Here's what Wet dedusting Selection basis of the device.

Dust removal efficiency. The efficiency of wet dust collector is the most important index in its selection. The flow of gas in a certain state is a specific dust pollutant. The state of the gas directly affects the collection efficiency.

Operational flexibility. Any operating equipment shall consider its negative shape, and the impact on the capture efficiency when the gas flow is greater than or less than the design value; Similarly, if the dust concentration is unstable or continuously higher than the design value, it is also important to know how to operate.

Hydrophobicity. The purification efficiency of wet dust collector for hydrophobic dust is low, so it is generally not suitable for how to operate within the design value.

Cohesion. Wet dust collector can purify adhesive dust, but cleaning and cleaning shall be considered to prevent blockage.

corrosive. Anticorrosion measures shall be considered when purifying waste gas.

Water consumption. Consumption and discharge of water treatment sewage of dust remover, and anti freezing measures for water in winter.

Mud treatment. Mud treatment is an inevitable problem for wet dust collectors, so the harm of pollution should be minimized.

Operation and maintenance. Generally, avoid moving or rotating parts in the dust remover. Pay attention to the blockage caused by too little gas passing through the overflow section.

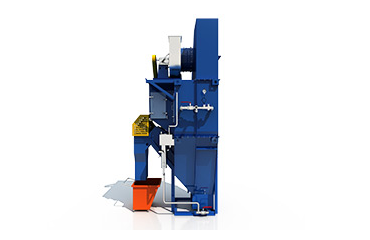

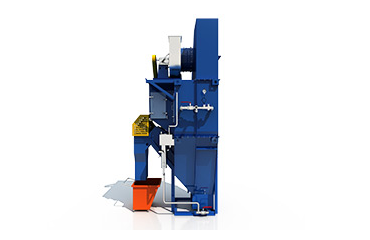

Spray scrubber

The spray scrubber can be used as a dust remover, as shown in the figure below. When the scrubber is used as a dust remover, the diameter of the droplets is 500~1000 m, and its main technical performance is as follows:

The empty tower speed is 0.6~1.5m/s.

Water air ratio (water consumption) 0.1~2.7 L/m3

Water spray pressure is 0.1-0.2mpa

Air resistance (excluding resistance of constant flow orifice and baffle) 250~500Pa;

Purification efficiency (dust particles below 10m) 70%.