its economic type? Let's talk about it from these aspects. 1. Dust removal efficiency. Xiangyang Axial flow centrifugal fan Dust removal efficiency refers to the ratio of the amount of dust collected by the dust collector to the amount of dust entering the dust collector. According to the total dedusting efficiency, the dedusters can be divided into: low efficiency dedusters (50~80%), medium efficiency dedusters (80~95%) and high efficiency dedusters (more than 95%). 2. Dust removal resistance. The resistance indicates the pressure loss when the airflow passes through the dust remover. According to the resistance, dust collectors can be divided into low resistance dust collectors (Δ P<500Pa), medium resistance dust collectors (Δ P=500 ~ 2000Pa) and high resistance dust collectors (Δ P=2000 ~ 20000Pa). 3. Economy. Economy is one of the important indexes for evaluating dust remover, which includes equipment cost and operation and maintenance cost of dust remover. Among all kinds of dust collectors, the equipment cost of electrostatic precipitator is the highest, followed by bag type dust collector, Venturi tube dust collector, cyclone dust collector is the lowest electrostatic precipitator: the dust removal efficiency is high, generally above 99%, and the design efficiency is up to 99.99%. The wet dust collector is commonly known as "water dust collector" : The filtration efficiency can reach more than 85%, and the integrated desulfurization and dust remover of stone water film+swirl plate>>about 80% of desulfurization and dust removal can reach as high as about 95%.

customized Axial flow centrifugal fan Common fault: the working medium of the fan in the cement industry often contains a certain amount of homogeneous particles with different sizes and shapes, such as the induced draft fan of the dust removal system and the blower for pneumatic conveying. Because these fans work in the dusty air flow, the dust particles in the air flow will not only wear the fan, but also attach ash on the fan blades, and the wear and ash deposition are uneven. As a result, the balance of the fan rotor is destroyed, which causes the fan vibration and shortens the life of the fan. In serious cases, the fan can not work normally. Especially, the fan blades are worn most seriously, Axial flow centrifugal fan manufactor It not only destroys the flow characteristics in the fan, but also easily leads to major accidents such as blade fracture and runaway. The wear of transmission parts is also a common problem of fans, including various shafts, rollers, reducers, motors, pumps and other bearing positions, bearing seats, keyways, threads and other parts. The traditional repair welding machine processing method is easy to cause material damage, resulting in deformation or fracture of parts, with greater limitations; Brush plating and spray re machining methods often require outsourcing, which not only requires long repair cycle and high cost, but also can not fundamentally solve the causes of wear (poor impact resistance and yield of metal) because the repair materials are metal materials; Many parts can only be scrapped and replaced, which greatly increases the production cost and inventory of spare parts, leaving the enterprise's good resource advantage idle and wasted