Do you understand how the dust remover is classified, how it is distinguished, and how its economy is defined? Today's editor will solve this problem for you and talk about it from these aspects.

1. Dust removal efficiency

The dedusting efficiency refers to the ratio of the amount of dust collected by a deduster to the amount of dust entering the deduster. According to the total dust removal efficiency, it can be divided into: low efficiency dust remover (50~80%), medium efficiency dust remover (80~95%) and high efficiency dust remover (more than 95%).

2. Dust prevention function

Resistance is the pressure loss when air passes through the dust remover. According to the size of resistance filter, it can be divided into: low resistance filter( δ P<500pa), resistance filter( δ P=500~2000 (pa) and high resistance dust collector( δ P = 2000 ~ 20000 pa)。

3. Economy

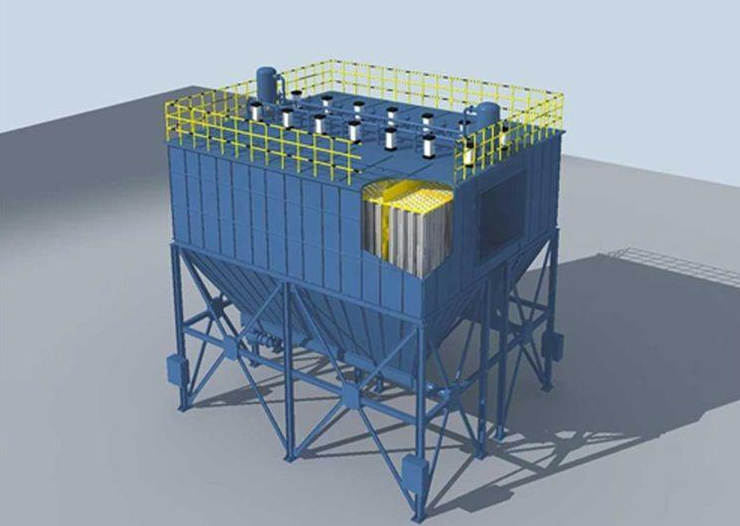

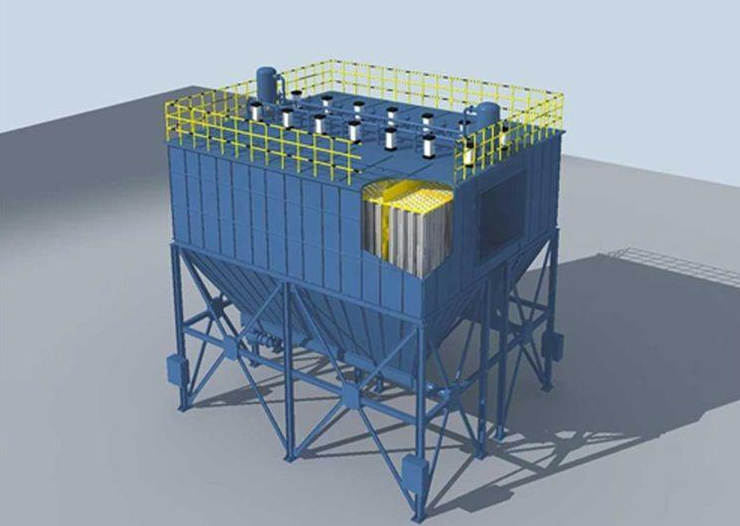

Economy is one of the important indexes to evaluate the dust collector, including equipment cost and operation and maintenance cost. In various dust collectors Electrostatic precipitator The equipment cost is the highest, and the bag filter, venturi filter and cyclone filter are the smallest. The electrostatic precipitator: the dust removal efficiency is high, generally above 99%, and the design efficiency is as high as 99.99%, commonly known as "water filter": Wet dedusting The filter efficiency can reach more than 85%, the granite water film+vortex plate integrated desulfurization dust remover>>80%, and the desulfurization and dust reduction can reach more than 95%.